products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

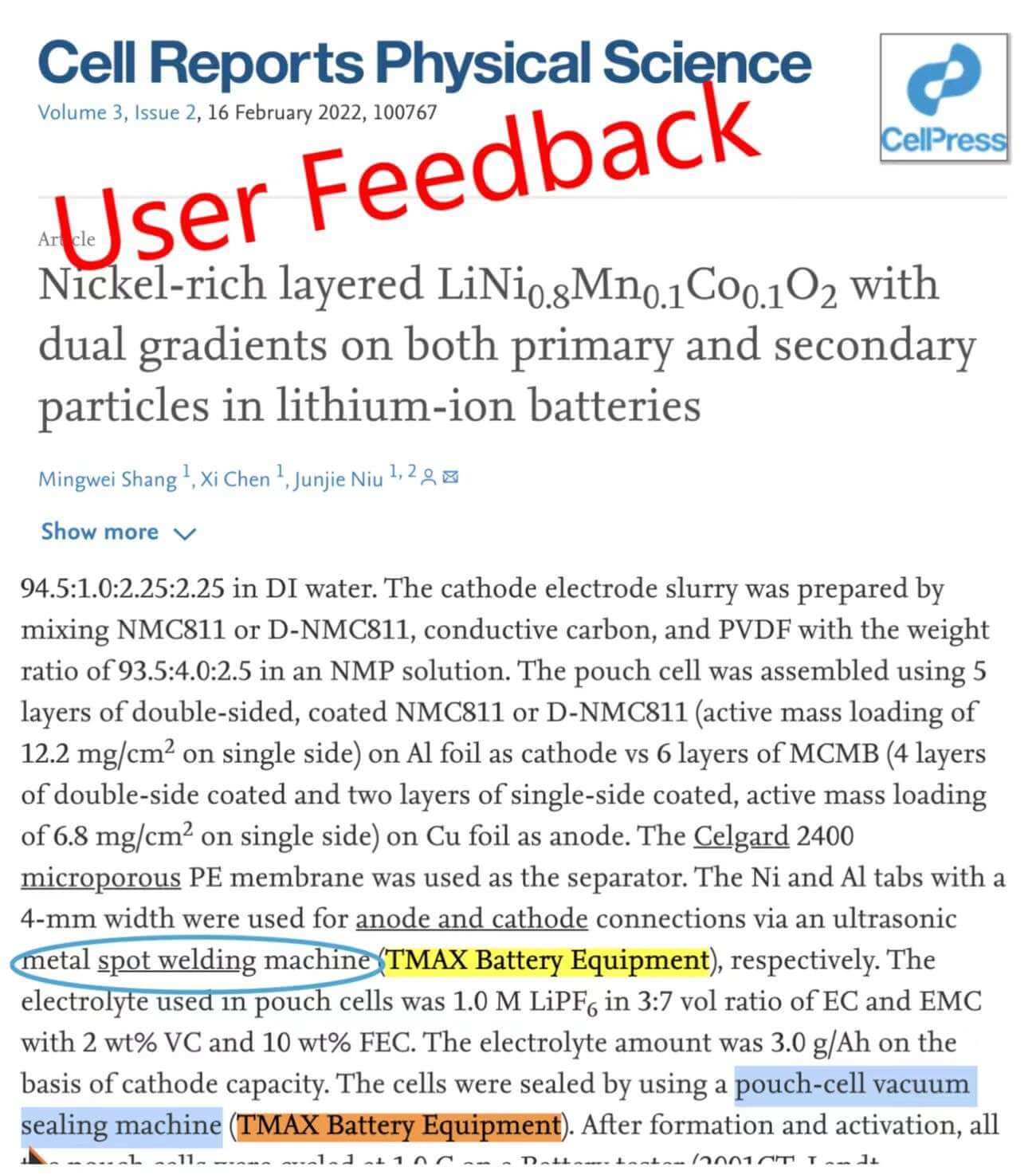

800W Ultrasonic Welder for Solid Cell Production

Model Number:

TMAX-USW-800WInput Power:

800WDimension(L*W*H):

550mm x300mm x550mmNet Weight:

70kgCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

7 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Compact Filtration/Sieving System (750mL) for Electrode SlurryNext:

