products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

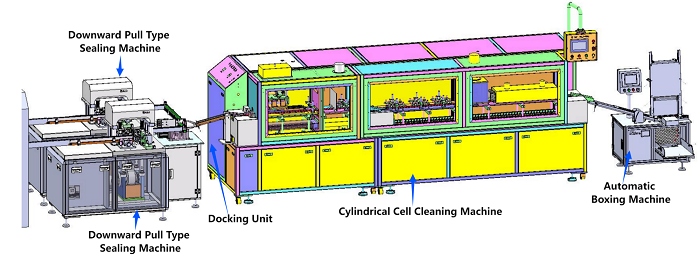

Automatic 2 in 1 Cylindrical Cell Crimping and Cleaning Machine for Lithium-ion Battery

Model Number:

TMAX-ZDQX-18Net Weight:

800lbsCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic 18650 Lithium-ion Cylindrical Cell Shell Insertion MachineNext:

Automatic 4680 Cylindrical Battery Hydraulic Sealing Crimping Machine

Automatic 2 in 1 Cylindrical Cell Crimping and Cleaning Machine for Lithium-ion Battery

1. Overview

- Application: Fully automated sealing and cleaning process for cylindrical lithium-ion batteries post electrolyte filling.

- Integration: Compatible with downstream connection to boxing machines, coding machines, or sleeving machines.

- Automation: No manual involvement from sealing to cleaning.

- Capacity: >100 PCS/min - Operation Time: 8 hours continuous per day

- Personnel Required: 1 operator (for boxing/unloading) - Power Supply: 380V - Suitable Battery Type: 18650 steel casing

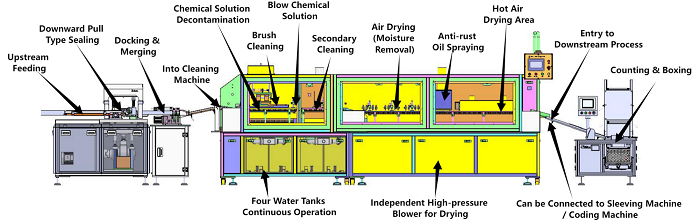

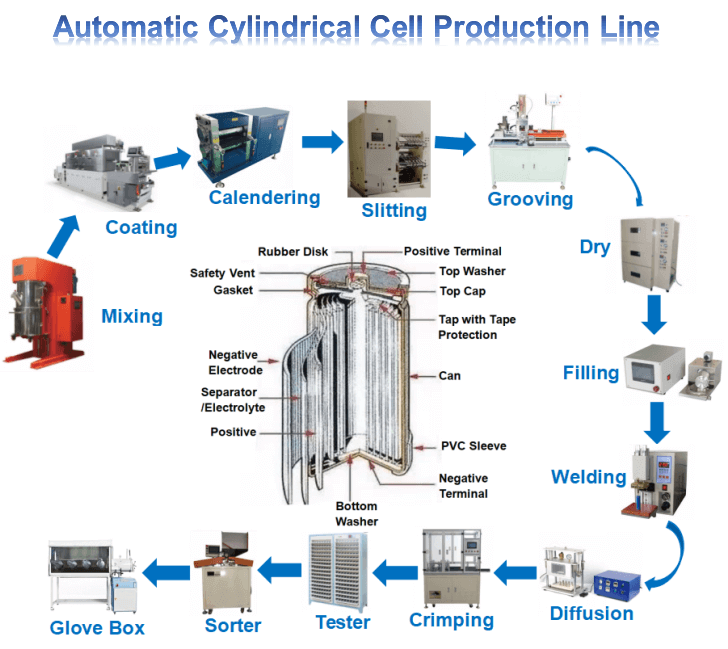

2. Production Line Process Flow

3.

