products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

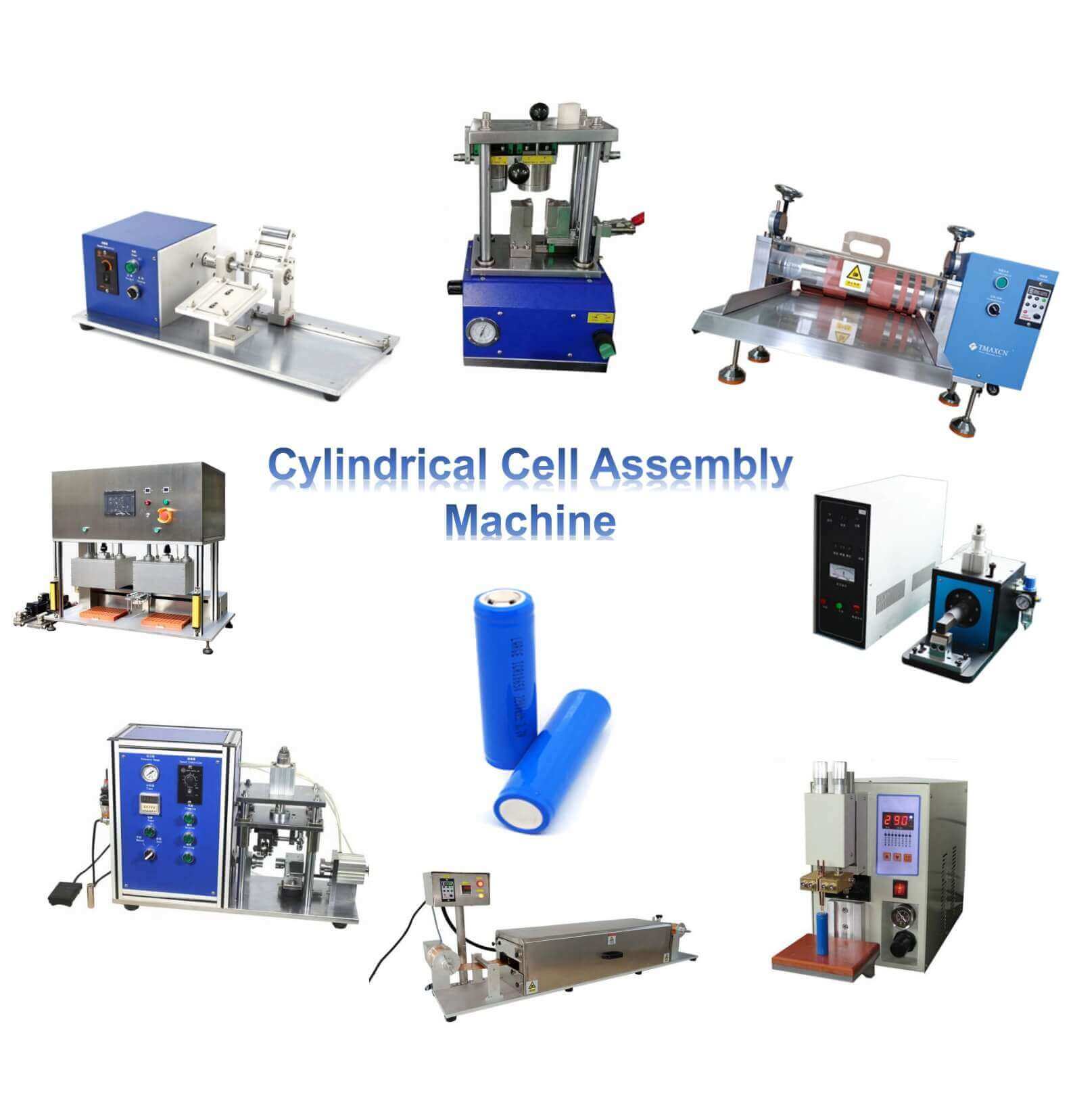

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

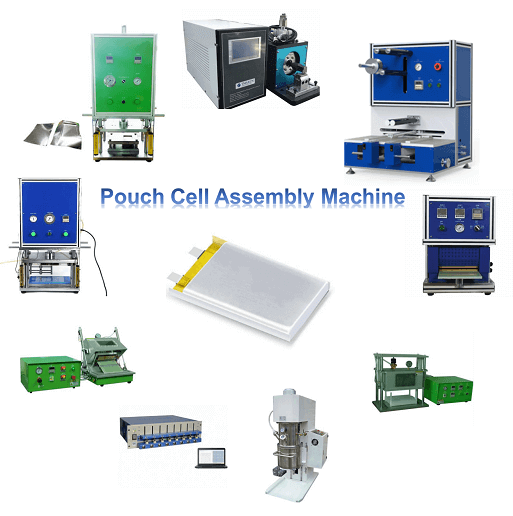

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

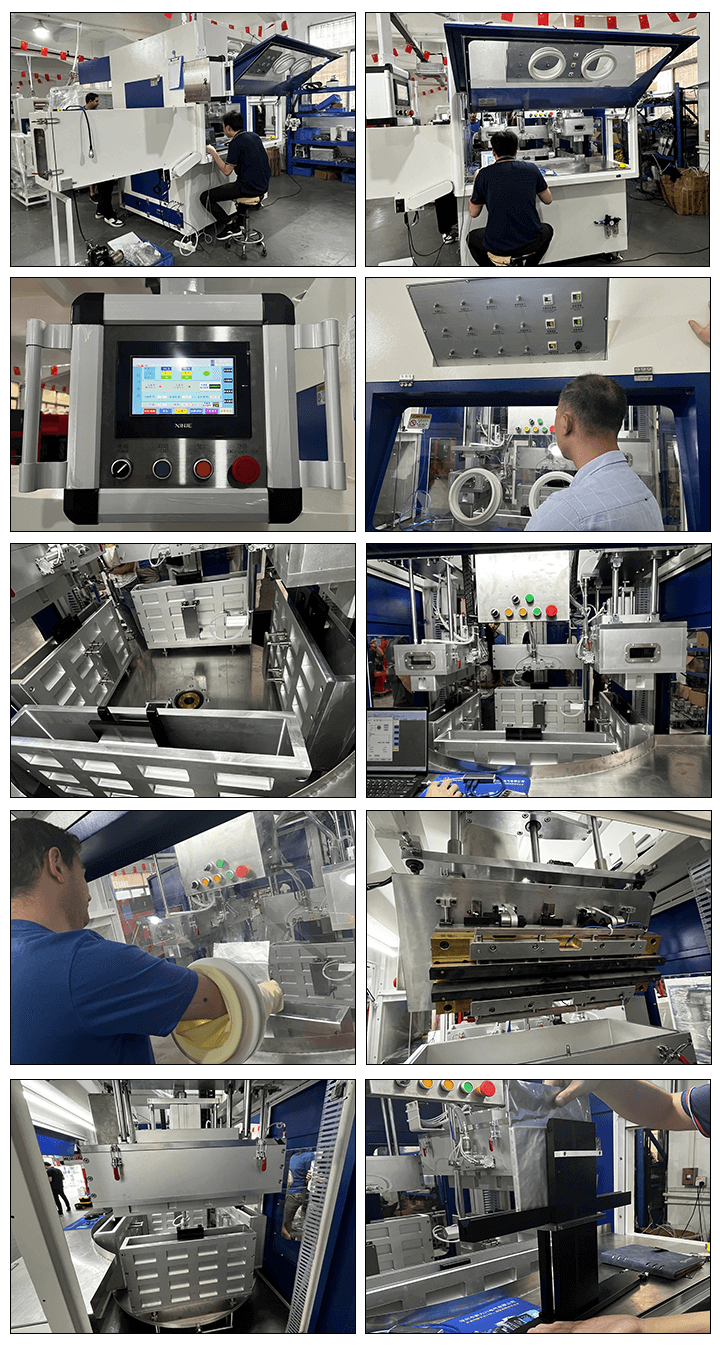

Automatic Electrolyte Filling Machine

Model Number:

TMAX-AEFCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Electrolyte Filling Machine with Double StationNext:

Battery Electrolyte Filling Machine for Lithium Ion Batteries Lab Equipment

Automatic Electrolyte Filling Machine

It is mainly used for manual feeding and discharging, automatic vacuum injection, vacuum diffusion°assing , shaping, automatic vacuum sealing and other functions of pouch cell lithium ion batteries.

