products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Two-Chamber Vacuum Oven for Lithium-Ion Electrode Roll Baking

Model Number:

TMAX-ZRJX-210-BType:

AutomaticCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5-650L Planetary Dispersion Vacuum MixerNext:

Three-Layer Single-Door Energy-Saving Vacuum Drying Oven

1. Scope of Application:

Suitable for baking entire rolls of lithium-ion battery electrode.

2. Configuration

A. Chamber Body: Made of 3.5mm imported 304 stainless steel, reinforced ribs are made of the same material.

B. Frame: Constructed from 1.5mm and 2.0mm high-quality cold-rolled steel plates, composed of two-layer insulation, with layered construction of aluminum silicate wool, aluminum foil wool, and soundproofing wool.

C. Hot Air System: Each layer consists of fan, heating box, air duct, and air pipe, ensuring temperature uniformity.

D. Control System: Composed of PLC, Weinview touchscreen, KITA pressure sensor, high vacuum gate valve, solid-state relay, temperature controller, electromagnetic valve group, etc.

E. Hardware Components: Includes doors, rear cover, vacuum pipes, and other stamped parts.

3. Machine Features

A. Fully sealed heating channels with breathing-type heating process, high efficiency and energy-saving, high temperature accuracy.

B. High-vacuum pneumatic gate valve, independently controlled dual-chamber isolation.

C. Standardized six-fold high-performance safety protection across all models.

D. Aluminum alloy doors, elastic double-layer glass doors, excellent heat retention and explosion-proof performance, equipped with dual-layer pressure detection and overpressure protection.

E. Equipped with 7-inch full-color touchscreen HMI system across all models, elegant and intuitive.

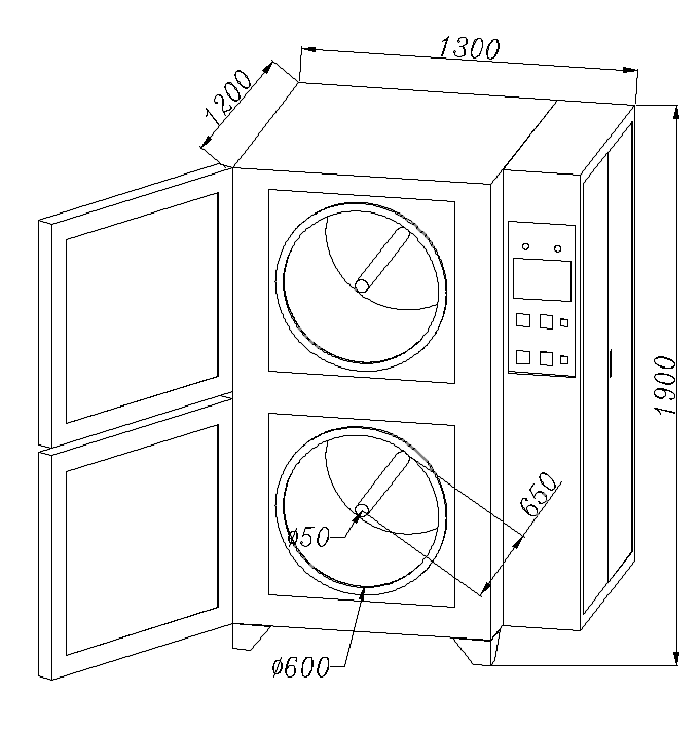

G. Material Loading Method: Suspended on a ∅63mm hanging shaft in the center of the inner chamber, maximum load ≤150kg.

H. Chamber Structure: Double-door, single-opening door.

I. Insulation Structure: Uses high-density aluminum silicate insulation wool, double-layer thermal insulation, external temperature below 45°C (excluding glass doors).

J. Heating Method: Electric heating control, external loop-type hot air circulation.

K. Heating Structure: Uses O-type external circulation – air outlet on the left, suction on the right, to achieve temperature uniformity.

L. Touchscreen display, automatic circulation and control, automatically returns to vacuum holding at the end; digital display of safety temperature.

M. Equipped with multi-level over-temperature protection, effectively prevents temperature control failure and enhances accuracy of protection.

N. Control panel adopts centralized touchscreen operation, convenient and reliable control. Program controller adopts PLC control, stable and reliable operation.

O. The two-barrel oven is independently controlled, can set total baking time, cycle time, vacuum time, drying time separately. After setting parameters, pressing the auto button will enter the automatic baking program. When the baking time is reached, the system will automatically shut down. If the temperature exceeds the safety limit, it will automatically alarm, the red indicator light turns on, heating stops, and the alarm information is displayed on the screen.