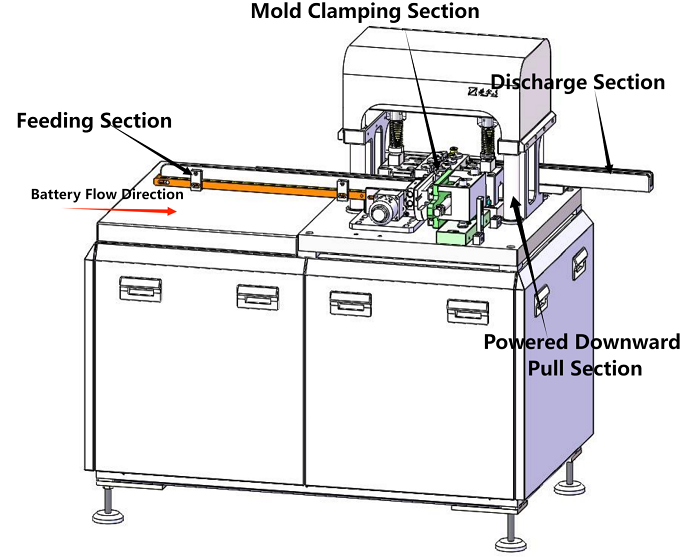

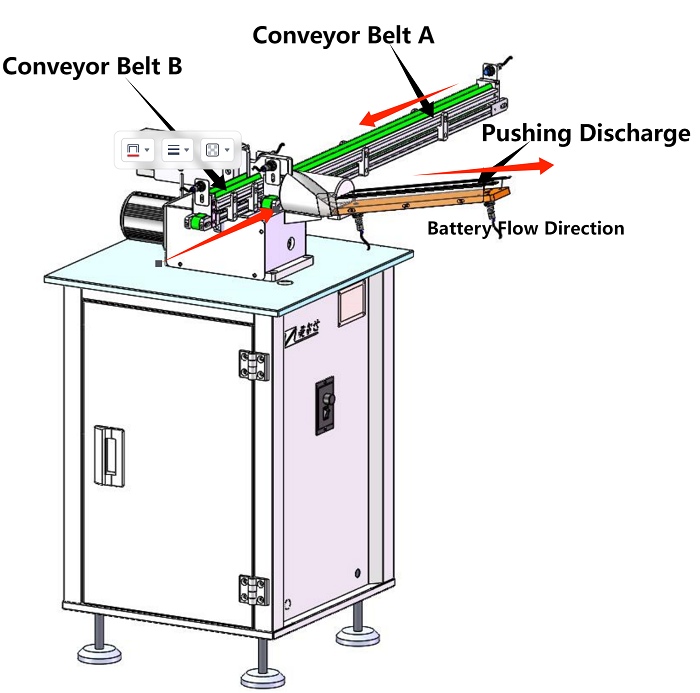

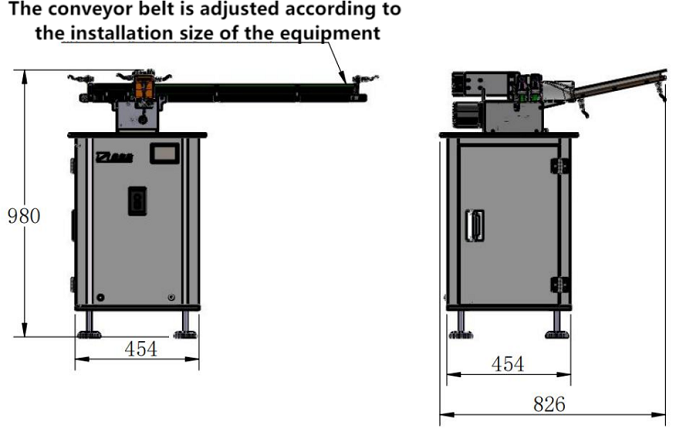

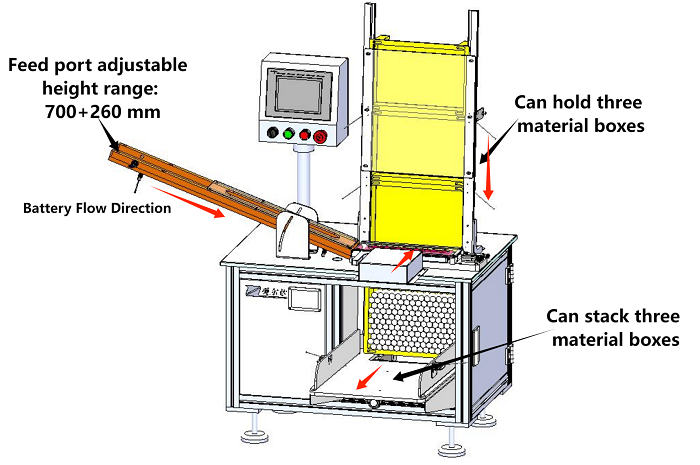

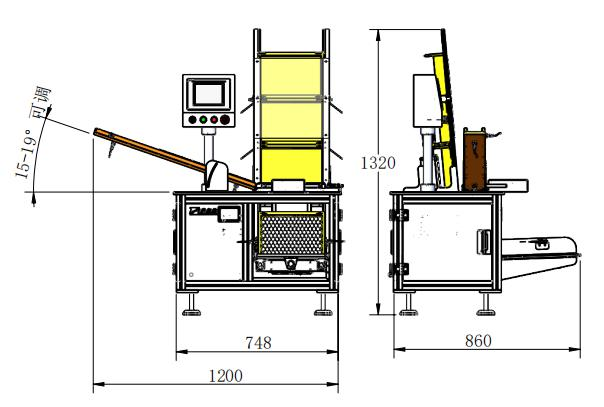

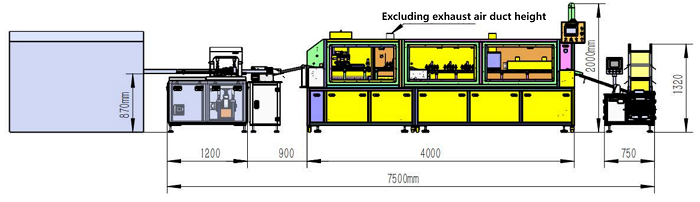

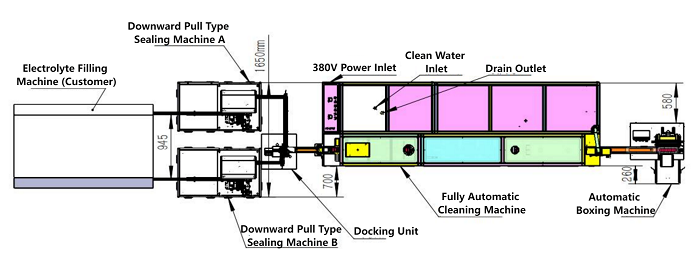

Equipment Layout Diagram

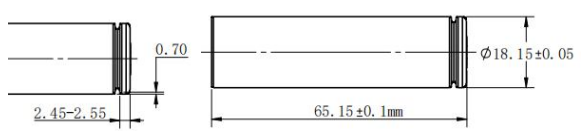

3. Sealing Process Parameters

Sealing Process Dimensions

Item |

Dimension |

Tolerance |

Item |

Dimension |

Tolerance |

Cathode moisture content PPM |

≤200 |

— |

Cathode moisture content PPM |

≤350 |

— |

Electrolyte injection amount (g) ★ |

5.75 |

— |

Total sealing height (mm) |

65.15 |

— |

Sealing end height (mm) |

2.5 |

±0.2 |

Riveted sealing head outer diameter (mm) |

18.35 |

— |

Sealing outer diameter (mm) |

18.35 |

±0.05 |

Holding time (min) |

1 |

Airtightness |

Holding pressure (MPa) |

1 |

— |

Cap burst pressure (MPa) |

1.9–2.5 |

Airtightness |

Cap separation pressure (MPa) |

0.9–1.4 |

— |

Battery weight (g) |

43–44.5 |

— |

Notes:

