products categories

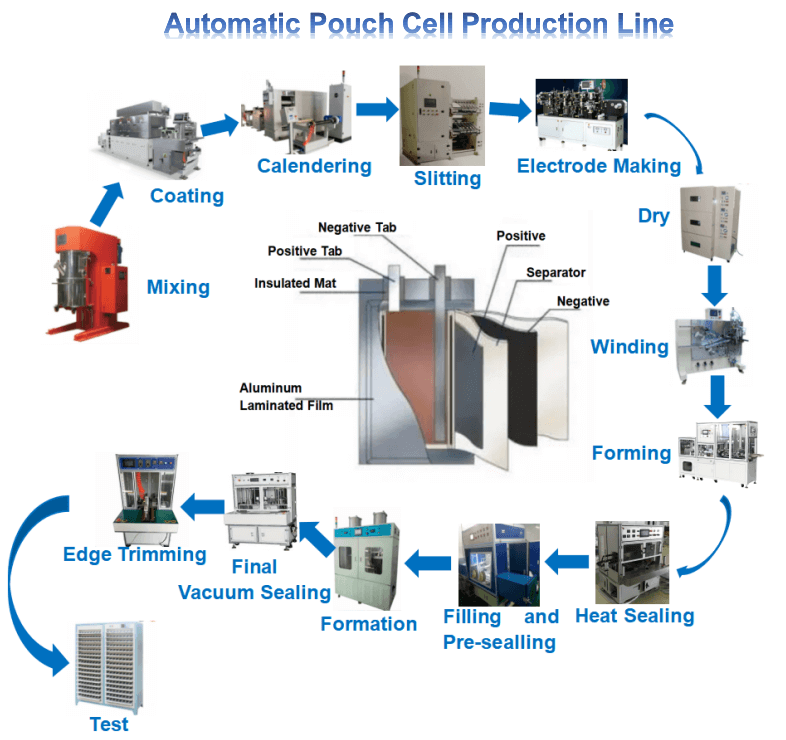

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

180-Type Automatic Electrode Stacking Machine – Separator Handling & Auto Taping (No Tail Turning)

Model Number:

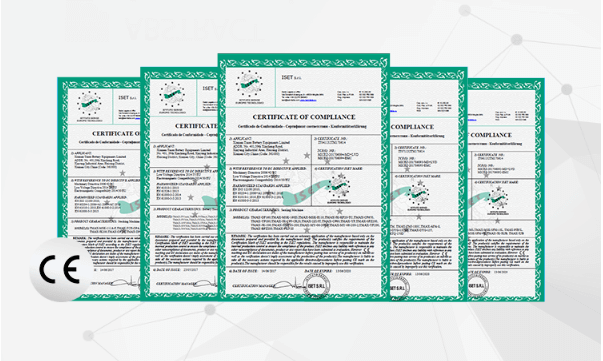

TMAX-SS180Compliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

200-Type Automatic Single Workstation Electrode Stacking Machine with CCD Positioning – Tail Wrapping & Taping IncludedNext:

Fully Automatic Z-Fold Double Working Station Stacking Machine For Prismatic Cells

180-Type Automatic Electrode Stacking Machine – Separator Handling & Auto Taping (No Tail Turning)

