products categories

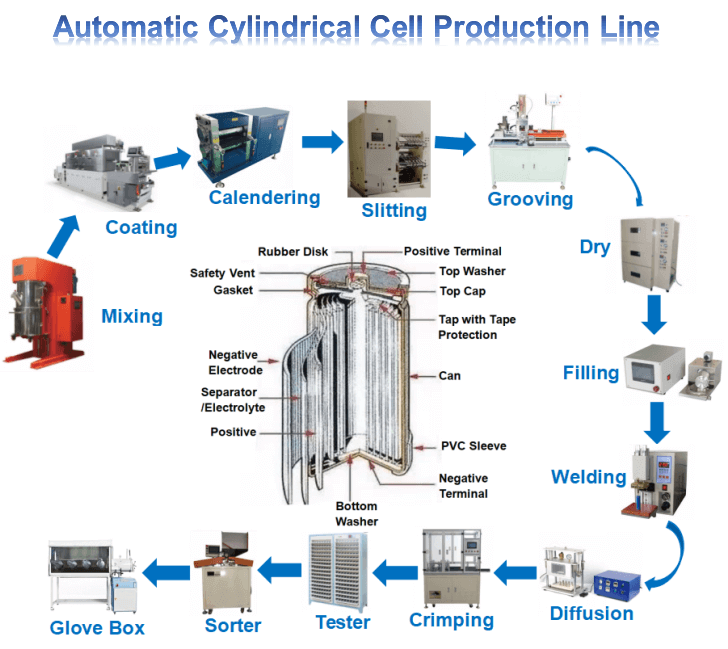

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic 4680 Cylindrical Battery Hydraulic Sealing Crimping Machine

Model Number:

TMAX-YAFK-46ANet Weight:

800lbsCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic 2 in 1 Cylindrical Cell Crimping and Cleaning Machine for Lithium-ion BatteryNext:

Automatic Cylindrical Battery Hydraulic Sealing Crimping Machine

Automatic 4680 Cylindrical Battery Hydraulic Sealing Crimping Machine

1. Equipment Description

1.1 Working Principle:

Powered by the hydraulic station's power transmission system, the hydraulic cylinder enables the equipment to run intermittently. Through the sliding movement of a high-precision, high-frequency guide rod guided by a copper-sleeved guide seat, the equipment exerts enormous pressure, pressing the battery shell and cap to the required process dimensions to realize battery sealing.

1.2 Performance Features:

This equipment integrates electrical and mechanical systems, with the entire production process fully automated under PLC control. It is characterized by low energy consumption, low operating cost, high efficiency, high precision, easy maintenance, and a low failure rate.

2. Main Technical Components

l Airtac cylinder

l Mitsubishi electrical control system

l Upper frame touch-screen fine adjustment control

l Jiazun sensors

l MEAN WELL power supply

l Safety protection devices

l Protective guard for the upper pressing plate

l Sealing molds for first seal, second seal, and third seal — key parts made from mold steel

3. Main Technical Structure

(Seven sections — A: Hydraulic Section, B: Feeding Section, C: Pushing Section, D: Mold Closing Section, E: Upper/Lower Sealing Mold Section, F: Discharging Section, G: Electrical Section)

(The entire machine is insulated and capable of live sealing operations.)

A. Hydraulic Section

l Equipped with a hydraulic cylinder of φ100 mm bore.

l The precision hydraulic cylinder generates high pressure via hydraulic drive; positioning guide columns operate in high-performance vertical reciprocation.

l Full mold positioning ensures low noise.

l Upper mold descends at low speed (pressure unchanged), with production efficiency of approx. 20–25 PPM (adjustable via frequency converter).

l Touch screen enables manual fine adjustment, human–machine interface, intelligent control, and convenient settings.

l Copper bushings and key connections use positioning pins to ensure easy disassembly and consistent alignment.

