products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Air-cooling control within 0-15 ℃ planetary ball mill

Model Number:

TMAX-Mill-1Input Power:

1.5KWDimension(L*W*H):

800*1200*1000 mmNet Weight:

110KGCompliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

High Efficiency Cryogenic Grinding MillNext:

4L Nano Scale Horizontal Planetary Ball Mill Machine

Air-cooling control within 0-15 ℃ planetary ball mill

Cryogenic planetary laboratory

ball milling is composed of planetary ball mill and refrigeration device. Most

of materials are heating-up because of friction and exothermal reaction in

process of grinding at high speed, which may cause changing of chemical and

physical properties of materials and lead to negative effect of grinding.

Cryogenic planetary lab ball milling is mainly used for grinding materials

which need to control their temperature.

Application Field

The product is extensively applied in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

It's widely used in research institutes, universities, enterprise laboratories and small batch producing manufacturer.

Grinding Materials

Electronic ceramics, structural ceramics, magnetic materials, LCO, LMO, catalyst, fluorescent powder,

E-glass powder, fuel cell, zinc oxide varistor, piezoelectric ceramics, nano materials, MLCC, PTC, NTC, media ceramics, fluorescent powder etc.

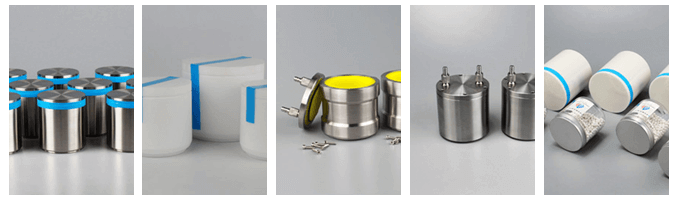

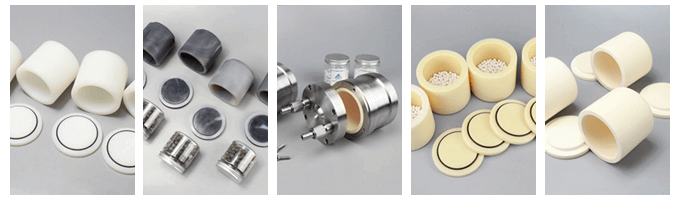

Performance of cryogenic mill grinder

Transmission

Mode

|

Gear Drive |

Working Mode |

2 or 4

pots can be used each time |

Max Volume of

Load |

Two-thirds of pot's volume |

Volume of

Grinding Pot |

0.05L/pot-50L/pot Total Volume: 0.2L-200L |

Feed Size |

Soft and

crispy material ≤10mm, Other materials ≤3mm |

Out-put Granularity |

Minimum

granularity can be reached to 0.1μm |

Adjusting Mode

of Rotate Speed |

Frequency

converter with stepless speed reglulation |

Specification

Type |

Total

Volume of 4 Pots(L) |

Max

Rotate Speed(rpm) |

Power (KW) |

Dimension

(mm) |

Mill-1 |

1 |

670 |

0.75 |

770*470*570 |

Mill-2 |

2 |

670 |

0.75 |

770*470*570 |

Mill-4 |

4 |

670 |

0.75 |

770*470*570 |

Mill-6 |

6 |

670 |

0.75 |

770*470*570 |

Mill-8 |

8 |

670 |

1.5 |

900*600*640 |

Mill-10 |

10 |

580 |

1.5 |

900*600*640 |

Mill-12 |

12 |

580 |

1.5 |

900*600*640 |

Mill-20 |

20 |

430 |

4 |

1200*760*920 |

Mill-40 |

40 |

390 |

5.5 |

1400*850*1030 |

Mill-60 |

60 |

260 |

7.5 |

1600*950*1120 |

Mill-100 |

100 |

240 |

11 |

1750*1100*1180 |

Mill-200 |

200 |

190 |

18.5 |

1920*1400*1350 |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com