I. Function Overview

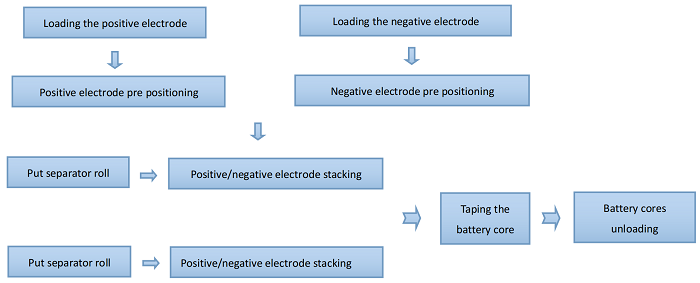

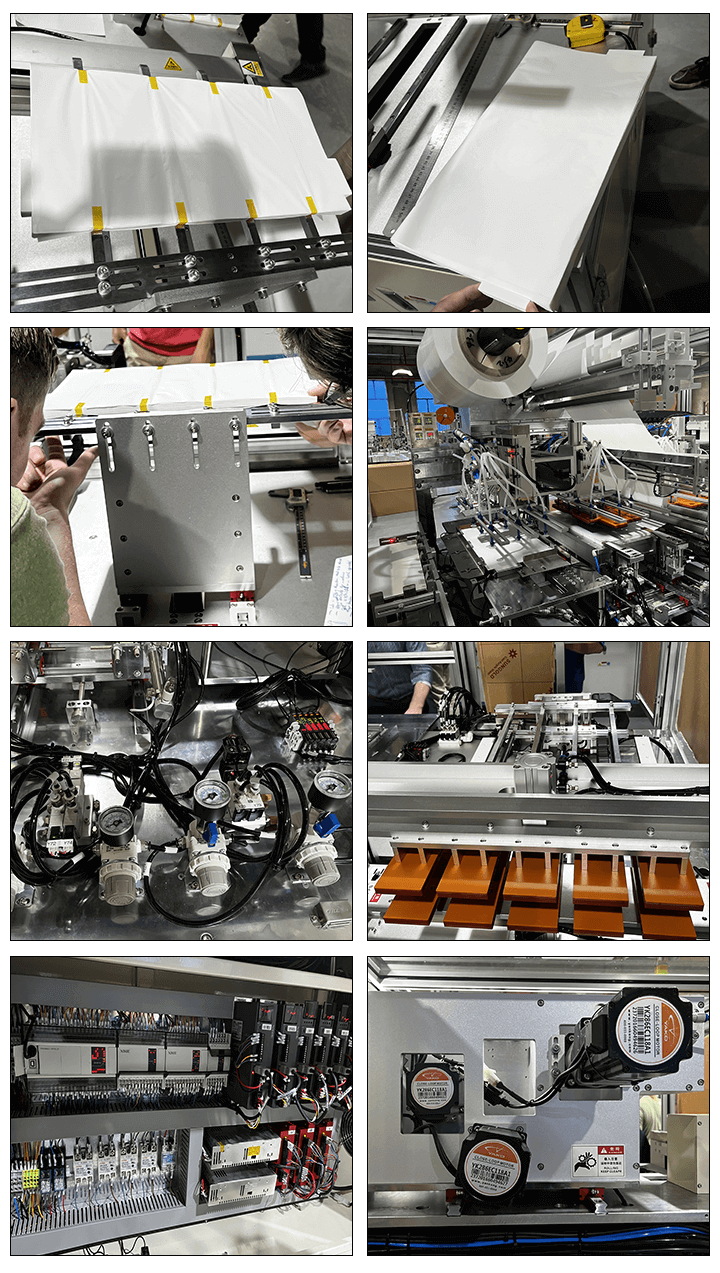

The separator is actively unwound, guided onto the stacking platform via a tension mechanism, and moved back and forth by the platform to place the electrodes. Two robotic arms with suction cups separately pick up positive and negative electrodes from the two left-side feed hoppers, then stack them onto the platform after precise positioning. Upon completion of stacking, the separator is cut, and a robotic arm transfers the cell to the adhesive tape station for automatic taping. The next cell then starts automatic stacking. (No tail turning).

