products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Compact Filtration/Sieving System (750mL) for Electrode Slurry

Compact Filtration/Sieving System (750mL) for Electrode Slurry

Compact Filtration/Sieving System (750mL) for Electrode Slurry

-

512 Channel 5V 6A Lithium Battery Capacity Analyzer

512 Channel 5V 6A Lithium Battery Capacity Analyzer

-

Automatic loading Lithium Battery Protection Board Testing Machine

Automatic loading Lithium Battery Protection Board Testing Machine

-

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

Precision Automatic Winder for Electrode Assembly of Cylindrical Battery TMAX-YS-BYZ65 is an automatic winding machine for accurate assembly of cylindrical battery electrode cores (also known as “jelly roll”). Using this machine, cathode and anode films, separated by top and bottom separator films, are rolled up into a hollow cylinder casing for cylindrical battery applications. It is an ideal tool for reliable and precise production of high quality windings of electrode cores.

-

Semi-Auto Cylindrical Cell Winding Machine for 33140 Cell

Semi-Auto Cylindrical Cell Winding Machine for 33140 Cell

Semi-Auto Cylindrical Cell Winding Machine for 33140 Cell Ⅰ、Device Function Description: This machine is mainly used for precision winding of cylindrical lithium-ion battery cells. The working process is as follows: manually guide the positive and negative plates into the winding part, separate them from the diaphragm, and roll them according to the process requirements. The termination tape is automatically attached, and the battery cells are automatically cut off. Ⅱ、Equipment functions and characteristics 1、 Adopting a single needle structure for threading and rolling. 2、Manual introduction of electrodes, automatic winding, automatic needle changing, automatic application of termination tape, and automatic cutting; 3、The adhesive tape is applied horizontally (with the termination tape perpendicular to the tab), ensuring a smooth and precise control of the adhesive position without pulling the battery cell tightly; Stable and reliable adhesive application; 4、The needle winding speed is adjustable; 5、Active unwinding of two separators, tension proximity switch control technology, can automatically and smoothly adjust tension during the winding process; 6、Equipped with a electrode dust removal device 7、Separator outsourcing closure; 8、The rolled out battery cells are free from damage, core pulling, and electrode misalignment. 9、 Easy to operate, simple and fast to adjust and replace specifications; Ⅲ、 Process flow This device meets the process standards for winding cylindrical lithium-ion batteries: the separator completely wraps around the negative electrode, and the negative electrode wraps around the positive electrode. The process flow is as follows: 1、Separator pre winding: The use of toothed knife technology can save the length of pre winding separator; 2、Entangled negative electrode: manually guide the negative electrode into the winding part; Entangled positive electrode: manually guide the positive electrode plate into the winding part; 3、Winding; 4、Moving workstations; 5、Cut off the separator, apply termination adhesive, and cut off the material. Ⅳ、The main components of the equipment 1、This equipment consists of a winding device, a changing station device, a separator unwinding device, a electrode guide device, a tape sticking device, a cutting device, and a control system. 2、 Winding device (two sets): composed of single end threading, ensuring winding accuracy and convenient replacement of winding needles; 3、 Shift station device (one set): used for switching between winding station and adhesive station; 4、 Separator unwinding device (two sets): diaphragm material roll actively unwinding air pressure regulation control; 5、 Electrode guide device (two sets): single-sided adjustment, easy to adjust; 6、 Gluing and cutting device (one set). Ⅴ、Technical standard 1、Separator width:50-140mm winding needle specification:∮3.0-∮12mm,,customize according to customer’s requirement ,electrode width:48-137mm 2、Material specification requirements (unit: mm) 3、Applicable cell outer diameter(∮8-∮33mm) 4、Winding accuracy; When ensuring that the electrode meets the following conditions: The width error of the electrode is less than ± 0.2mm; The "S" bending error of the electrode is less than ± 1mm/500mm; The tower shape error of the separator material roll is less than ± 0.2mm; The winding accuracy can meet the following requirements: the alignment error of the separator is less than ± 0.5mm; The alignment error of the electrode is less than ± 0.5mm; Can achieve an alignment of ± 0.5mm between the negative electrode and the positive electrode, as well as the separator and the negative electrode 5、 Qualification rate: ≥ 98% (excluding non equipment factors) Ⅵ、Technical standard Specification Remark Basic Specification Input Power AC220V,1.5KVA,50HZ Compressed air 0.4-0.6MPa Weight About 500kg Size 1750mm*1350mm*1570mm (L*W*H) Based on actual design Excluding the extended length of the electrode slot, unit::mm Winding needle specification ∮3.0mm-∮12mm Delivery of one set according to customer requirements Mechanical Specification Rack and mounting plate 1set Winding needle mechanism 1set Electrode supply mechanism 2set Separator Supply mechanism 2set Tape pasting mechanism 1set Control System Specification PLC PANASONIC AFRX-C60T Touch screen Weilang Winding motor Zhengyuan Tension motor Stepper motor Li San/Zheng Yuan Sensor Ailifu/Daochuan Pneumatic parts Yadeke/Xingchen Alarm System Fault stop Fault prompt Program built-in One click reset Accessories Operation manual 1 set of operation manual Spare parts 1set See delivery list

