products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Vanadium Redox Flow Cell Single Split Unit for Battery Research

Model Number:

TMAX-EQ-VRB-C-LDCompliance:

CE CertifiedWarranty:

1 yearPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5T Manual Mechanical Press/Compressing Jig for Flow CellNext:

Complete Vanadium Redox Flow Cell Testing Package

Vanadium Redox Flow Cell Single Split Unit for Battery Research

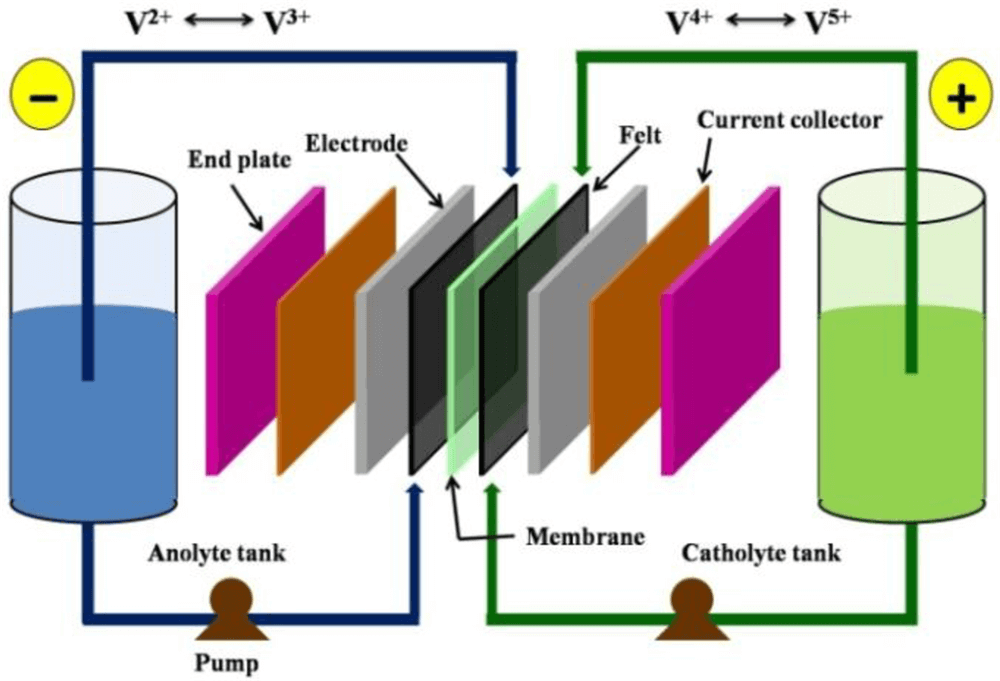

EQ-VRB-C is splitable single unit flow cell for Vanadium Redox Flow Battery research; a battery technology which takes advantage of eliminating the use of rare earth metals. Most importantly, this battery kind holds the potential to be vastly scaled up for industrial applications while incurring a lower cost increase -- the storage capacity is scaled up by implementing a larger electrolyte storage tank (compared to lithium-ion cells in which the amount of active materials on electrodes need to be increased and are more costly to produce). Moreover, this type of battery is capable of being charged and discharged for over 10 times the life cycle of lithium ion cells with no capacity loss.

This split test cell features easy and fast assembly with convenient part replacement to facilitate research for flow cell cathode and electrolyte solutions.

Product parameters

Features: |

· Single cell voltage range: 1.2V ~ 1.6V (depending on Vanadium electrolyte composition) · Cell current density: 40 ~ 100 mA / cm^2 ( maximum 4.9A of possible current draw for a 7cm x 7cm reactive area) · Manifold Blocks are made of anti-corrosive PTFE materials to withstand acids · Large reactive area provides uniform and reliable test data · Cathode materials are changable according to the test conditions · Easy assembly and disassembly |

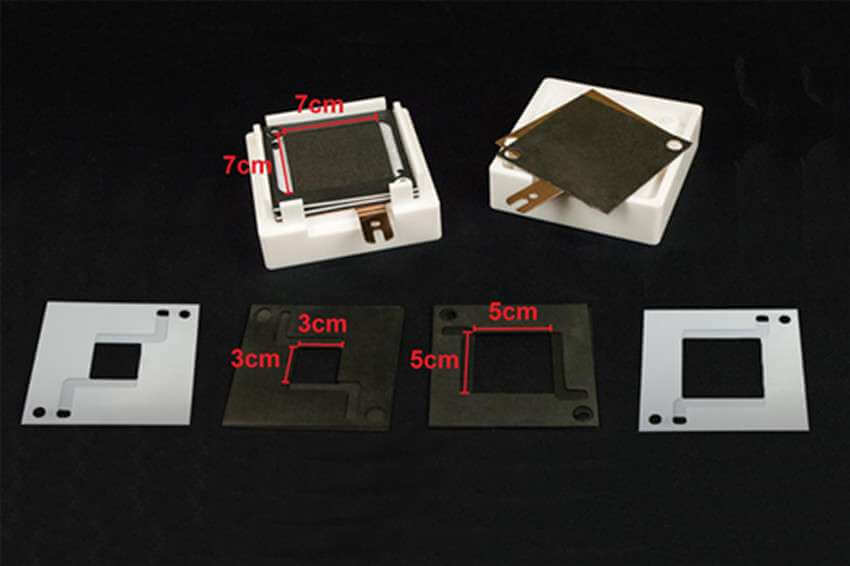

Reactive Area - Multiple Configurations |

· Standard cell comes with 3 interchangeable frames and gaskets for testing multiple parameters (please click the bottom left picture below for details): o 7x7cm o 5x5cm o 3x3 cm · Custom reactive area sizes up to 20cm x 30cm can be requested at an extra cost |

