products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

3 in 1 Automatic Pouch Cell Edge Trimming Ironing Folding Machine(400)

Model Number:

TMAX-QZT400Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Rotary Vacuum Final Sealing MachineNext:

Automatic Pouch Cell Case Forming Machine

3 in 1 Automatic Pouch Cell Edge Trimming Ironing Folding Machine(400)

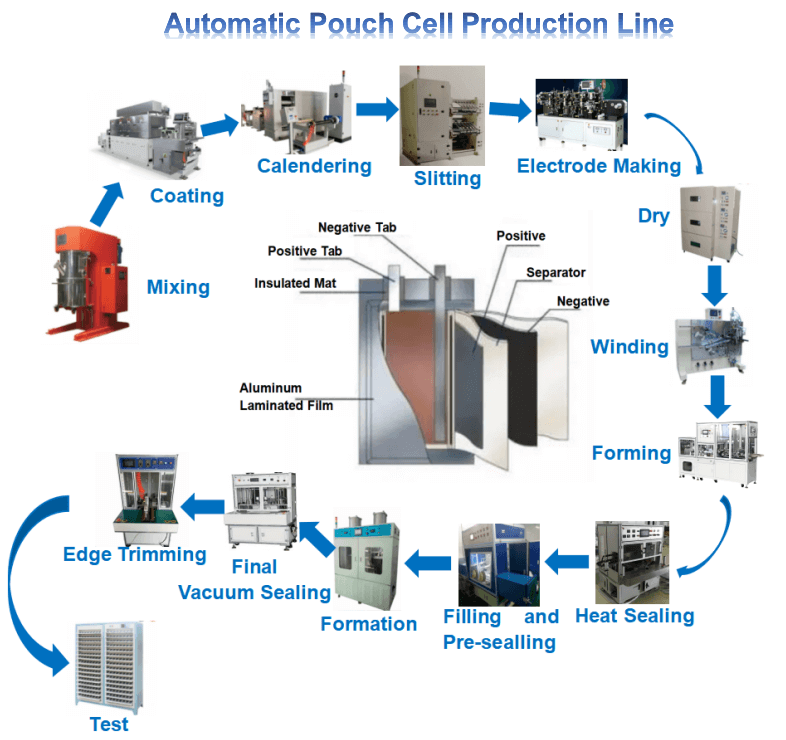

I. Equipment Action Principle

The cutting, folding and ironing three-in-one machine is a piece of equipment that integrates the three processes of cell trimming, edge folding and edge ironing.

Operating principle: this equipment consists of five mechanisms, namely the cell correction and positioning mechanism, the trimming mechanism, the edge-folding mechanism, the edge-ironing mechanism, and the robotic automatic pick-and-place device; after manual loading and cell correction/positioning, both hands press the dual start buttons, the equipment runs, and the cell undergoes trimming, edge folding and edge ironing. After ironing, the ironing mechanism opens, and the cell fixture returns to its starting position. The cell is removed manually.

II. Applicable Cells

Cell length: 20~~375 mm

Cell width: 15~~155 mm

Cell thickness: 5~15 mm

III. Equipment Diagram

IV. Equipment Operating Environment

1. Ambient temperature: 10~40 ℃

2. Relative humidity: 20~90 %

3. The gas supply must be a non-corrosive gas or liquid, and non-explosive gases.

Ⅴ. Equipment Feature

1. Supports both single and double folding operations.

2. Cutting knives rotate synchronously in opposite directions, ensuring high trimming accuracy; knife life exceeds 1.5 million cycles.

3. All four main mechanisms can be adjusted simultaneously for in‑and‑out motion, providing flexible operation.

4. Multiple products can be loaded at once, enhancing production efficiency.

5. Manual and automatic modes are available.

6. Position adjustments for each mechanism are guided by linear slide rails.

7. Folding wheels are made of tool steel, offering excellent wear resistance.

The cutting knife and fixture operating speeds, as well as the edge‑heating temperature, are all adjustable.

Ⅵ. Technical Parameters

Category |

Technical Specification |

Parameter/Requirement |

Applicable Cell Dimensions |

Length |

20 mm – 375 mm |

Width |

15 mm – 155 mm |

|

Thickness |

5 mm – 15 mm |

|

Environmental Conditions |

Ambient Temperature |

10 ℃ – 40 ℃ |

Relative Humidity |

20 % – 90 % |

|

Air Supply |

Non-corrosive gas/liquid, no explosive gases |

|

Equipment Precision |

Overall Precision |

± 0.05 mm |

Trimming Accuracy |

± 0.2 mm |

|

Efficiency |

Single Cycle Time |

6 – 8 seconds |

Overall Efficiency |

Dependent on manual loading/unloading speed and quantity per load |

|

Fixture |

Effective Length |

375 mm |

Pass Rate |

Machine Pass Rate |

≥ 98 % (excluding incoming material issues and operator error) |

Folding/Heating Requirements |

Double-Fold |

Edges must not extend beyond the cell body; folding and heating are completed in one step |

Ⅶ. Consumables Configuration

One set of cutting knives is provided, and one set of hex wrenches is included.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588