P. During normal operation, fault warnings and causes can be displayed on the screen in real-time.

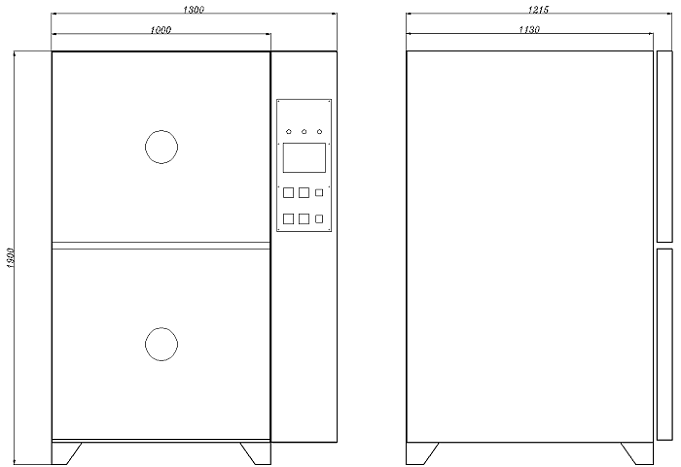

4. Technical Specifications

No. |

Item |

Specification |

1 |

Heating Principle |

Independently heated dual-barrel external hot air circulation |

2 |

Power Supply |

380V 50Hz 12KW |

3 |

Gas Supply |

Dry gas: 0.1–0.2MPa / Vacuum: -0.095 to -0.1MPa / Compressed air: 0.4–0.5MPa |

4 |

External Interface Specs |

Vacuum: DN20 hose barb; Nitrogen: ∅12 air pipe; Compressed air: ∅8 air pipe |

4 |

Temperature Range |

Room temperature to 150°C |

5 |

Vacuum Level |

At -0.09 to -0.1MPa, pressure-holding loss ≤ 3% in 24H |

6 |

Display Error |

Difference between set value and stabilized value ≤ ±0.5°C |

7 |

Insulation Performance |

Outer wall temperature ≤ 45°C (excluding glass doors) |

8 |

Internal Temperature Variance |

At 50mm from chamber wall: ≤ ±3.5°C under vacuum; ≤ ±2.5°C at atmospheric pressure |

9 |

Temperature Crosstalk |

≤30°C (adjacent layer heating to 100°C causes ≤30°C increase above ambient) |

10 |

Response Time |

30 minutes to 85°C on display; internal uniformity in 45–60 minutes |

11 |

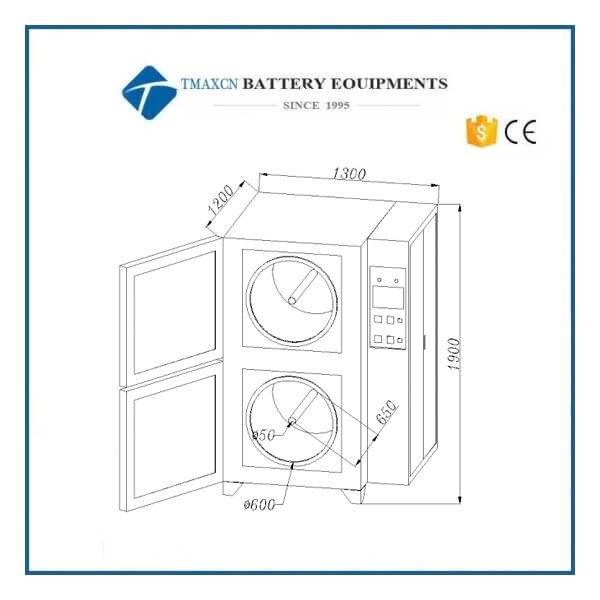

Chamber Size |

ZRDB-210: ∅600 × 700 depth × 2 barrels |

12 |

External Dimensions |

ZRDB-210: 1900H × 1300W × 1215D (mm) |

5. Electrical Configuration

No. |

Item |

Specification |

1 |

PLC |

Wecon (Fujian) |

2 |

Touchscreen |

7-inch LCD color screen, Wecon |

3 |

Temperature Controller |

Digital intelligent PID auto-calculation temp controller |

4 |

Temperature Control Mode |

PID + SSR (thyristor), Shanghai Yatai |

5 |

Over-Temperature Prot. |

Shanghai Yatai temp controller |

6 |

Temperature Sensor |

K-type thermocouple |

7 |

Vacuum Gauge |

Digital vacuum gauge, ±101.0kPa, Jian Deng (Taiwan) |

8 |

Vacuum/Nitrogen Valves |

High vacuum gate valve |

9 |

Alarm |

Audio-visual alarm |

10 |

Heating Tubes |

Best |

11 |

Control Mode |

PLC automatic program control, 7-inch color screen HMI |

6. Six-Fold Safety Protection

1. Explosion-proof door, never ruptures; equipped with overpressure self-release to protect operator safety.

2. Dual-layer over-temperature protection in working chamber (to protect products); power is cut off automatically when over-temperature is detected.

3. Over-current and short circuit protection for control system.

4. Over-current and short circuit protection for heating tubes and motors.

5. When chamber is overcharged, the system will automatically shut off nitrogen & dry gas inlets, saving gas and reducing losses.

6. Independent alarm system: audio-visual warning is issued when baking time is reached, alerting operators.

7. Installation Conditions

A. Oven must be installed ≥1500mm away from front wall, and ≥300mm away from left, right, and rear walls. The user must provide an independent power switch and be responsible for external power connection.

B. Installation Site Conditions (provided by customer):

1. Power Supply: Three-phase five-wire, frequency: 50 ±1Hz

2. Vacuum Requirement: -0.1MPa, vacuum pipe DN20 hose barb

3. Nitrogen: Pressure 0.1–0.2MPa, nitrogen pipe ∅12 air pipe

4. Compressed Air: 0.4–0.5MPa, ∅8 air pipe

![]()

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com