products categories

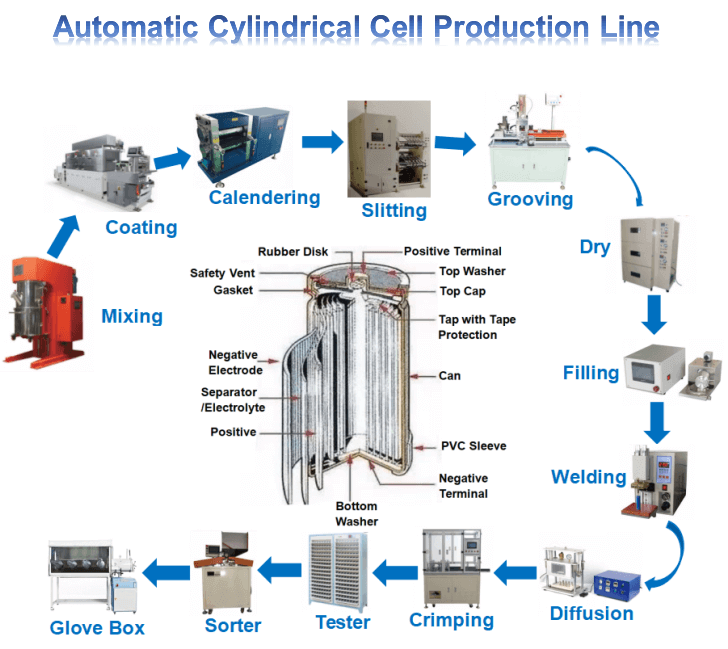

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Cylindrical Cell Sealing Machine Cylinder Cell Crimping Machine

Model Number:

TMAX-FKJ18650BNet Weight:

800lbsCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Cylinder Cell Vertical Grooving MachineNext:

Automatic 18650 Cylindrical Battery Laser PVC Stripping Machine

Automatic Cylindrical Cell Sealing Machine Cylinder Cell Crimping Machine

1. Equipment Function and Principle

l This linear-type sealing equipment is mainly used for crimp sealing cylindrical battery steel shells after electrolyte injection and cap assembly. It features safe and reliable operation, stable performance, and convenient operation.

l The cells are conveyed in a straight line for loading and unloading. The motor drives the crankshaft to pull down the first, second, and third sealing dies, as well as the crimping die, to sequentially perform the sealing of the cell steel shells.

2. Equipment Operation Process

*The operator picks up a full row of cells with a magnetic cell holder and places them on the infeed belt. The belt conveys the cells to the infeed pushing station. When the sensor detects the cells, the pusher cylinder pushes them to the sealing station.

*The upper die descends, and at the same time, the lower die base automatically closes to position the cell (the lower die closure is realized by the upper plate pressing down the closing guide rod, which makes the wedge block close the lower die base).

*While the lower die is closing for sealing, the next cell is fed in. The pusher block retracts, waiting for the next cell to enter the sealing die. After crimping, the upper plate ascends, the lower die base opens, and the cycle repeats. There are four sealing stations in all: first sealing, second sealing, third sealing, and crimping. The cell has to go through all stations to finish sealing.

*Operation sequence: Manual loading to infeed belt → Infeed belt conveys cells to sealing station → Pusher cylinder pushes cells one by one → Die closing, three-step sealing → Crimping → Cylinder pushes cells to discharge chute → Manual collection with magnetic holder.

3. Equipment Image (For Reference Only, Subject to Actual Product)

l Overall dimensions: 1150mm × 700mm × 1600mm

4. Technical Features

Utilizes crankshaft-connecting rod mechanical structure for strong stability.

High-precision sealing head and two-segment precision collet, all crafted from imported DC53 material.

Guide rod self-lubrication system (automatic oiling included).

PLC programmable control equipped with a touch screen human-machine interface, facilitating easy operation and setup.

5. Main Mechanism List

No. |

Mechanism Name |

Function |

Qty |

1 |

Magnetic Cell Holder |

Used for loading/unloading cells; can hold 6 cells at a time (manual use) |

1 set |

2 |

Loading Mechanism |

Continuously feeds cells to the die position; belt can hold about 40 cells |

1 set |

3 |

Cell Feeding Mechanism |

Cylinder pushes cells into the die position |

1 set |

4 |

Sealing Die Mechanism |

Collet positions cells, seals in three steps, and crimps to ensure consistent cell height |

1 set |

5 |

Main Drive Mechanism |

Brake gear motor drives crankshaft connecting rod; operates like a traditional mechanical press. Equipped with Shengbang GL-3700-20-S-M brake gear motor, driving crankshaft connecting rod and sealing head assembly for vertical motion and collet operation |

1 set |

6 |

Automatic Lubrication System |

Oil pump automatically lubricates connection points |

1 set |

7 |

Frame Structure |

A3 square tubing frame with baking paint, 45C high-precision chrome-plated platform, and upper/lower templates |