-

Prismatic Lithium Battery Cell Stacking and Pressing Machine

Prismatic Lithium Battery Cell Stacking and Pressing Machine

-

Sodium Ion Battery Manual Winding Machine

Sodium Ion Battery Manual Winding Machine

-

80L Small Temperature Humidity Test Chamber Environmental&Climatic Tester

80L Small Temperature Humidity Test Chamber Environmental&Climatic Tester

-

AG3(LR41) Coin Cell Case for Coin Cell Research

AG3(LR41) Coin Cell Case for Coin Cell Research

-

30L Planetary Dispersion Vacuum Mixer for Electrode Preparation

30L Planetary Dispersion Vacuum Mixer for Electrode Preparation

30L Planetary Dispersion Vacuum Mixer for Electrode Preparation Ⅰ、 Equipment features: Scope of application: The powder and liquid of all kinds of common batteries are mixed and dispersed to finally get a evenly mixed battery slurry. It is very suitable for high viscosity process. The applicable working condition viscosity range is ≤ 1.2 million CP. Ⅱ、 Main parameters of equipment: Lower barrel part: Total design volume: 45L Effective volume: 15-30L Internal diameter of container: 400mm Internal depth of container: 360mm Container material: contact part with materials 304 Temperature regulating jacket form: single-layer jacket on barrel wall for cooling or heating; Single layer jacket at barrel bottom for cooling or heating Temperature regulating jacket interface: G1/2 ", equipped with quick opening Union, jacket pressure resistance ≤ 0.4MPa Temperature regulating jacket circulating system: provided by the customer. It is recommended that the jacket inlet temperature ≤ 8 ℃, and the cooling water flow > 15L/min Discharge form: a G1 "3 pcs discharge ball valve at the bottom of the barrel Design ambient temperature: -10 ~ +120 ° C Movement mode: caster Mobile Mixing parts: Working frequency: 5-50Hz Mixing power: 4KW Mixing paddle speed: 6-64rpm Planetary case speed: 4-42rpm Diameter of mixing paddle: 218mm Mixing paddle style: variable cross-section spiral fried dough twist type, 90 ° spiral Mixing paddle material: 304 Linear speed of mixing paddle: 0.09-0.9m/S Number of mixing paddles: 2 Paddle to paddle distance:7 ± 2mm Distance between paddle and barrel wall: 4 ± 1mm Distance between paddle and barrel bottom: 3 ± 1mm Dispersed parts: Working frequency: 5-50Hz Distributed power: 4KW Dispersive speed:402-4020rpm Diameter of dispersion plate: 110mm Style of dispersion disk: zigzag Material of dispersion plate: 304 Linear speed of dispersion: 2.3 -23m/s Number of distributed disks: 2 Number of dispersion shafts: 1 Wall scraping parts: wall scraping support material: 304 Material of wall scraping plate: polytetrafluoroethylene Wall scraping speed: consistent with planetary case speed Whether it is detachable: detachable design (the wall scraping must be removed during high viscosity process) Base and lifting parts: Component material: carbon steel for high rigid structure Lifting method: electric lifting Lifting guide: high precision linear guide rail Lifting stroke: ≤ 500mm Upper barrel part: Upper barrel material: 304 Powder feeding port: quick opening interface DN75 Liquid feeding port: one ISO standard 1 "quick connector Spotlight port: one DN70 tempered glass mirror "Vacuum pumping port: G 3/4" 1pc Exhaust port: G1/2":1pc Digital vacuum gauge port: M14 × 1.5 one internal metric tooth interface Control system: Electrical cabinet: used to place low-voltage electrical components such as frequency converter Manual operation panel: used to place buttons, knobs, instruments, etc Power supply: AC 3 × 380V±5﹪,50Hz Control mode: electric control + hydraulic control Power control and speed regulation mode: frequency converter startup and control Cooling method: air cooling and liquid cooling