products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

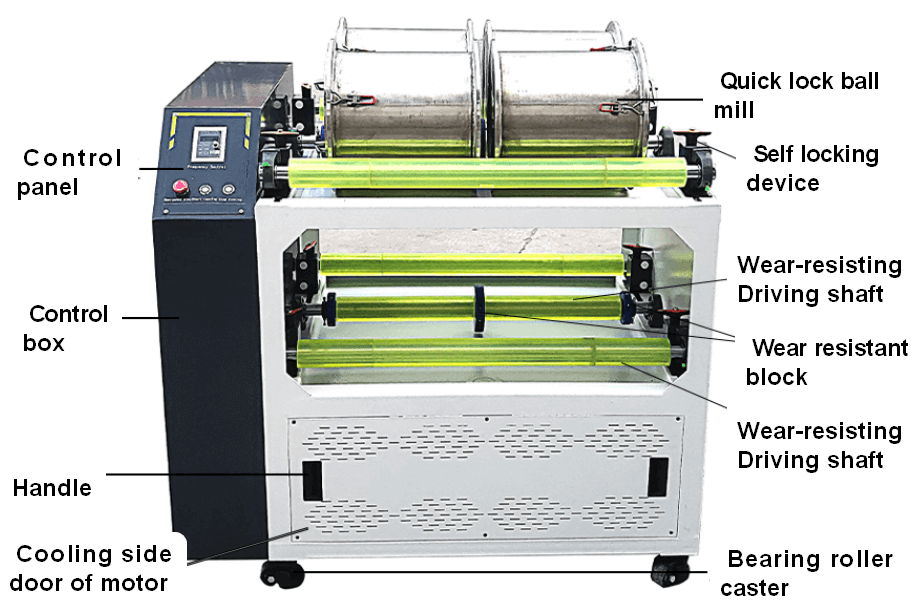

8 Working Stations Jar Mill Ball Mill for Small Batch Material Grinding

Model Number:

TMAX-PM-8-5Dimension(L*W*H):

960*670*960mmNet Weight:

35KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Horizontal Planetary Ball Mill for Powder MakingNext:

High Productivity Horizontal Planetary Ball Mill

8 Working Stations Jar Mill Ball Mill for Small Batch Material Grinding

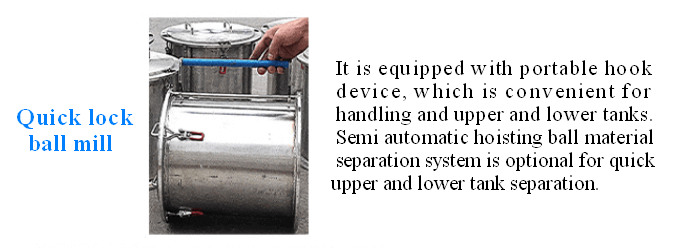

The ball mill of pot mill is driven by a main shaft which is wrapped with wear-resistant rubber parts and connected with the motor pulley through a belt pulley. Relative motion occurs between the outer wear-resistant rubber part on the main shaft and the tank body, that is, friction with the surface of the ball mill pot to drive another driven shaft to realize rolling, The grinding media and materials in the ball mill pot are lifted to a certain height with the rotation of the cylinder body, and are separated from the cylinder wall due to gravity and fall along a parabola. The materials are crushed under the impact of the grinding medium and the friction and shear caused by the rolling and sliding of the grinding medium. The equipment has novel appearance design, simple structure and convenient use.

Application:

The ball mill of pot mill is driven by a main shaft which is wrapped with wear-resistant rubber parts and connected with the motor pulley through a belt pulley. Relative motion occurs between the outer wear-resistant rubber part on the main shaft and the tank body, that is, friction with the surface of the ball mill pot to drive another driven shaft to realize rolling, The grinding media and materials in the ball mill pot are lifted to a certain height with the rotation of the cylinder body, and are separated from the cylinder wall due to gravity and fall along a parabola. The materials are crushed under the impact of the grinding medium and the friction and shear caused by the rolling and sliding of the grinding medium. The equipment has novel appearance design, simple structure and convenient use.

Features:

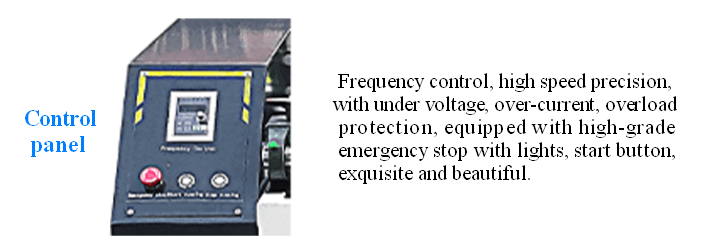

1. It can be used in single or multiple tanks at the same time, and multiple samples can be ground at the same time;

2. It can stop the machine regularly, intermittently or continuously;

3. The wear-resistant rubber parts are coated on the shaft roller, which are made of special materials and are durable;

It is suitable for material fine grinding, crushing, mixing, anti precipitation and other process requirements, with high efficiency;

5. Can be customized according to customer requirements (multi station customization, multi-stage power output customization, etc.); proofing machine.

Specifications:

Name |

PM-8-5 |

PM-8-15 |

Reference dimension (mm) |

960*670*960 |

1130*800*960 |

Weight (kg) |

110KG |

150Kg |

Motor specifications |

Y1.5-4B3 |

Y2.2-4B3 |

Frequency converter specification |

1.5kw/single phase 220V |

2.2kw/three-phase 380V |

Main roller speed (R / min) |

50-450 |

40-420 |

Maximum load of single tank (kg) |

35kg |

80kg |

Hand crank / protective cover |

Matching |

Matching |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com