Operation video:

Sequence number |

Name |

Function |

Quantity (set) |

1 |

Cell fixture |

Four cell at one time |

1 |

2 |

Four-station turntable |

Carry cell fixture,support the whole equipment |

1 |

3 |

Injection system |

store, keep,transfuse the electrolyte and remove bubbles |

1 |

4 |

Injection mechanism |

Vacuum injection into the opening cell |

1 |

5 |

Shaping&diffusion mechanism |

Vacuum diffusion°assing and shaping after electrolyte injection |

1 |

6 |

Pre-sealing mechanism |

Pre heat sealing the cell after diffusion°assing |

1 |

7 |

Frame |

Sealing, supporting |

1 |

Item |

Specification |

1.Electrolyte |

|

1 、component |

organic matter |

2、 Density |

1.0~1.5 g/cm3 |

2. Electrolyte |

|

1、Injection mode |

Vacuum injection of electric double-head pump |

2、Injection accuracy |

≤40g accuracy:±0.1g |

3、Infusion volume range |

10g-100g |

4、Precision of injection volume after sealing |

The accuracy of the weight after sealing and before injection can be less than (+0.2g). |

5、Diffusion°assing mode |

Secondary diffusion°assing, Maximum vacuum degree - 0.08 Mpa |

6、Diffusion°assing time |

Arbitrary setting of 1-99 seconds (Note: diffusion°assing time directly affects equipment efficiency) |

3.Sealing |

|

1、Sealing head width |

5 mm±0.1 mm (4-8mm changeable) |

2、Sealing head length |

170mm±0.2 mm |

3、Pressure |

0.1MPa~1MPa;Minimum adjustment accuracy is 0.1 MPa |

4、Time |

0.5s~99s;adjustable; |

5、Sealing head temperature |

room temperature~250℃;adjustable;accuracy:±1℃ |

6、Sealing performance |

Flat surface, no wrinkles, no bubbles, no stripping between the aluminium-plastic film, good sealing performance |

7、Sealing head material |

NAK80 |

8、Temperature display |

Display temperature deviation from actual temperature ±1℃ |

9、Temperature uniformity of sealing head |

The range of temperature distribution is less than ±2℃ |

10、Temperature rise speed |

It takes less than 20 minutes to rise from 25℃ to 200℃. |

5. Product |

|

1、First pass rate |

≥99% (Except for bad incoming materials, such as too short air bag to inject liquid, etc.) |

2、 Malfunction Rate |

≤5% |

3、Equipment production efficiency |

Actual production≥16PPM(Calculate according to four acceptance types of cells on each set of fixtures) |

Dry run≥20PPM(Calculate according to four acceptance types of cells on each set of fixtures) |

|

4 、Appearance |

Flatness, no wrinkles, no leakage, no drip, etc. |

5、Total weight of the whole machine |

About 3500kg;Ratio of total weight to bearing area≤500kg/m2 |

6、Maximum size of equipment |

L*W*H:2500mm×1700mm×2450mm |

Water, electricity and gas requirements |

|

Power supply |

AC380V ±10% 50Hz/60Hz Power:6KW(self-prepared) |

Compressed air source |

≥0.6MPa 30L/S (Utilization ratio:50%) |

Drying gas source |

≥0.6MPa(User-provided drying system) |

Vacuum source |

≤-0.09MPa 40L/S (self-prepared) |

Ambient temperature |

20~50℃;Relative humidity:0~90%RH(User-provided dehumidification system) |

Injection pump |

Two sets of electric injection pump(self-prepared) |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com