II. Basic Parameters

1. Dimensions: 1800mm (L) × 2100mm (D) × 1900mm (H) – subject to final design

2. Power Supply: 220V 50Hz, Power: 4500W, Weight: 2 tons

3. Air Source: 0.5MPa

4. Working Environment: Non-corrosive gas/liquid, non-explosive gas

5. Color: Supplier standard color (International Warm Grey 1C)

III. Technical Specifications

1. Applicable Specifications:

Length L: 150–280mm, Width W: 70–180mm, Thickness H: 5–25mm

Tab Length Q ≤ 25mm

2. Machine Speed: 1.5–1.6 s/pcs

3. Electrode and Separator Alignment Precision: Center offset ±0.3mm

4. Dust Protection: Feed hoppers and pre-positioning units are equipped with dust-proof mechanisms

5. Reliability: High-precision and frequently moving modules are secured with positioning pins

6. Multiple Sheet Detection: Detects and prevents stacking of missing or multiple sheets

7. Tab and Corner Defect Detection: Stops damaged electrodes from entering the stack

Cell Specifications

Item |

Spec |

Remarks |

|

Cell Length (L) |

150–280 mm |

|

|

Cell Width (W) |

70–180 mm |

||

Cell Thickness (T) |

5–25 mm |

||

Tab Exposure (L1) |

10–25 mm |

||

Tab Direction |

Opposite sides |

||

When Tab Opposed |

L+L1 ≤260 mm |

||

|

|

||

IV. Standard Components

No. |

Component |

Qty |

Description |

1 |

Electrode Hopper Auto Feeder |

2 |

Special slot-in hoppers, adjustable range |

2 |

Electrode Feeding Assist Unit |

2 |

Brushes, vibrating mechanism, air blow, dust suction |

3 |

Electrode Lifting Mechanism |

2 |

Ensures reliable pickup, stops for material shortage |

4 |

Separator Tension Unit |

1 |

Active unwinding, constant tension |

4.1 |

Separator Correction System |

1 |

Unwinding correction |

5 |

Mechanical Pre-positioning |

2 |

Precise mechanical positioning, dust suction |

5.1 |

Multi-sheet Detection |

2 |

Ultrasonic thickness detection |

6 |

Stacking Robot Arm |

2 |

Servo driven, accurate pick and place |

7 |

Suction Plate Assembly |

4 |

Vacuum nozzle and plate types |

8 |

Stacking Platform |

1 |

Servo driven, precision ball screw motion |

9 |

Separator Blowing Unit |

1 |

Air-blow for separator repositioning |

10 |

Cell Transfer Manipulator |

1 |

Transfers stacked cell to taping station |

11 |

Separator Cutting Mechanism |

1 |

Heat cutting knife, cuts to set length |

12 |

Tape Side Pasting Mechanism |

1 |

Four-side taping including tabs, configurable |

13 |

Automatic Unloading Unit |

1 |

Auto-stacking for batch removal |

14 |

Electrical Operation System |

1 |

Touch screen with emergency stop, power switch |

15 |

Control System |

1 |

Built-in electrical and pneumatic routing |

16 |

Machine Frame Base |

2 |

Color: PC White |

17 |

Dustproof Cover |

1 |

Aluminum and acrylic with interlock, emergency switch |

18 |

Dust Suction System |

1 |

Blower system for pre-positioning and hoppers |

19 |

Vacuum System |

/ |

Vacuum generator |

V. Main Component Configuration

1. Standard Parts List

No. |

Name |

Brand |

Remarks |

1 |

Cylinder |

AIRTAC |

|

2 |

Magnetic Switch |

AirTAC (TW) |

|

3 |

Linear Rail |

Dinghan |

|

4 |

Ball Screw |

TBI |

|

5 |

Servo Motor/Driver |

Qinglan/Yankong |

|

6 |

Solenoid Valve |

EMC |

|

7 |

PLC |

OMRON |

|

8 |

Sensor |

TELEY/Jiazun |

|

9 |

Optical Fiber |

Jinggong/Jiazun |

|

10 |

Touchscreen |

OMRON |

|

11 |

Ion Fan |

Domestic |

|

2. Changeover Parts List

No. |

Component Group |

Part Name |

Unit |

Qty |

Remarks |

1 |

Electrode Hopper |

Movable Plate |

Pcs |

4 |

Adjustable within range |

2 |

Pre-positioning Unit |

Adjustment Plate |

Pcs |

2 |

|

3 |

Stacking Arm |

Suction Plate |

Pcs |

2 |

|

4 |

Stacking Platform |

Compression Plate |

Pcs |

4 |

|

5 |

Cell Support Plate |

Pcs |

2 |

||

6 |

Unloading Unit |

Support Plate |

Pcs |

2 |

|

7 |

Taping Unit |

Assembly |

Set |

1 |

|

8 |

Others |

|

|

|

|

3. Consumable Parts List

No. |

Name |

Spec/Model |

Manufacturer |

Remarks |

1 |

Suction Nozzle |

Custom |

Machined |

Clean daily |

2 |

Compression Plate 1 |

Custom |

Machined |

10-day lead time |

3 |

Compression Plate 2 |

Custom |

Machined |

10-day lead time |

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Weekly maintenance required |

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Weekly maintenance required |

6 |

Foam |

— |

— |

Adheres to protect cell |

7 |

Teflon |

— |

— |

Adheres to protect electrode |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com