products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

1 to 600L Stirring Ball Mill with Automatic Lifting Stirring Rod

Model Number:

TMAX-JMInput Power:

0.75KWNet Weight:

70KGCompliance:

CEPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

1 to 600L Stirring Ball Mill with Automatic Lifting Stirring Rod

Product introduction

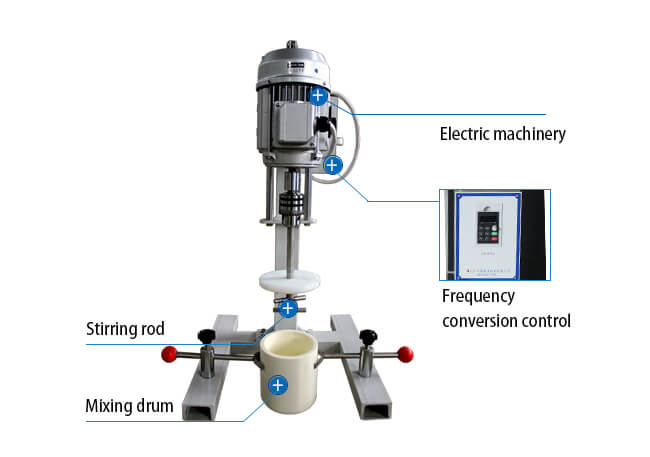

The stirred mill mainly consists of a stationary grinding cylinder filled with small-diameter grinding media, a stirring device and other auxiliary devices (such as: It is composed of a circulation device, a cooling device, a timing system, a speed regulation control system, etc. It features high grinding efficiency, fine grinding particle size, and can well meet various process parameter requirements, simulate various indicators in production. Meanwhile, due to its advantages of small batch size, low power consumption and low price, it is an optional equipment for schools, research institutions and companies to conduct research on grinding processes, new materials and coatings. It is widely applied in the production fields of various fine ground powders such as zirconium silicate, zirconia, alumina, ceramics, chemicals, electronic materials, magnetic materials, papermaking, coatings, non-metallic minerals, new materials, paints, graphite, calcium carbonate, and pharmaceuticals.

Working Principle

When machine rotates with high speed under driving of main axis and grind media move irregularly at the same time, the grind material can be crushed, ground and sheared into fine granularity powder. The size, shape and matching ratio of the grind media can affect the grinding result. Generally speaking, the bigger the mill media is, the finer the grinding powder is. A proper match ratio of grind medias and proper adjustment of rotation speed can get better grinding effect.

