products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

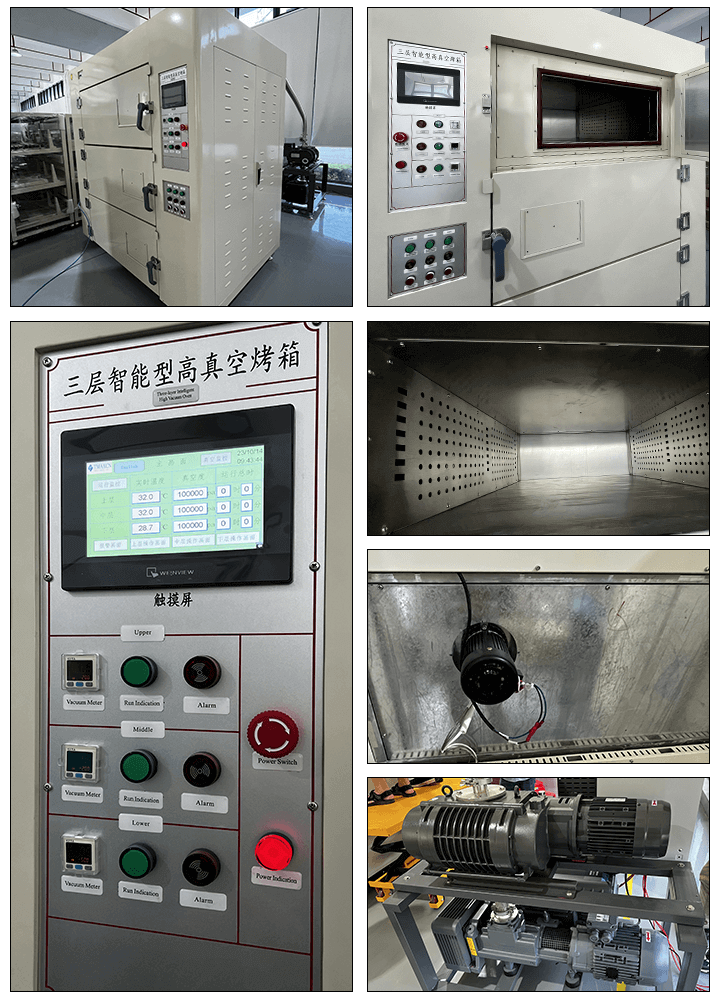

Three-Layer Single-Door Vacuum Oven

Model Number:

TMAX-ZRJX-310-AInput Power:

4.5KW*3Dimension(L*W*H):

height:300 mm width: 800 mm depth: 600 mm*3 layersNet Weight:

700kgCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Four-Chamber Vacuum Oven for Battery Electrodes BakingNext:

1600 m³/h NMP Solvent Recovery System for Battery Pilot Production Line

Three-Layer Single-Door Vacuum Oven

1. Application Scope:

Suitable for baking lithium-ion battery electrodes, cells, and pre-injection batteries

2. Configuration:

A. Oven Chamber: Made of 3.0 mm imported 304 stainless steel, with stiffeners made of the same material

B. Frame: Made of 1.5 mm and 2.0 mm high-quality cold-rolled steel plates, composed of double insulation layers, using aluminum silicate cotton, aluminum foil cotton, and sound insulation cotton as layered materials

C. Control System: Consists of PLC, touchscreen, pressure sensor, high vacuum baffle valve, solid-state relay, temperature controller, and solenoid valve group

D. Hardware Components: Includes door, rear cover, vacuum pipes, and other stamped parts

3. Machine Features:

A. Double-layer thermal insulation structure with external surface temperature ≤ 45°C (excluding glass door)

B. High vacuum pneumatic baffle valve with three independent layers controlled separately

C. Touchscreen display, fully automatic cycling control, returning to vacuum pressure hold upon completion; digital display for safety temperature

D. Resilient double-layer glass door, with three-layer pressure detection and over-pressure protection

E. Equipped with multi-stage over-temperature protection device, effectively preventing temperature runaway and improving temperature safety control precision

F. Touchscreen centralized control, easy and reliable operation; program controller adopts PLC, stable and reliable performance

