products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

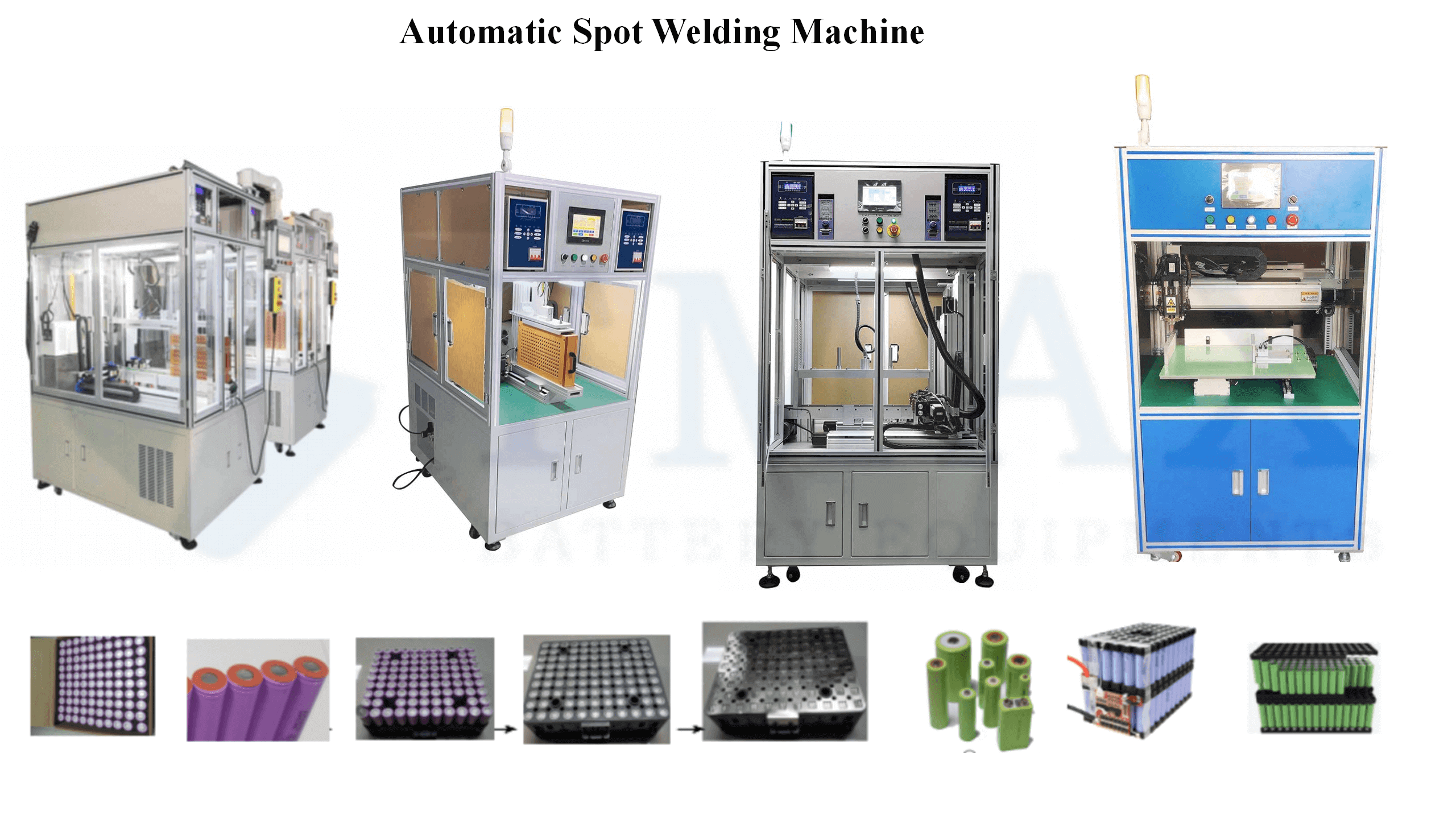

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

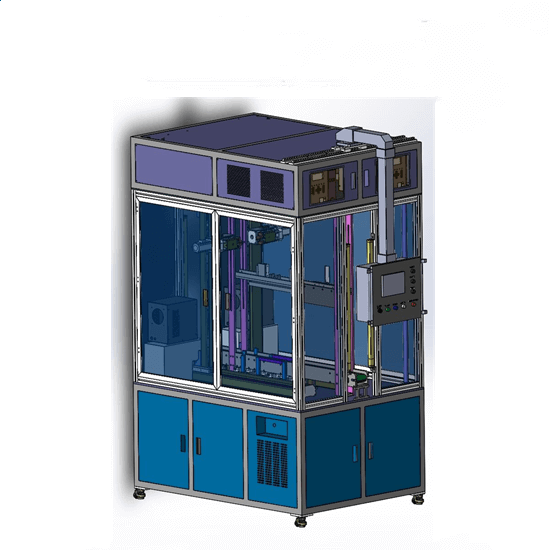

5000A/8000A Welding Power Supply Full-automatic Pipeline Double Sides Spot Welding Machine for Battery Pack Assembly Line

Model Number:

Tmax-ABW-70425Type:

AutomaticInput Power:

4000WDimension(L*W*H):

1850*1100*2490mmNet Weight:

650kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5000A/8000A DC inverter Manual Gantry Spot welderNext:

Durable Spot Welding Rods Alumina Brass Welding Needles For Spot Welder

5000A/8000A Welding Power Supply Full-automatic Pipeline Double Sides Spot Welding Machine for Battery Pack Assembly Line

Tmax-ABW-70425

Advantages:

1.The double-sided automatic spot welding machine supports breakpoint start, and can be equipped with transistor welding power supply and 5000A / 8000A inverter DC welding power supply. It can weld slotted nickel sheets below 0.3mm.

2.Double sided automatic welding, high efficiency.

3.The programming interface is easy to operate. It supports CAD array and manual programming. Any point programming and array programming can store any group of programming files.

4.Warning for welding electrode replacement.

5.The welding head adopts air-cooled or water-cooled circulating heat dissipation to effectively reduce the loss of welding needle and improve the welding effect:

6.If the spot welding machine is equipped with 8000A inverter DC and transistor welding power supply, the machine is equipped with welding current monitoring system, which now monitors the welding current and manages the false welding alarm function. When the industrial computer is used to control the welding real-time monitoring equipment, the welding parameters and abnormal welding point identification can be collected and displayed on the display screen; The welding results can be collected through communication. All welding parameters can be traced to facilitate data management. It has the functions of fire explosion, false welding, false welding, monitoring and recording.