Laboratory Solid State Battery Semi-Auto Stacking Machine

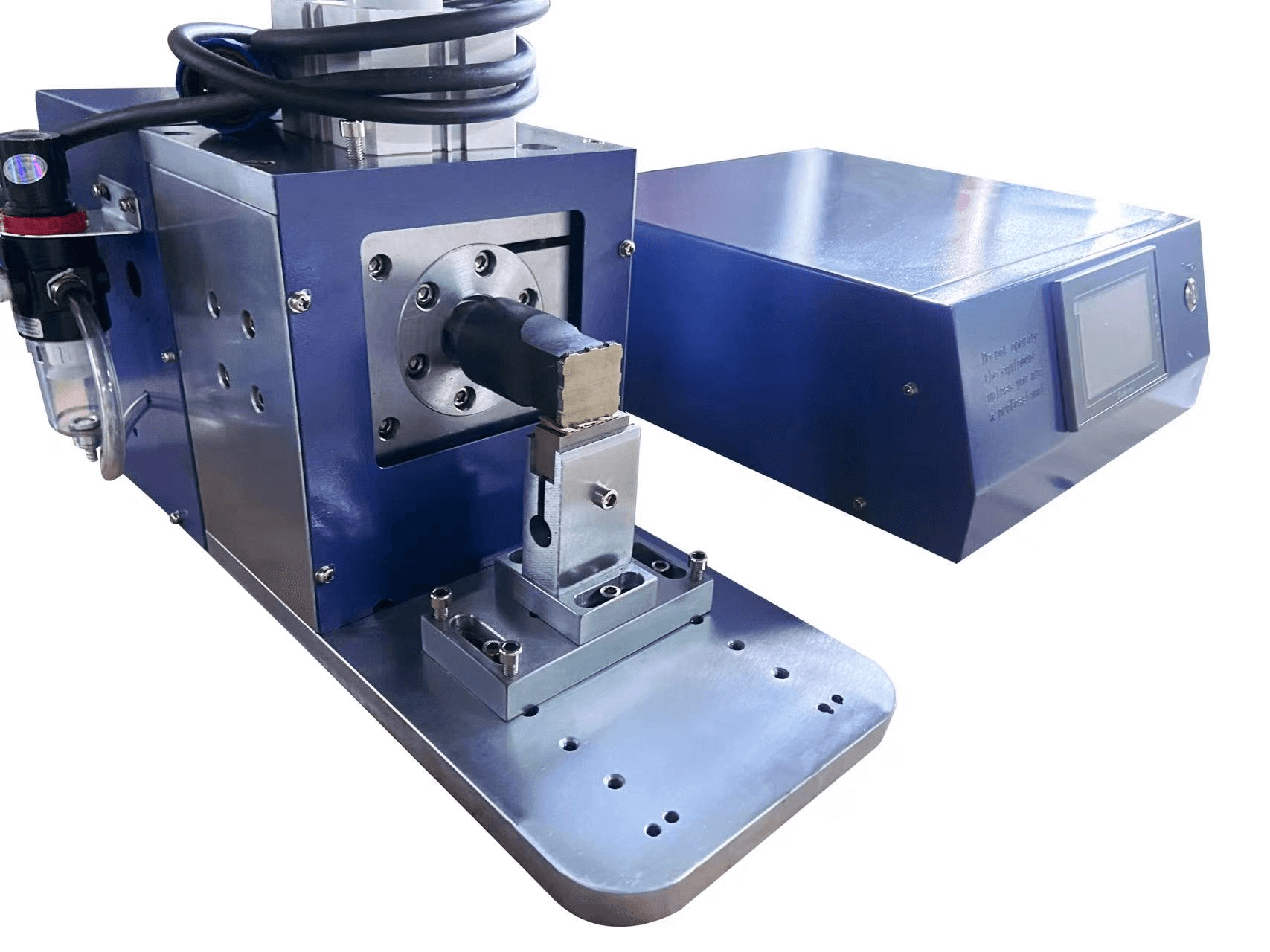

800W Ultrasonic Welder for Solid Cell Production

Using a high-performance anti-interference microprocessor to implement electronic control, the parameters of the welding control are managed by a microcomputer. An intelligent frequency control system eliminates the inconvenience of manual frequency tuning. Sound wave overload is automatically detected, and the system real-time tracks the optimal resonance point, keeping the temperature of the vibrating group at the lowest point. The machine automatically adjusts to frequency

Functional Features

◆ Fully digital ultrasonic system imported from Germany.

◆ The speed of the welding head's ascent and descent can be adjusted for accurate control.

◆ Able to precisely locate the vertical position of the welding structure.

◆ The ultrasonic generator can automatically compensate for output voltage fluctuations to ensure stable amplitude output from the weld head segment.

◆ Accurate energy control can ensure the stability of each weld and reduce the impact of external factors.

◆ The welding head equipment uses automatic frequency chasing, eliminating the need for manual tuning.

◆ Use of IGBT power modules plus self-excited oscillation circuit structures. Over 100 welding records can be queried.

◆ Cloud services can be customized. Intelligent protection for the machine and fault alarm prompts.

