products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Cylinder Cell Vertical Grooving Machine

Model Number:

TMAX-LSGC-18BDimension(L*W*H):

W1080mm*D660mm*H1200mNet Weight:

1000lbsCompliance:

CE CertifiedWarranty:

2 Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Cylindrical Battery Hydraulic Sealing Crimping MachineNext:

Automatic Cylindrical Cell Sealing Machine Cylinder Cell Crimping Machine

1. Equipment Description

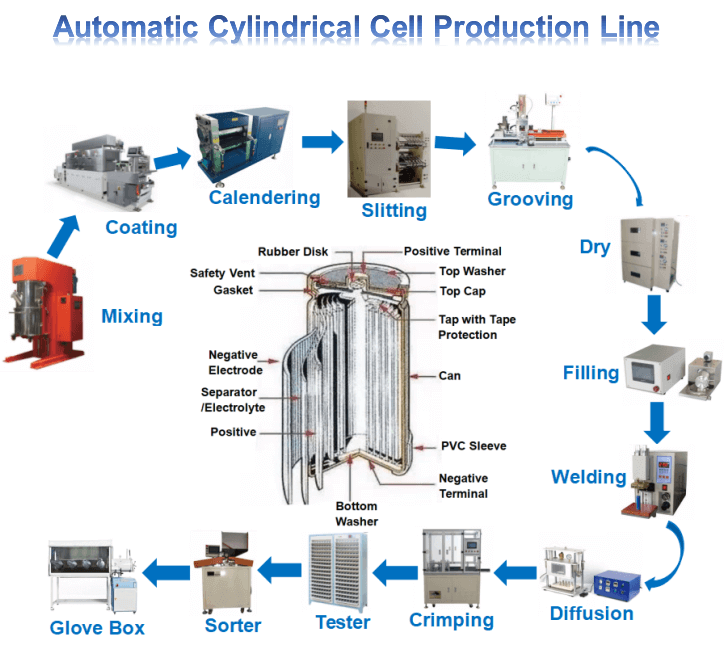

This equipment is intended for the grooving process of rechargeable Ni-MH, Ni-Cd, and cylindrical lithium-ion batteries. The grooving machine utilizes a PLC, intermediate relays, and time relays to control the coordinated actions of each cylinder. A motor drives the machine body at high speed, carrying out uniform automatic grooving on cylindrical steel cans with cells inside.

2. Main Configuration

No. |

Name |

Specification/Model |

Brand |

Remarks |

1 |

Cylinder |

— |

Airtac |

— |

2 |

Electrical Control System |

— |

Mitsubishi |

— |

3 |

Sensor |

— |

Yangming, Airtac |

— |

4 |

Power Supply |

— |

Omron |

— |

5 |

HMI |

7 inch |

Samkoon, Weintek |

— |

6 |

Electrical Components |

— |

Chint, Schneider |

— |

7 |

Adjustable Speed Motor |

— |

Taiwan-funded |

— |

8 |

Guide Rail |

— |

Hiwin, CPC |

— |

9 |

Guide Rail & Guide Post |

Custom-made |

— |

Brass, precision guide post |

10 |

Lower Aluminum Profile Frame |

— |

Domestic |

Anodized finish |

11 |

Equipment Parts |

Custom-made |

— |

Aluminum anodizing, steel chrome plating |

3. Basic Parameters

Item |

Specification |

Applicable Steel Can Model |

18650 |

Rated Voltage |

380 V, 50 Hz |

Rated Power |

0.75 kW |

Working Air Pressure |

0.5–0.6 MPa |

Weight |

175 kg |

Infeed/Outfeed Height from Floor |

Approx. 900 mm |

Overall Dimensions (L×W×H) |

1100 × 700 × 1250 mm |

Grooving Blade Thickness Tolerance |

±0.01 mm |

Blade Edge Surface Finish |

≥ 0.4 (μm Ra, measured with micrometer) |

Grooving Die Head Precision Tolerance |

±0.01 mm (micrometer measurement) |

Grooving Depth |

±0.02 mm (inside micrometer measurement) |

Grooving Die Head Concentricity |

±0.01 mm (dial gauge measurement) |

Concentricity of Grooving Die Head and Tailstock |

±0.02 mm (dial gauge measurement) |

4. Process Parameters

Dimension/Position Name |

Tolerance (mm) |

Grooving Concentricity |

±0.03 |

Grooving Inner Diameter Tolerance |

±0.03 |

Grooving Height Tolerance |

±0.03 |

Grooving Edge Height Tolerance |

±0.03 |

Steel can after grooving must have no flaring or ovality |

Flaring ≤ 0.08 |

Coating scratches, peeling, etc. |

None allowed |

5. List of Wear Parts

No. |

Part Name |

Specification/Model |

Quantity |

Remarks |

1 |

Grooving Blade |

— |

1 |

— |

2 |

Tailstock |

— |

1 |

— |

3 |

Grooving Die Head |

— |

1 |

— |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com