Operation mode: corresponding buttons + knobs on the upper panel of the electric cabinet Digital temperature display table: material temperature Emergency stop button: one Alarm system: over temperature alarm, over temperature alarm shutdown, alarm shutdown Speed display: the panel table displays the speed Power indicator: one Timer: one to control dispersion and mixing at the same time Attention: if the man-machine interface system configuration is selected, relevant contents of the control system will be integrated into the touch screen for control Safety interlock system: Emergency stop: press the emergency stop switch and the equipment will stop immediately without any operation Start low-speed mixing: it can turn while lifting the barrel High speed dispersion: the barrel can be rotated only after it is raised to the right place Safety lock during operation: when the machine is running to mix materials, the mixing drum cannot be lowered or opened. To prevent the vacuum pipeline from flowing back: the special vacuum buffer tank design can effectively prevent the vacuum pump oil from flowing back to the mixing tank Operation fault stop: the frequency converter is equipped with overload, overcurrent, overvoltage, leakage and lack of equal protection. Lifting and lowering of mixing barrel: the mixing barrel can not be lifted until it is in place. The mixing drum cannot be lowered without vacuum discharge (normal pressure is not restored). The high-speed dispersion can only be started after the mixing drum is lifted in place. After the mixing drum is lifted in place, it is equipped with a locking protection system to prevent the drum from falling abnormally after it rises to the high position during operation. In the dry mixing stage, the mixing paddle needs to rotate while lifting the bucket. Other instructions: Temperature measuring probe: PT100 Temperature measurement method: the barrel wall is equipped with a temperature measuring head to detect the material temperature Bearings of transmission parts: high-speed parts are imported bearings, and low-speed parts are domestic bearings Oil seal: domestic brand, O-ring for static seal and mechanical seal for dynamic seal Lubricating grease: domestic brand Mechanical seal lubricating oil: imported brand Oil cylinder: domestic brand Service station: domestic brand Valves: domestic brands Vacuum design demand: customers must provide their own vacuum system with 4L/S (2X-4) "Vacuum maintaining: -0.098mpa, pressure maintaining higher than -0.085mpa for 24 hours, no leakage into the barrel" Total host power: > 8KW Overall weight: about 1400kg Equipment size: 1650mm L*W 760mm * 1899mm H Appearance color: beige Ground bearing capacity: 1000kg/ ㎡ Ⅲ、 Supporting conditions: No. entry name Standard requirements 1. Workshop height >3M ; The lifting and lowering of the machine requires a certain height guarantee and consideration of maintenance needs; Clean and level. 2. Door size Height: > 2.5m; Width: > 1.5m; To ensure that the machine is transported in and out. 3. cooling water To ensure the cooling requirements, it is better to have a forced cooling water supply system; If thermal insulation is required in winter, hot water supply is required. 4. Heating In view of the cold weather in the north in winter, in order to prevent the hydraulic oil for lifting from condensation, it is necessary to ensure that the indoor temperature is > 20 º C to ensure the smooth lifting of the machine; And ensure the normal operation of the lubrication system. 5. Installation space Refer to the general plan of the scheme for layout. 6. Gas source 5~7 kgf/cm ², 100 L/min; Pneumatic pump drive and other occasions. 7. other No corrosive gas, liquid and explosive gas.