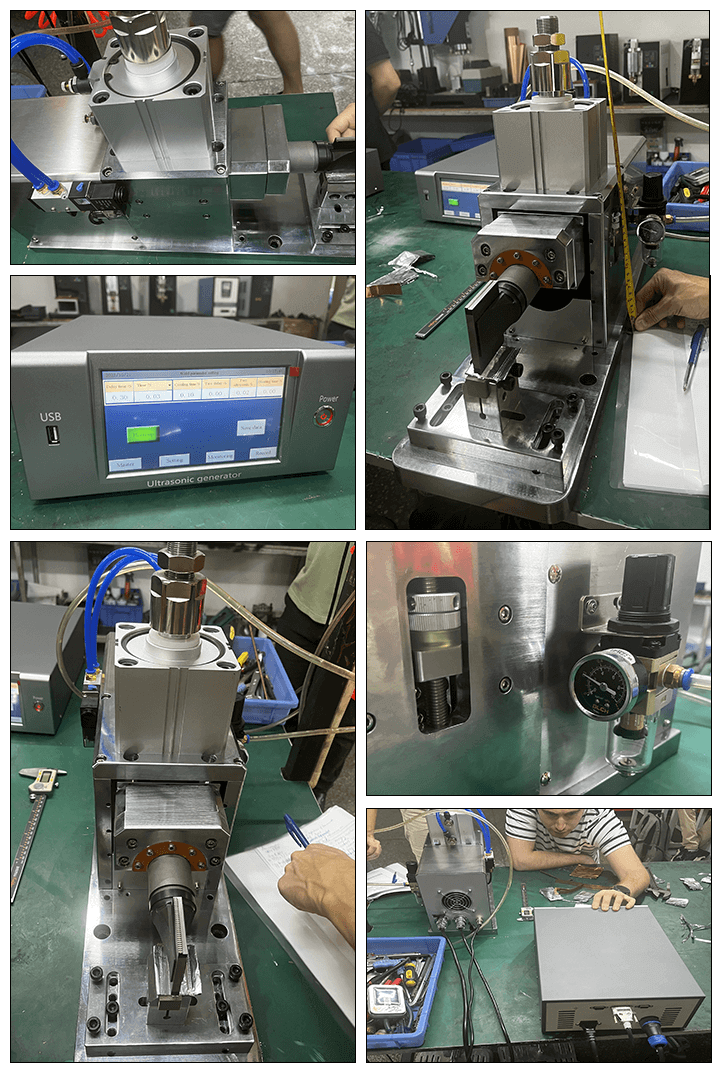

Transducer parameters:

Frequency difference between each transducer ≤ 39.5-40.5Hz

Impedance difference between each transducer ≤ 8Ω

Capacitance difference between each transducer ≤ 40PF

Insulation resistance between transducer and casing ≥ 30MΩ

Frequency control method Built-in adjustable frequency

Equipment design service life 8~10 years

Specification

Feature Category

Feature Details

Power Supply Voltage

50/60Hz-/AC220V

Screen

Touch screen

Digital System

High stability

Frequency

Automatic tracking

Power

800W

Parameter Save Function

Yes

Customizable Welding Parameter Recall

Yes

Welding Head Mode

Single point pneumatic

Welding Time

Adjustable (0.01s-2s)

Pre-pressure Time

Adjustable (0.02s-10s)

Frequency Calculation Display Search Range

39.0000-41.0000HZ

Adjustable Power

500W, 800W

Welding Mode

Selectable

Amplitude Adjustment

Stepless amplitude adjustment

Chassis Protection

Intelligent protection and fault alarm prompts

Automatic Frequency Tracking

Range ±20HZ

Automatic Temperature Tracking

Internal power tube 60° automatic protection

EMI/EMC

Strong anti-interference ability

Input Air Source

Compressed air 7-8BAR (kilograms/square centimeter)

Maximum Working Air Pressure

6 kilograms/square centimeter

Minimum Working Air Pressure

0.3 kilograms/square centimeter

Air Inlet Connector

Quick connector 8mm

Cylinder Diameter

63mm

Cylinder Stroke

20mm

Peripheral Dimensions

About 900mm×600mm×750mm

Total Weight

About 60 kilograms

Packaging Dimensions

About 1000mm×600mm×800mm

Chassis Size

About 360mm×340mm×150mm

Machine Head Size

About 500mm×310mm×320mm

Feature Category |

Feature Details |

Power Supply Voltage |

50/60Hz-/AC220V |

Screen |

Touch screen |

Digital System |

High stability |

Frequency |

Automatic tracking |

Power |

800W |

Parameter Save Function |

Yes |

Customizable Welding Parameter Recall |

Yes |

Welding Head Mode |

Single point pneumatic |

Welding Time |

Adjustable (0.01s-2s) |

Pre-pressure Time |

Adjustable (0.02s-10s) |

Frequency Calculation Display Search Range |

39.0000-41.0000HZ |

Adjustable Power |

500W, 800W |

Welding Mode |

Selectable |

Amplitude Adjustment |

Stepless amplitude adjustment |

Chassis Protection |

Intelligent protection and fault alarm prompts |

Automatic Frequency Tracking |

Range ±20HZ |

Automatic Temperature Tracking |

Internal power tube 60° automatic protection |

EMI/EMC |

Strong anti-interference ability |

Input Air Source |

Compressed air 7-8BAR (kilograms/square centimeter) |

Maximum Working Air Pressure |

6 kilograms/square centimeter |

Minimum Working Air Pressure |

0.3 kilograms/square centimeter |

Air Inlet Connector |

Quick connector 8mm |

Cylinder Diameter |

63mm |

Cylinder Stroke |

20mm |

Peripheral Dimensions |

About 900mm×600mm×750mm |

Total Weight |

About 60 kilograms |

Packaging Dimensions |

About 1000mm×600mm×800mm |

Chassis Size |

About 360mm×340mm×150mm |

Machine Head Size |

About 500mm×310mm×320mm |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016