products categories

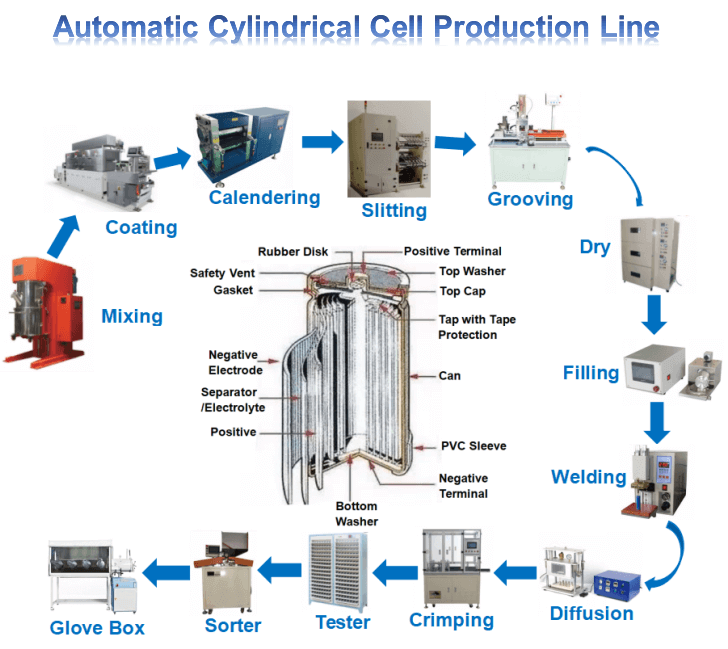

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Cylindrical Battery Hydraulic Sealing Crimping Machine

Model Number:

TMAX-YAFK-21ANet Weight:

800lbsCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic 4680 Cylindrical Battery Hydraulic Sealing Crimping MachineNext:

Automatic Cylinder Cell Vertical Grooving Machine

Automatic Cylindrical Battery Hydraulic Sealing Crimping Machine

1. Equipment Description

1.1 Working Principle

The hydraulic cylinder, driven by the hydraulic station power transmission device, enables intermittent motion. Using a copper-bushed guide seat in combination with high-precision high-frequency guide rods, the machine generates substantial pressure to press the battery case and cap to the process-required dimensions, achieving the sealing purpose.

1.2 Performance Features

The entire machine integrates electrical and mechanical systems, with production fully automated under PLC control. It offers low energy consumption, low cost, high efficiency, high precision, easy maintenance, and low failure rate.

2. Main Technical Specifications

l Airtac cylinders

l Mitsubishi electrical control system

l Touch screen fine adjustment control on upper frame

l ChuanZhun sensors

l MEAN WELL power supply

l Equipped with safety protection device

l Protective guard for upper pressing plate opening/closing

l Sealing: First, second, and third sealing molds, made of wear-resistant oil steel material

3. Main Components

A. Hydraulic Section

- A hydraulically driven precision cylinder produces substantial sealing pressure.

- Positioning guide pillars move vertically with high performance.

- Eight copper bushings ensure accurate positioning and wear resistance.

- Mold positioning is maintained throughout the process, with low noise.

- Touch screen for manual fine-tuning, HMI intelligent control, and easy settings.

B. Feeding Section

l Extra-long conveyor increases loading capacity, reduces operator workload.

l Transmission uses German NEY bearings.

l Taiwan TWT adjustable-speed motor drives wear-resistant feeding belt, ensuring accurate and safe material feed.

C. Pushing Section

l Intelligent sensors detect battery position and transmit signals quickly.

l Dual-axis positioning with single-cylinder U-shaped pusher block to pre-press battery caps.

l Pre-sealing mold integrates capping function; pre-sealing, second, and third sealing completed in one cycle.

D. Molding Section

- An Airtac cylinder drives the bidirectional mold base for cyclic sealing, accomplishing the third seal.

- The mold base is crafted from oil steel and heat-treated to achieve wear resistance, corrosion resistance, and high-temperature resistance.

- Optical fiber positioning avoids misaligned pressing; an automatic alarm is triggered if the position is incorrect.

- Sealing molds undergo special vacuum treatment and are made of imported high-quality materials.

- Under normal operation, the mold lifespan exceeds 600,000 cycles. - The third sealing mold is equipped with a usage counter (reset manually only).

E. Hydraulic Station

l Equipped with 5 MPa hydraulic station and 80 mm diameter hydraulic cylinder for sealing pressure.

F. Discharging Section

l Automatic unloading mechanism transfers finished cells to discharge chute.

l Loading and unloading on the same side for single-operator operation, reducing labor costs.

G. Electrical System

l Manual mode for mold adjustment/testing before switching to automatic operation.

l Mitsubishi PLC program monitors the entire process.

l Multiple sensors, safety light curtains, automatic alarms, and emergency stop function.

4. Specifications

Section |

Item |

Specification |

Specifications |

Rated Voltage |

380V, 50Hz |

Rated Power |

4.0 kW |

|

Working Air Pressure |

5–6 kgf/cm² |

|

Weight |

670 kg |

|

Efficiency |

40 pcs/min |

|

Dimensions (L×W×H) |

1160 × 700 × 1750 mm |

|

Basic Configuration |

Cylinder |

Airtac |

Electrical Control System |

Mitsubishi |

|

Touch Screen |

Fine adjustment type |

|

Sensors |

Yangming |

|

Power Supply |

MEAN WELL |

|

Safety Features |

Safety protection device |

|

Pressing Plate Guard |

Protective guard for pressing plate |

|

Sealing Molds |

Pre-seal, second seal, third seal, blunt seal; made from imported wear-resistant oil steel, hardness 60°–62° |

|

Technical Parameters |

Final Height Tolerance |

±0.05 mm |

Final Diameter Tolerance |

±0.05 mm |

|

Shoulder Height Consistency |

±0.05 mm |

|

Applicable Shell Type |

21-series cylindrical battery |

|

Applicable Height Range |

65–75 mm (requires mold change) |

|

Air-tightness Test |

≥1.2 MPa, hold for 5 min |

|

Post-Sealing Defect Tolerance |

No flaring or ovality after sealing (tolerance ±0.05 mm) |

|

Surface Quality |

No plating scratches or peeling after sealing |

|

Material Requirement |

All cell-contact parts made from stainless steel or anodized aluminum alloy for high electrolyte resistance |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com