7.The machine can be equipped with rotary welding head, which is not easy to stick the welding electrode. It is also suitable for the welding of special-shaped battery pack.

8.Electric model of machine can effectively prevent false welding and explosion welding caused by unstable air pressure.

9.Welding pressure: the pressure of two welding electrodes is adjusted independently, with the functions of counting the number of times of use of welding electrodes, alarming and clearing.

10.Machine has the functions of origin reset and breakpoint continuous welding, that is, in case of shutdown caused by abnormal problems in the process of spot welding, you can choose to return to the origin or continue welding from the breakpoint, with the function of regional repair welding.

Specification

Motor |

Fully Imported Servo Motor |

Travel length |

6-axis double Y, 700*700mm |

Welding power supply |

5000A/8000A DC Welding Power Supply Transistor welding power supply |

Y-axis stroke |

700mm (customizable) |

Z-axis stroke

|

700mm (double) (customizable) |

Maximum spot welding speed |

0.5s/point (about 3500nos 18650 cells)

|

Motor transmission speed |

1000mm / S |

Maximum number of loaded cells |

Y direction: 34; Z direction: 34 |

Number of file groups that can be stored |

100 groups |

Operating system |

Embedded system man-machine interface |

Transmission mode |

Taiwan precision screw and guide rail |

Driving mode |

400W servo motor |

Repeated positioning accuracy |

± 0.02mm |

Overall dimensions |

L 1850, W: 1100, H: 2490mm |

Overall power |

4000W |

Overall weight |

650kg |

Maximum bearing weight of y-axis |

50kg |

Input power supply |

Single-phase AC 220V 51hz / three-phase 380V 50Hz |

Air source |

0.4-0.6mpa |

Touch screen |

Cantilever 10 inch screen |

Current detection |

external current tester |

Gratings |

Front and rear grating protection |

Feeding mode |

Online pipeline transmission (forward and backward & forward and backward) |

Ejection system |

Support the return of emergency braking fixture |

Handwheel positioning |

With handwheel positioning |

Upper computer system |

Optional |

MES system |

Optional |

Code scanning function |

Optional |

![]()

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com