products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Cylindrical Battery Laser PVC Stripping Machine

Model Number:

TMAX-18650PVCCompliance:

CE CertifiedWarranty:

Two Years Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Cylinder Cell Sealing Crimping MachineNext:

Semi-Automatic 18650 21700 Cylindrical Cell Winding Machine

Automatic Cylindrical Battery Laser PVC Stripping Machine

I. Equipment Overview

1.1 Equipment Application

l Designed for stripping the outer casing of 18650 cylindrical batteries.

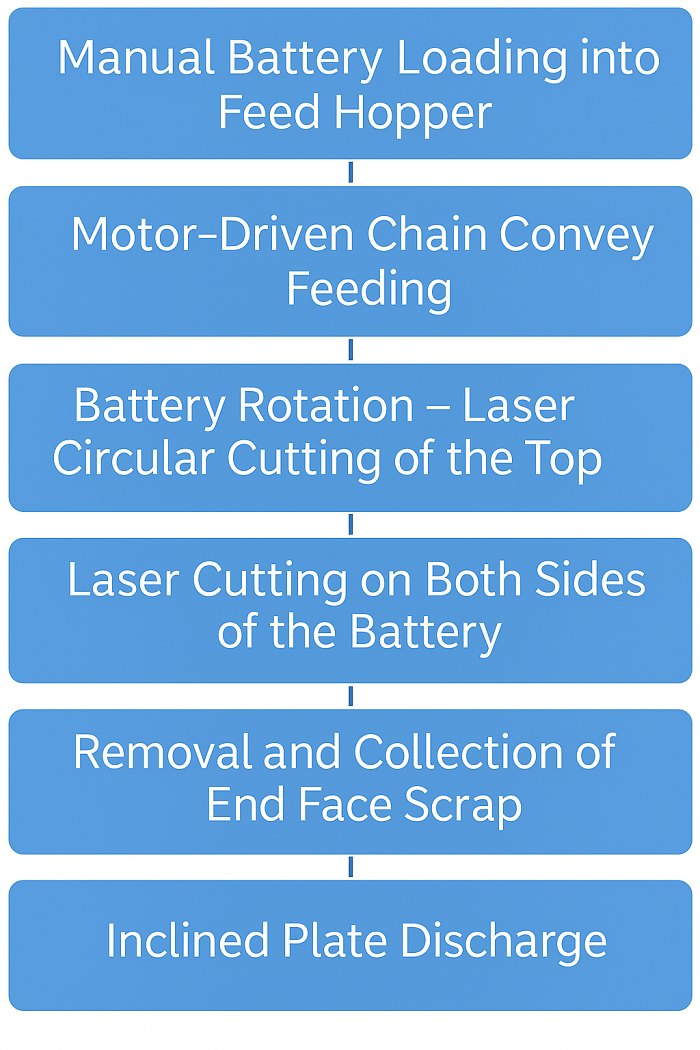

1.2 Equipment Operation Flow

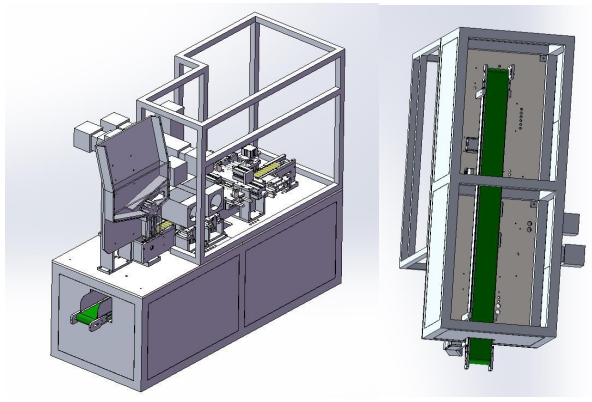

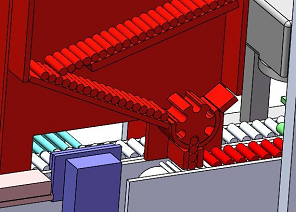

1.3 Equipment Diagram

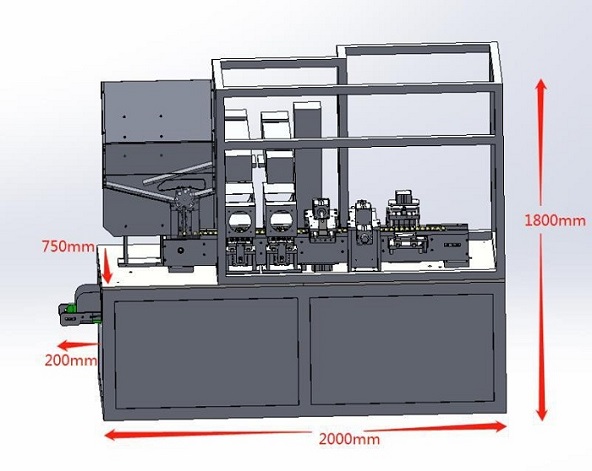

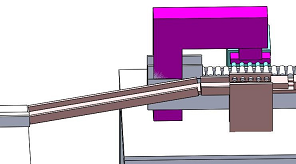

Overall Dimensions

l Laser Stripping Unit: 2000 mm × 750 mm × 1800 mm (L × W × H)

l Automatic Boxing Unit: 1000 mm × 700 mm × 1800 mm (L × W × H)

l Note: Dimensions are subject to the actual equipment.