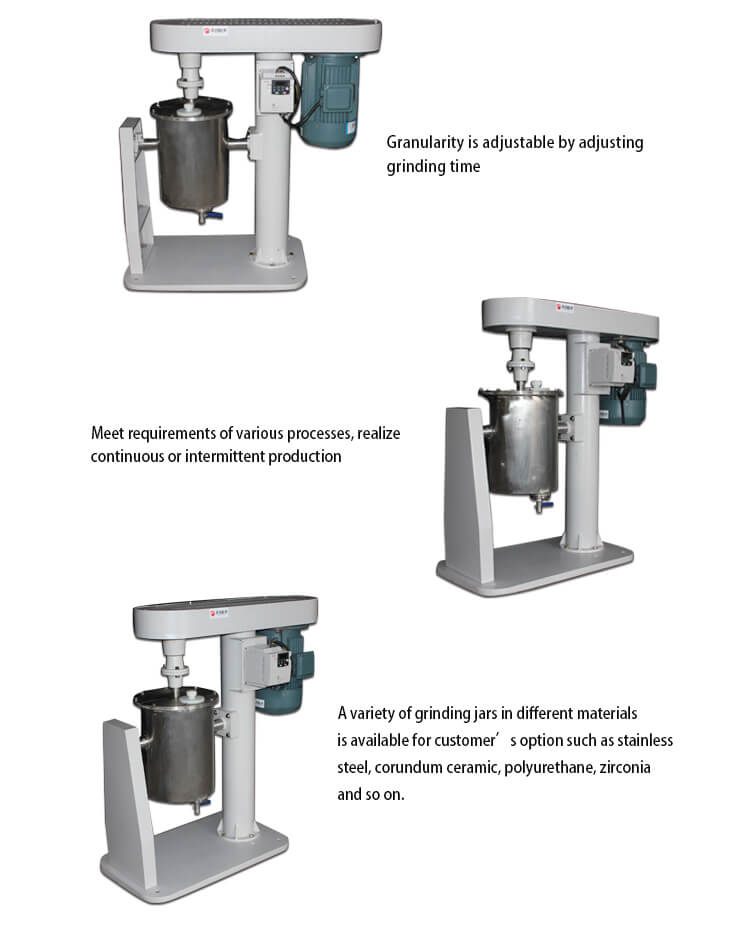

Product feature

1. High utilization rate of energy, saving energy.

2.Granularity is adjustable by adjusting grinding time.

3.Less vibration, low noise.

4.Simple structure, easy operation.

5.Meet requirements of various processes, realize continuous or intermittent production.

6.Jar with jacket, easy to control the grinding temperature .

7.Customized service is available. Special functions such as timing, speed adjusting, recycling, temperature controlling can be selected and ordered.

8.A variety of grinding jars in different materials is available for customer’s option such as stainless steel, corundum ceramic, polyurethane, zirconia and so on.

Product Parameter

Main Parameters of Stirred Ball Mill |

|||||||||

Model No. |

Rotate Speed |

Volume |

Load Capacity |

Power Supply |

Available Jars |

Feed Size |

Output Granularity |

Speed Control Mode |

Category |

TMAX-JM-1L |

50-1400 |

1 |

0.35 |

0.37KW/220V |

Stainless steel |

≤5mm |

≤1µm |

Frequency speed adjuster |

Laboratory Scale |

TMAX-JM-2L |

50-1400 |

2 |

0.7 |

0.37KW/220V |

≤5mm |

≤1µm |

|||

TMAX-JM-3L |

50-1400 |

3 |

1.05 |

0.37KW/220V |

≤5mm |

≤1µm |

|||

TMAX-JM-5L |

60-560 |

5 |

1.75 |

0.75KW/220V |

≤5mm |

≤1µm |

Frequency speed adjuster |

Small Type |

|

TMAX-JM-10L |

60-560 |

10 |

3.5 |

1.5KW/220V |

≤10mm |

≤1µm |

|||

TMAX-JM-15L |

60-380 |

15 |

5.25 |

2.2KW/380V |

≤10mm |

≤1µm |

|||

TMAX-JM-20L |

60-380 |

20 |

7 |

2.2KW/380V |

≤10mm |

≤1µm |

Light Type |

||

TMAX-JM-30L |

60-310 |

30 |

10.5 |

3.0KW/380V |

Carbon steel |

≤10mm |

≤1µm |

||

TMAX-JM-50L |

60-140 |

50 |

17.5 |

4.0KW/380V |

≤10mm |

≤1µm |

|||

TMAX-JM-100L |

60-140 |

100 |

35 |

7.5KW/380V |

≤20mm |

≤1µm |

Industrial Type |

||

TMAX-JM-200L |

60-110 |

200 |

70 |

11KW/380V |

≤20mm |

≤1µm |

|||

TMAX-JM-300L |

60-110 |

300 |

100 |

15KW/380V |

≤20mm |

≤1µm |

|||

TMAX-JM-500L |

60-90 |

500 |

170 |

18.5KW/380V |

≤20mm |

≤1µm |

|||

TMAX-JM-600L |

60-90 |

600 |

200 |

22KW/380V |

≤20mm |

≤1µm |

|||

Product picture

Lab Stirred Ball Mill TAMX-JM-(1-3)

Small Stirred Ball Mill TAMX-JM-(5-15)

Light Type Stirred Ball Mill TAMX-JM-(20-50)

Production Type Stirred Ball Mill TAMX-JM-(100-600)

Production Type Stirred Ball Mill TAMX-JM-(100-600)

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com