products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Vertical Square Size Planetary Ball Mill Machine

Model Number:

TMAX-DSP-LBPBM05ACompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Vertical Square Size Planetary Ball Mill Machine

1. Brief introduction of vertical square planetary ball mill

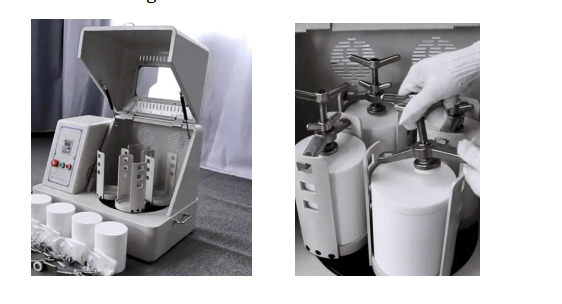

Vertical square planetary ball mill is a necessary device for mixing, fine grinding, small sample preparation, new product development and small batch production of high-tech materials. Our planetary ball mill is small in size, full in function, high in efficiency and low in noise. It is an ideal equipment for scientific research institutions, colleges and universities, and enterprise laboratories to obtain research samples (four samples can be obtained at the same time for each experiment). It is equipped with a vacuum ball mill tank, which can grind test samples under vacuum.

2. Application

Vertical square planetary ball mill is widely used in geology, mineral industry, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments. It is suitable for electronic ceramics, structural ceramics, magnetic materials, lithium cobaltic acid, lithium manganate, catalyst, fluorescent powder, long afterglow phosphor, rare earth polishing powder, electronic glass powder, fuel cell, zinc oxide varistor, piezoelectric ceramics, etc Ceramics, nano materials, wafer ceramic capacitors, MLCC, thermistor (PTC, NTC), ZnO varistor, dielectric ceramics, alumina ceramics, zirconia ceramics, fluorescent powder, zinc oxide powder, cobalt oxide powder, Ni Zn ferrite, Mn Zn ferrite and other products.

3. Features

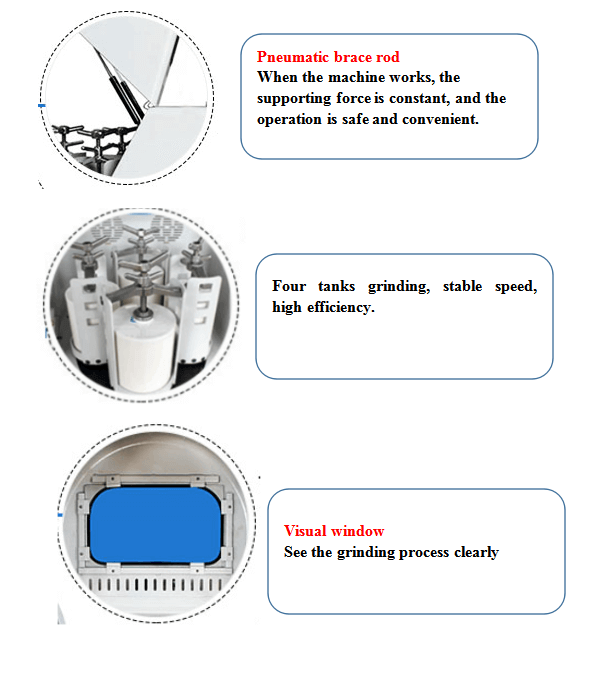

The equipment shell adopts square design elements, high-precision die stamping, generous and delicate, high-end and stable; the machining parts adopt numerical control processing technology, the planetary disk is integrally cast and formed, and the transmission gear adopts precision gear of special material to ensure the stable and quiet operation of the equipment at high speed; the grinding can pressing device is convenient, safe and reliable.

4. Specifications

Transmission |

Gear transmission |

Work |

Two or four tanks simultaneously milling |

Max sample loading capacity |

2/3 of Tank volume |

Tank volume |

Each tank :0.05L-50L, total volume :0.2L-20L |

Feed size |

Soil material ≤10mm, other material ≤3mm |

Discharge size |

Mix 0.1um |

Speed ratio (revolution: Rotation) |

1:2 |

Speed (rotation) |

0-900 r / min (ordinary), 0-1400 rev / min (high-speed type); |

Velocity modulation way |

Stepless speed regulation Speed Accuracy 0.2 rev / min; |

Programmable control |

Ball mill using high-tech micro-computer chip control, can set the program forward and backward alternately run (0-999min) and forward, pause, reverse, pause, forward (0-999min) alternate operation, particularly suitable cooling or if you need to run it intermittently |

Maximum continuous working time (full load) |

72 hours (timer 0-9999h) |

Various optional materials of milling tank |

Agate, alumina corundum ceramics, zirconia ceramics, silicon nitride ceramic, silicon carbide ceramic, stainless steel, high wear-resistant steel, manganese steel, nylon, PTFE, polyurethane, carbide, crystal glass, and other special metal materials and so on; |

Optional milling media |

Agate, alumina, zirconia, silicon nitride, silicon carbide, stainless steel, high wear-resistant steel, manganese steel, nylon, polyurethane, carbide, glass, and other special metals, etc. |

Optional milling environmental conditions |

Vacuum ball milling, the inert gas milling, cold milling, ball milling high temperature |

We can provide different capacity of planetary ball mill according to your requirement.

Model |

Power supply |

Motor power Converter power |

Operating time setting (min) |

Positive and negative alternating operation time(min) |

Adjustable speed Revolution (rpm) |

Adjustable speed Rotation (rpm) |

Noise <db |

XQM-0.2 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-0.4 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-1 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-2 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-4 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-6 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

XQM-8 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

60db |

XQM-10 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

60db |

XQM-12 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

65db |

XQM-20 |

380V 50HZ |

4KW |

1-9999 |

1-999 |

25-215 |

50-430 |

65-db |

XQM-40 |

380V 50HZ |

5.5KW |

1-9999 |

1-999 |

20-195 |

40-390 |

68db |

XQM-60 |

380V 50HZ |

7.5KW |

1-9999 |

1-999 |

27-174 |

40-260 |

68db |

XQM-100 |

380V 50HZ |

11KW |

1-9999 |

1-999 |

27-160 |

40-240 |

68db |

Model |

Capacity |

Specification of milling tank |

Qty |

XQM-0.2 |

0.2L |

50ml |

4 set |

XQM-0.4 |

0.4L |

50ml-100ml |

4 set |

XQM-1 |

1L |

50ml-250ml |

4 set |

XQM-2 |

2L |

50ml-500ml |

4 set |

XQM-4 |

4L |

250ml-1L |

4 set |

XQM-6 |

6L |

lL-1.5L |

4 set |

XQM-8 |

8L |

1L-2L |

4 set |

XQM-10 |

10L |

1L-2.5L |

4 set |

XQM-12 |

12L |

1L-3L |

4 set |

XQM-20 |

20L |

2L-5L |

4 set |

XQM-40 |

40L |

5L-10L |

4 set |

XQM-60 |

60L |

10L-15L |

4 set |

XQM-100 |

100L |

20L-25L |

4 set |

Product Detail Images

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com