Equipment Weight

l Total weight: approx. 1000 kg

1.4 Main Module Descriptions

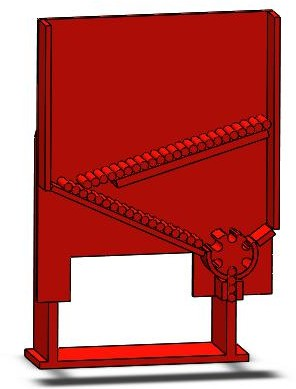

1.4.1 Manual Battery Loading into Feed Hopper

l Operator places batteries into the hopper; a feed wheel dispenses batteries into the chain conveyor.

1.4.2 Motor-Driven Chain Conveyor

l Stepper motor drives the chain to feed batteries one by one.

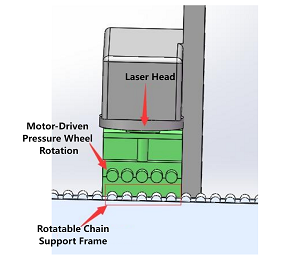

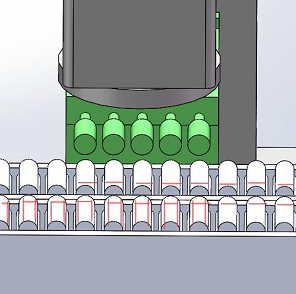

1.4.3 Laser Circumferential Cutting of Battery Heads

l Pressing mechanism holds the battery and rotates it; laser beam cuts the heads of 5 batteries simultaneously.

1.4.4 Rotary Transfer Mechanism

l Mechanical arm grabs 5 batteries, reorients them, and places them onto the second chain conveyor.

1.4.5 Dual-Side Laser Cutting

l Laser beam cuts two straight lines on each battery, centered on the body.

l Two parallel chain tracks enable simultaneous head cutting and side cutting.

1.4.6 End-Face Scrap Removal Mechanism

l Cylinders push 5 batteries into the scrap removal unit, where heads are clamped;

rear cylinders push batteries back to the track, discarding the head scrap;

scraps are collected in a bin under the workbench.

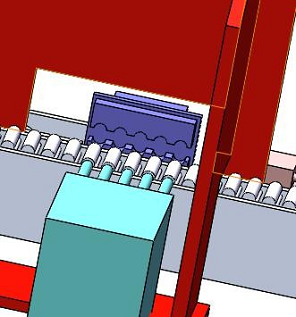

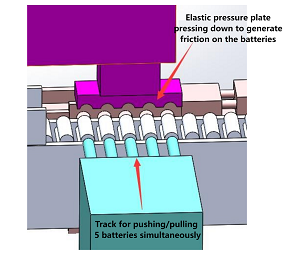

1.4.7 Steel Shell and Outer Film Separation

l Rubber plates position batteries top and bottom, increasing friction;

steel shell is pushed out for separation, leaving waste film on the track;

waste is carried down with the chain and collected in a bin under the workbench.

1.4.8 Inclined Plate Discharge

l Separated steel shells are discharged via a 1000 mm long inclined plate.

1.4.9 Automatic Boxing

l Automatically loads processed batteries into collection boxes.

1.4.10 Laser Section Enclosure with Exhaust Fan

l Laser cutting section is enclosed and equipped with exhaust ventilation.

II. Applicable Materials and Product Specifications

2.1 Supported Product Specifications

l 18650 cylindrical battery (Diameter: 18 mm, Height: 65 mm)

2.2 Process Documents

l As provided by Party A.

III. Equipment Specifications

3.1 Performance Parameters

1. Efficiency: >60–80 PPM

2. Equipment uptime rate: ≥99% (equipment-related downtime only)

3. First-pass yield: ≥99% (equipment-related defects only)

4. Automatic counting function included

5. Material collection position provided; layout optimized for single-operator use

6. Stripped batteries must have no appearance defects

3.2 General Parameters

Item |

Content |

Remarks |

|

Appearance Color |

As per Party A’s provided color sample |

— |

|

Operation Interface |

Chinese |

PLC + touchscreen |

|

Equipment Noise |

≤70 dB at 1 mm from outer wall |

Material-related noise (e.g., peeling) excluded |

|

Safety Standards |

Refer to GB5662.1 |

Mechanical and electrical protection requirements |

|

HC Series CO₂ Laser Machine Product Specifications Weight: 45 kg Laser Power: 30 W Laser Wavelength: 10.6 μm Marking Area: 110 × 110 mm Marking/Scanning Speed: 5,000–20,000 mm/s Input Voltage: 220 V / 50 Hz / 5 A Total Power Consumption: 350 W Cooling Method: Air cooling Protection Rating: IP54 |

|

||

IV. On-Site Environment Requirements (Provided by Party A)

1. Compressed Air Pressure: 0.4–0.8 MPa (4–8 kgf/cm²), flow ≤50 L/min

2. Dust Collection: Equipment supplied with dust collector to collect peeling waste; clean regularly

3. Ambient Temperature: 20–50 °C

4. Relative Humidity: 5–55% RH

5. Cleanroom Level: ≥ Class 100,000; no corrosive, explosive, or flammable gases or liquids present

Power Supply: Single-phase AC 220 V, 50 Hz; voltage fluctuation ≤ ±10%; power consumption 2.5 kVA

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com