-

Laboratory Intermittent Coating Machine with Winding and Unwinding System

Laboratory Intermittent Coating Machine with Winding and Unwinding System

-

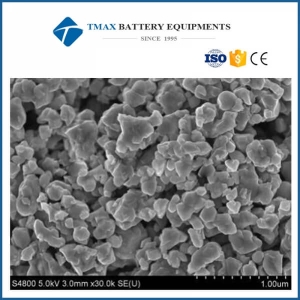

Lithium Titanate Powder LTO For Li-ion Battery Cathode Materials

Lithium Titanate Powder LTO For Li-ion Battery Cathode Materials

LTO/ Lithium titanate/Lithium Titanium Oxide/ LiTiO / Li4Ti5O12(Carbon coating is black powder, no carbon coating is white powder). At present, it is mainly used in energy storage battery, EV battery, special power supply, super capacitor and so on. 1. Advantage: High safety, long service life, high power. 2. Shortcoming: Low energy density. 3. Application: Anode materials for lithium ion batteries.

-

LiFePO4 Powder Raw Materials For Lithium ion Battery Producing

LiFePO4 Powder Raw Materials For Lithium ion Battery Producing

Specification Main application: Is the positive active material of the power battery. Mainly used for energy storage/electric tools/light electric vehicle/miner's lamp/mobile power and so on. Main characteristics: 1. High energy density, Its theoretical specific capacity is 170 mAh/g, Actual product specific capacity can be more than 140 mAh/g (0.2 C, 25 ° C); 2. High security, is the safety of lithium ion battery cathode material; Do not contain any harmful heavy metals; 3. long life: In 100% DOD (depth of discharge) conditions, can charge and discharge more than 2000 times;(reason: lithium iron phosphate lattice stability is good, the lithium ions embedded and emergence of lattice impact is not big, so it has good reversibility. The deficiencies are ionic conductivity electrode is poor, not suitable for large current charge and discharge, stuck in applications. Solution: in the electrode coating on the surface of conductive material, doped modified electrode. ) The service life of the lithium iron phosphate battery with temperature, temperature too low or too high in the charging and discharging process and use process produce greatly bad hidden trouble. Electric cars use especially in northern China, in the fall and winter normal power supply of the lithium iron phosphate batteries or power supply is too low, need to adjust its working environment temperature to maintain its performance. At present, the domestic solve the lithium iron phosphate battery temperature working environment should be considered space limitations, the common solution is to use the aerogel blanket as a thermal insulation layer.

-

LiFePO4 Powder for Power Battery Material

LiFePO4 Powder for Power Battery Material

SpecificationSpecification It is positive electrode active material of the lithium ion battery. The nickel cobalt manganese three yuan battery material as positive pole of battery are more safety than lithium cobalt oxide battery.Mainly used for small electric equipment. Main application: Is the positive active material of the power battery. Mainly used for energy storage/electric tools/light electric vehicle/miner's lamp/mobile power and so on. Main characteristics: 1. High energy density, Its theoretical specific capacity is 170 mAh/g, Actual product specific capacity can be more than 140 mAh/g (0.2 C, 25 ° C); 2. High security, is the safety of lithium ion battery cathode material; Do not contain any harmful heavy metals; 3. long life: In 100% DOD (depth of discharge) conditions, can charge and discharge more than 2000 times;(reason: lithium iron phosphate lattice stability is good, the lithium ions embedded and emergence of lattice impact is not big, so it has good reversibility. The deficiencies are ionic conductivity electrode is poor, not suitable for large current charge and discharge, stuck in applications. Solution: in the electrode coating on the surface of conductive material, doped modified electrode. ) The service life of the lithium iron phosphate battery with temperature, temperature too low or too high in the charging and discharging process and use process produce greatly bad hidden trouble. Electric cars use especially in northern China, in the fall and winter normal power supply of the lithium iron phosphate batteries or power supply is too low, need to adjust its working environment temperature to maintain its performance. At present, the domestic solve the lithium iron phosphate battery temperature working environment should be considered space limitations, the common solution is to use the aerogel blanket as a thermal insulation layer.

-

Surface Area and Pore Size Analyzer

Surface Area and Pore Size Analyzer

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016