Compression Pressure |

· 87 PSI (0.6Mpa), ~300KG Force is recommended · 116 PSI (0.8Mpa) Max. |

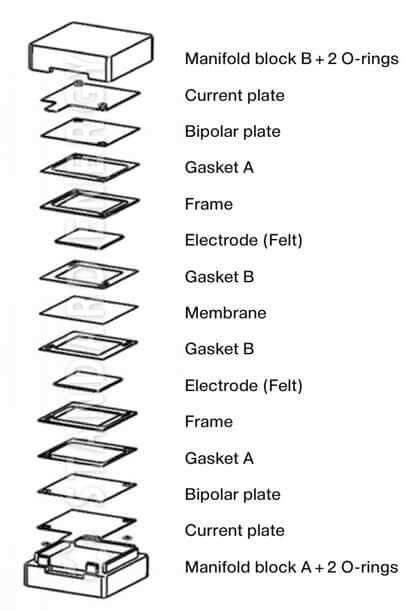

Unit Cell Internal Structure (all components are included) |

All components, Manifold Blocks, Current Plates, Bipolar Plates, Gaskets, Frames, Carbon Felts, Membranes, O-Rings, liquid inlet and outlet ports, are included for immediate use. Please click here to order extra Internal Components if it is needed.

|

Bipolar Plates |

· High electrical conductivity, chemical resistance, and high mechanical strength for toughness · These highly flexible plates offer performance comparable to conventional graphite plates BUT have excellent resistance to breakage and have less defects · Only ~0.7mm in thickness, this keeps cells thinner when stacked compared to graphite plates ( porous and brittle in nature; needs to be thick structurally) · Needs frequent replacement, please order from the "Related Products" category below |

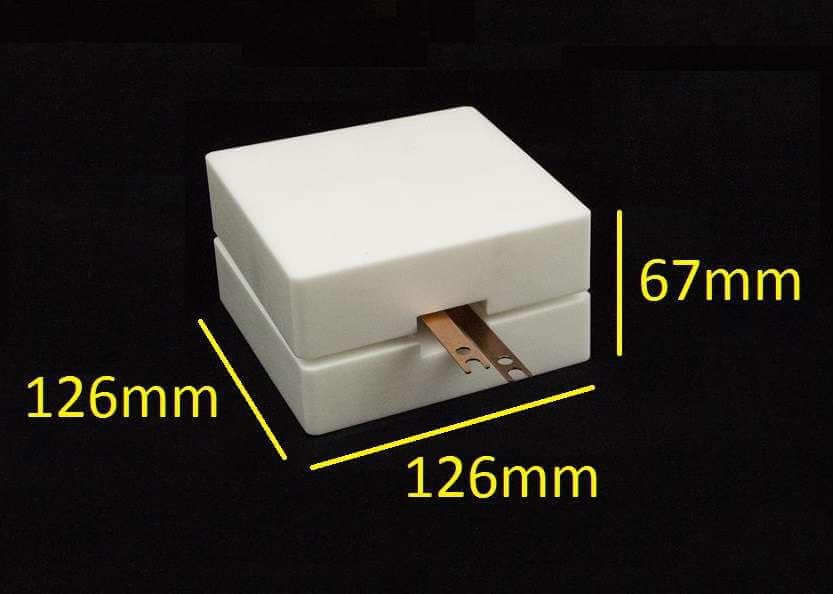

External Dimensions |

· 126mm (L) x 126mm (W) x 67mm (H)

|

Application Notes Photo Credit: Rahman, F.; Skyllas-Kazacos, M. Vanadium redox battery: Positive half-cell electrolyte studies. J. Power Sources 2009, 189, 1212-1219. |

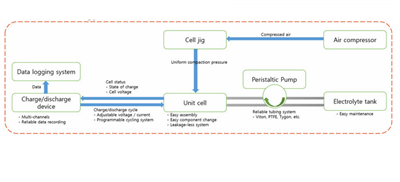

Procedure for Testing Flow Cell -- click the picture to enlarge: · A jig or pressing machine is required to tightly press the cell together in order to suppress leakage of electrolyte solutions during live tests. Please order a hydraulic jig separately from below or use your own jig -- WARNING: Never exceed a max. pressure of 0.8MPa to avoid damage to the flow cell · Peristaltic pump and battery analyzer are also available for making a low-cost DIY Flow Battery test system |

Optional Accessory |

· For a convenient electrolyte delivery to the flow cell, the anti-corrosive tanks feature easy tube connectors and can be seated onto a jig to prevent from falling over. Please click here to learn more on the product page

· You may also consider alternative jigs below: ·

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com