1 set |

8 |

Electrical Control System |

PLC control, touch screen operation |

1 set |

6. Main Configuration List

No. |

Mechanism |

Component |

Model |

Brand |

Qty |

1 |

Infeed/Outfeed Belt |

Gear Motor |

4GN25W25K |

Chuanming |

1 set |

Cylinder |

MA25*65SUM2 (with sensor) |

- |

1 set |

||

Cylinder |

TR16-30 Dual Rod (with sensor) |

- |

1 set |

||

Cylinder |

TR16-35 Dual Rod (with sensor) |

- |

1 set |

||

2 |

Main Drive |

Brake Gear Motor |

GL-3700-20-S-M (Horizontal gear reducer with brake, 3.7kW) |

Shengbang |

1 set |

Gear Pump |

220-150 |

Domestic |

1 set |

||

Bearing |

6010ZZ |

NSK/Harbin Bearing |

1 batch |

||

3 |

Electrical Control |

PLC |

CP1E-N20DR-A |

Omron |

1 set |

Touch Screen |

TH456-MT (with cable) |

Kunlun Tongtai |

1 set |

||

Solenoid Valve |

4V110-06-B |

Airtac |

3 sets |

||

Intermediate Relay |

LY2N-J DC24V |

Omron |

4 sets |

||

AC Contactor |

CJX2-1810 AC220V |

Chint |

3 pcs |

||

Thermal Overload Relay |

NR2-25 10A |

Omron |

1 pc |

l All pneumatic components brand: AIRTAC / SMC / CKD / CHELIC

7. Applicable Product Specifications

l The customer shall provide the grooved steel shell process dimensions and sealing process dimensions to the supplier.

8. Technical Specifications

Category |

Item |

Specification |

Machine Composition |

Lower Frame |

1 set, made of 50×50×5 square tubing + channel steel with baking paint finish |

Infeed Belt |

1 set, flat belt for continuous cell conveying |

|

Cell Feeding Mechanism |

1 set, cylinder-driven to deliver cells to sealing station |

|

Sealing Die Mechanism |

1 set, collet positions cells, performs three sealing steps, then crimping to ensure height consistency |

|

Crankshaft Mechanism |

1 set, driven by Shengbang GL-3700-20-S-M brake gear motor, driving crankshaft connecting rod for vertical motion and collet operation |

|

Discharge Chute |

1 set, cylinder ejects crimped cells into chute |

|

Electrical Control |

1 set, simple and user-friendly |

|

Basic Parameters |

Equipment Efficiency |

30 PPM (based on 21700 cell) |

Product Yield |

≥99.8% |

|

Equipment Availability |

≥95% |

|

Sealing Accuracy |

As per provided table |

|

Sealing Head Lifespan |

≥300,000 cycles |

|

Collet Lifespan |

≥500,000 cycles |

|

Infeed Belt Material |

PE synchronous belt, long service life |

|

Noise |

≤65 dB |

|

Factory Requirements |

Compressed Air |

≥0.4 MPa |

Input Voltage |

220V / 50Hz, 4 kW |

9. Consumables & Spare Parts List

No. |

Name |

Material/Model |

Qty |

Expected Lifespan |

1 |

First Sealing Upper Die |

DC53 HRC60 |

1 set |

≥300,000 cycles |

2 |

Second Sealing Upper Die |

DC53 HRC60 |

1 set |

≥300,000 cycles |

3 |

Third Sealing Upper Die |

DC53 HRC52-55 |

1 set |

≥300,000 cycles |

4 |

Third Sealing Upper Die Core Sleeve |

DC53 HRC57-60 |

1 set |

≥300,000 cycles |

5 |

Urethane Rubber |

PE |

1 set |

≥300,000 cycles |

6 |

Crimping Upper Die |

DC53 HRC60 |

1 set |

≥300,000 cycles |

7 |

Crimping Lower Die |

DC53 HRC60 |

1 set |

≥300,000 cycles |

8 |

Collet |

DC53 HRC52-55 |

1 set |

≥500,000 cycles |

10. General Configuration and Standards

1. Equipment color as per customer-provided color sample.

2. Noise ≤80 dB measured at 100mm from equipment outer wall.

3. Equipment complies with relevant national electromechanical safety standards and customer’s safety codes.

4. Supplied with Chinese operation manual and maintenance manual.

5. Supplied with electrical control diagram, pneumatic control diagram, purchased parts manuals, source code, etc.

6. Supplier to provide parts list and drawings for model changeover.

7. Spare parts list to include name, quantity, specifications, material, CAD drawing, brand, etc.

11. Equipment Operating Environment Requirements

1. Equipment Weight: approx. 500 kg

2. Ambient Temperature: determined by customer’s plant environment

3. Control Power Supply: 3-phase 380V, 50Hz, 5 kVA, voltage fluctuation range: +10% ~ -10%

4. Compressed Air: dried, filtered, regulated, output pressure > 6.0 kg/cm²

5. Vacuum: provided by customer, ≤ -80 kPa

6. Customer shall ensure good air circulation at the site.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com