Airtightness must be tested — Take 3 PCS sealed shell spaces and pressurize on the testing machine; maintain at ≥1 MPa for 1 minute; no gas leakage on the four sealing walls is considered qualified.

For each shift, randomly inspect one cell by disassembly and confirm that the cover plate deformation is ≤0.3 mm.

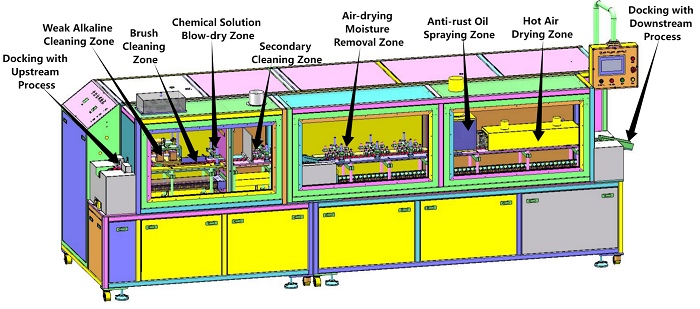

4. Cleaning Process Parameters

Process Stage |

Specification |

Tank 1 / 65 L |

40°C, 90% deionized water + 1100±50 g sodium nitrite, pH 9–11 |

Tank 2 / 65 L |

Same as above |

Tank 3 / 65 L |

Same as above – continuous operation for 4 hours, water must be replaced and cleaned; during cleaning, Tanks 2 & 4 remain operational without stopping the line |

Tank 4 / 65 L |

Same as above |

Oil Spraying |

14 L tank, 0.8 mm nozzle, full-body anti-rust coating |

Hot Air Drying |

Temperature: 70°C, surface clean, no water, no electrolyte residue, uniform oil film; conveyor chain cleaned twice per shift |

Boxing |

Alcohol wiping → Anti-rust oil application on both ends → Cathode-down placement → Plastic film wrapping; film sleeving & coding within 24 hours after cleaning |