G. Each oven layer is individually controlled, with separately configurable total baking time, cycle time, vacuum time, and drying time. Once parameters are set, the system enters the automatic baking program at the press of a button. Upon completion of the baking cycle, the oven automatically shuts down. If the temperature exceeds the safety threshold, the system automatically alarms, the red warning light is activated, heating stops, and an alarm message appears on the display

H. The system can automatically stop nitrogen filling when the pressure reaches a set value between –0.1 MPa and –0.02 MPa

I. During normal operation, alarm messages and fault causes are displayed on the screen

J. Vacuum pipelines are corrosion-resistant

L. Program interlocks prevent gas crossover between layers

4. Technical Parameters:

No. |

Item |

Technical Parameter |

1 |

Heating Principle |

Independent heating for three layers |

2 |

Power Supply |

380V, 50Hz, 9KW |

3 |

Gas Source |

Dry gas: 0.1–0.2 MPa / Vacuum: –0.095 to –0.1 MPa / Compressed air: 0.4–0.5 MPa |

4 |

Temperature Range |

Room temperature to 150°C |

5 |

Vacuum Degree |

When reaching –0.1 to –0.09 MPa, digital display shows ≥95% pressure hold for 24H |

6 |

Display Accuracy |

Set value vs. stabilized value deviation ≤ ±1°C |

7 |

Insulation Performance |

Outer wall temperature ≤ 45°C (excluding glass door) |

8 |

Temperature Uniformity |

Within 50 mm from the chamber wall: ±4°C (vacuum), ±3°C (atmospheric) |

9 |

Temperature Crossover Between Layers |

≤25°C (when adjacent layer is heated to 100°C, other layers rise ≤25°C) |

10 |

Response Time |

Display reaches set temperature ≤ 30 min; core temp stabilizes in 60–100 min (no load) |

11 |

Chamber Size |

330 mm (H) × 830 mm (W) × 800 mm (D) × 3 layers |

12 |

External Dimensions |

1970 mm (H) × 1250 mm (W) × 1100 mm (D) |

5. Electrical Configuration:

No. |

Component |

Specification |

1 |

PLC |

Zhongshan Zhida |

2 |

Touchscreen |

7-inch LCD Kunlun Tongtai |

3 |

Temperature Controller |

Digital intelligent controller / Microcomputer PID auto-tuning |

4 |

Control Mode |

PID + SSR (thyristor), Shanghai Yatai |

5 |

Over-temperature Protection |

Shanghai Yatai controller |

6 |

Temperature Sensor |

K-type thermocouple |

7 |

Vacuum Gauge |

Digital vacuum gauge –101.0 to +101.0 kPa, universal pressure gauge, Taiwan Jingdeng |

8 |

Vacuum/Nitrogen Valve |

High vacuum baffle valve |

9 |

Alarm |

Sound and light alarm |

10 |

Heating Tube |

Changcheng Electric Heating |

11 |

Control Method |

Each chamber operates independently. Heating, vacuuming, and nitrogen filling controlled by PLC in automatic cycle mode. All segments are operated via touchscreen |

6. Installation Conditions:

6.1 The front of the oven must be at least 1500 mm from the wall; sides and rear must be at least 500 mm

6.2 Installation Area Conditions (Provided by Customer):

l 6.2.1 Power Supply: Three-phase five-wire, frequency: 50 ±1Hz

l 6.2.2 Vacuum: Pressure –0.1 MPa, vacuum pipe DN20

l 6.2.3 Nitrogen: Pressure 0.1–0.2 MPa, gas pipe φ12 mm

l 6.2.4 Compressed Air: Pressure 0.4–0.6 MPa, gas pipe φ8 mm

6.3 Power Consumption:

l 6.3.1 Maximum consumption: ≤9 KW/hour

l 6.3.2 Average consumption: ≤2.5 KW/hour

6.4 Environmental Requirements:

l 6.4.1 Temperature: –5 to 35°C; Humidity: ≤40%

l 6.4.2 No flammable/explosive gases, liquids, or solids in surrounding environment

l 6.4.3 It is strictly prohibited to bake flammable materials, combustible gases, or explosive substances inside the oven

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com