B. Feeding Section

l Extra-long conveyor increases loading quantity, extending operator activity time and reducing labor requirements.

l A row of magnets on the base of the feeding chute keeps cells upright; feeding direction: left-hand infeed.

l Taiwan TWT variable-speed motor drives wear-resistant feeding belt for accurate automatic delivery to each station.

l Transmission system adopts German NEY bearings.

C. Pushing Section

l Proximity sensors detect cell position and transmit signals quickly.

l Single cylinder drives a U-shaped pusher block to press-fit the cell cap. Pre-sealing mold includes capping function; first, second, and third seals are completed in one cycle.

l Push height adjustment mechanism allows left–right and vertical adjustment with positioning pins; side screws adjust the clearance between moving plates to ensure vertical push motion.

l Imported guide rail under push rod, with additional sliding table for flexible adjustment of push height position.

D. Mold Closing Section

l Airtac cylinders use pneumatic pressure to drive a bi-directional mold base for cyclic mold closing, completing continuous sealing.

l Mold bases are made from oil steel, heat-treated and precision-machined for wear, corrosion, and high-temperature resistance.

l High-precision positioning prevents upper mold from descending if mold closing is incomplete, protecting lower mold.

l Spring ejector pins position cells during mold closing to secure them.

l Mold clamping location precision is improved for easy mold installation/removal.

E. Mold Section

l Upper molds for first, second, and third seals all use a third-seal style, with mold center shafts precisely fitted to tapered center holes of the mold base.

l Mold base is positioned with locating pins for easy removal without losing center alignment.

l Key working areas of molds (upper/lower) are made from mold steel, with high precision, wear resistance, corrosion resistance, and high-temperature resistance.

l High-precision mold sleeves made from mold steel; upper molds have semi-circular locking blocks for secure fastening.

l Mold usage counting function, resettable only by manual operation.

l Non-manually damaged molds have a lifespan ≥ 2 million cells.

F. Discharging Section

l Discharge mechanism automatically unloads cells into the chute using a motor-driven belt.

l Discharge direction: left-hand outfeed.

l Both loading and unloading are operated from the left side, enabling full control by a single operator, greatly reducing labor costs.

G. Electrical Section

l “Manual” mode for mold adjustment/testing; switch to “Automatic” mode once process requirements are met.

l Mitsubishi electrical program ensures precise, safe, and reliable full-process monitoring.

l Multiple sensors connected with safety interlocks; solid-state relays control solenoid valves.

l Automatic alarm for abnormal conditions; stops automatically in case of incorrect operation.

l Equipped with emergency stop for immediate shutdown.

4. Product Accuracy

l Total Sealing Height Tolerance: ±0.1 mm

l Sealing Edge Height Tolerance: ±0.07 mm

l Final Diameter Tolerance: ±0.07 mm

l Diameter Concentricity Tolerance: ±0.07 mm

l Applicable Shell Type: 4680

l Applicable Height Range: 110 ± 2 mm

l No flaring or ovality after sealing (tolerance ±0.1 mm)

l No plating scratches or peeling after sealing

l Stable feeding without battery tipping

l High-precision mold alignment; no displacement under vibration

l All battery-contact parts made from stainless steel or anodized aluminum alloy for high electrolyte resistance

5. Key Mechanical Precision

l Lower Mold Flatness After Installation: ±0.02 mm

l Upper Mold Height Error: ±0.01 mm

l Upper Mold Diameter Error: ±0.01 mm

l Applicable Shell Type: 4680

l Applicable Height Range: 110 ± 2 mm

l No plating scratches or peeling after sealing

l All battery-contact parts made from stainless steel or anodized aluminum alloy for high electrolyte resistance

6. Installation Requirements

l Rated Voltage: 380 V, 50 Hz

l Rated Power: 4.5 kW

l Working Air Pressure: 5–6 kgf/cm²

l Efficiency: 20–25 pcs/min

l Dimensions (L×W×H): 1300 × 1150 × 1860 mm (subject to actual equipment)

l Weight: 1300 kg

l Documentation: 1 × Operation Manual, Electrical Component Layout Diagram

l Control Interface: Simple, reliable operation with full alarm and counting functions

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com