5. Equipment Specifications

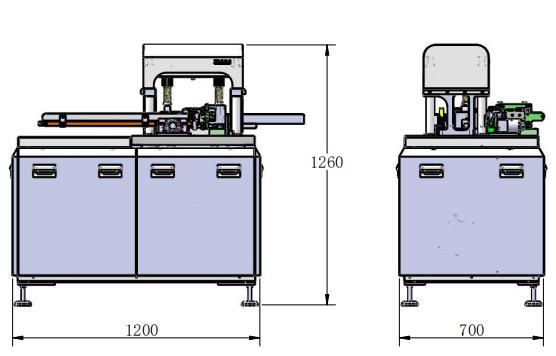

5.1 Downward Pull Type Sealing Machine

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

1 |

Suitable steel shell range |

18650 |

— |

2 |

Suitable height range |

60–80 mm |

— |

3 |

Rated voltage |

380V, 50 Hz |

— |

4 |

Rated power |

4 kW |

— |

5 |

Working air pressure |

5–6 kgf/cm² |

— |

6 |

Working efficiency |

50 pcs/min |

— |

7 |

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

8 |

Equipment weight |

500 kg |

Actual weight may vary |

9 |

Counting function |

Real-time counting function |

— |

10 |

Product pass rate |

≥99.5% |

— |

11 |

Equipment utilization rate |

≥99% |

— |

12 |

Equipment failure rate |

<1% |

— |

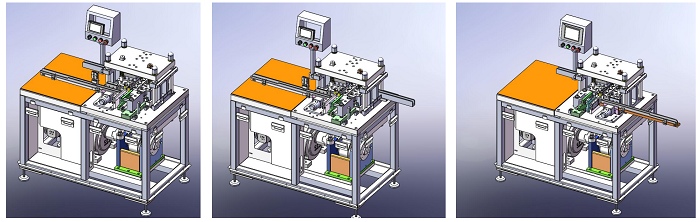

Feeding method:

To meet different customer requirements, our equipment can freely adjust the feeding and discharge method.

Right-in / Left-out Left-in / Right-out Left-in / Left-out

5.2 Docking Unit

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

1 |

Rated voltage |

220V, 50 Hz |

— |

2 |

Rated power |

60 W |

— |

3 |

Working air pressure |

5–6 kgf/cm² |

— |

4 |

Working efficiency |

>100 pcs/min |

— |

5 |

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

6 |

Equipment weight |

500 kg |

Actual weight may vary |

7 |

Counting function |

Real-time counting function |

— |

8 |

Product pass rate |

≥99.5% |

— |

9 |

Equipment utilization rate |

≥99% |

— |

10 |

Equipment failure rate |

<1% |

— |

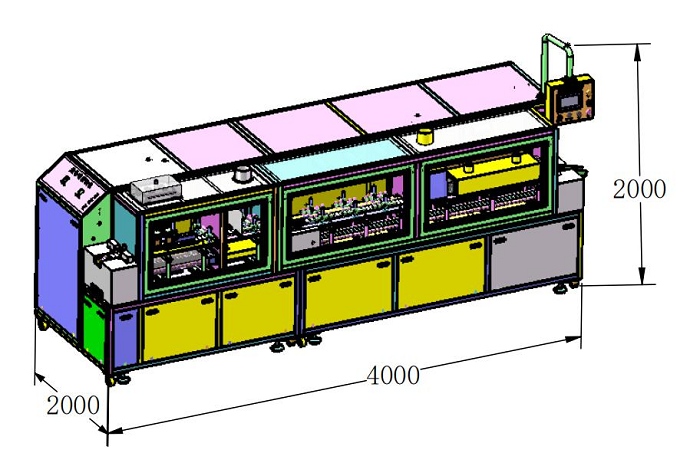

5.3 Automatic Cleaning Machine

No. |

Item |

Description |

Remarks |

1 |

Applicable range |

18650 steel shell battery |

— |

2 |

Equipment capacity |

>100 PPM |

— |

3 |

Equipment utilization rate |

≥98% |

— |

4 |

Product pass rate |

>99.5% |

— |

5 |

Working environment |

Temperature: 10–30°C, Humidity: 30–70% |

— |

6 |

Power supply configuration |

AC380V*5P / 50 Hz |

— |

7 |

Power |

20 kW |

— |

8 |

Equipment weight |

1954 kg |

— |

9 |

Overall dimensions (L×W×H) |

1200×4000×2000 mm |

— |

10 |

Compressed air |

≥0.6 MPa, 5 L/min |

— |

5.4 Automatic Boxing Machine

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

1 |

Applicable battery type |

18650 |

— |

2 |

Rated voltage |

220V, 50 Hz |

— |

3 |

Rated power |

600 W |

— |

4 |

Working air pressure |

5–6 kgf/cm² |

— |

5 |

Working efficiency |

>100 pcs/min |

— |

6 |

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

7 |

Equipment weight |

500 kg |

Actual weight may vary |

8 |

Counting function |

Real-time counting function |

— |

9 |

Product pass rate |

≥99.5% |

— |

10 |

Equipment utilization rate |

≥99% |

— |

11 |

Equipment failure rate |

<1% |

— |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com