products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

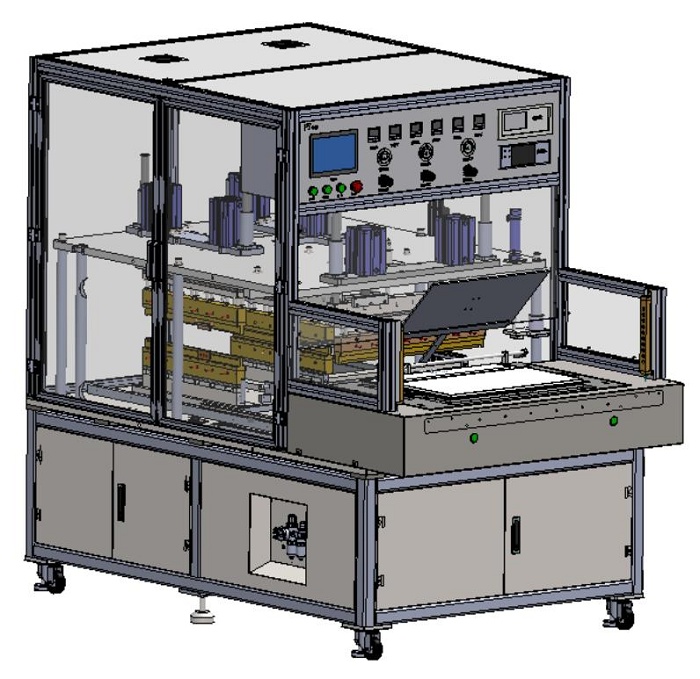

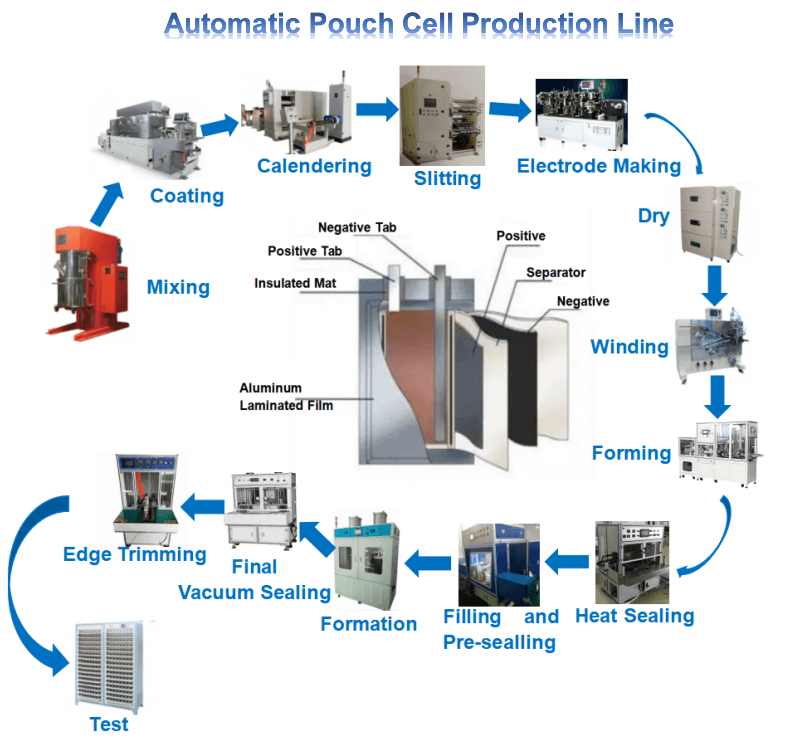

Automatic Linear 4-in-1 Top & Side Hot Sealing Machine Heat Sealer for Pouch Cell

Model Number:

TMAX-LDDCF-590Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Dual-Station Top and Side Hot Sealing Machine for Pouch Cell ProductionNext:

Automatic Case Forming Machine for Pouch Cell Production

Automatic Linear 4-in-1 Top & Side Hot Sealing Machine Heat Sealer for Pouch Cell

I. Functional Overview

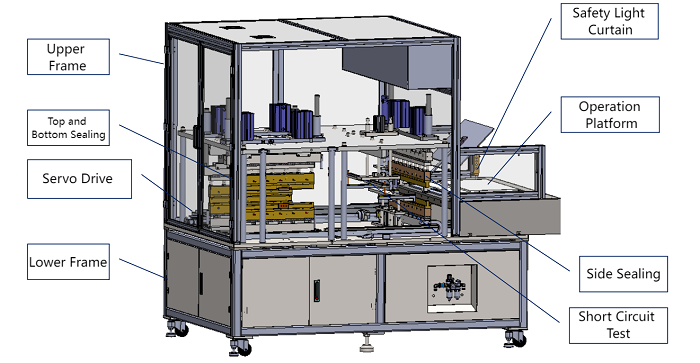

1. Applicable for top, bottom, and side heat sealing of pouch-type liquid lithium-ion batteries, as well as short circuit testing (Three testing modes: positive & negative tab test, positive tab vs. pierced aluminum laminate, negative tab vs. pierced aluminum laminate)

2. Process Flow:

A battery featuring dual tab outlets is situated in the upper and lower cavity jigs made of aluminum laminated film. The operator inserts the jig into the moving mechanism. A servo motor drives the lead screw to accurately transport the jig to the top/bottom sealing station, where the jig lowers to carry out top and bottom edge sealing.

Once sealed, the jig rises and is moved to the side sealing station, where it lowers again to finish side sealing. The jig is then transferred to the short circuit testing station, and the testing mechanism conducts the circuit check there.

In the end, the jig is sent back to the loading station through servo drive. The operator takes out the jig, loads a new one, and the next cycle begins.

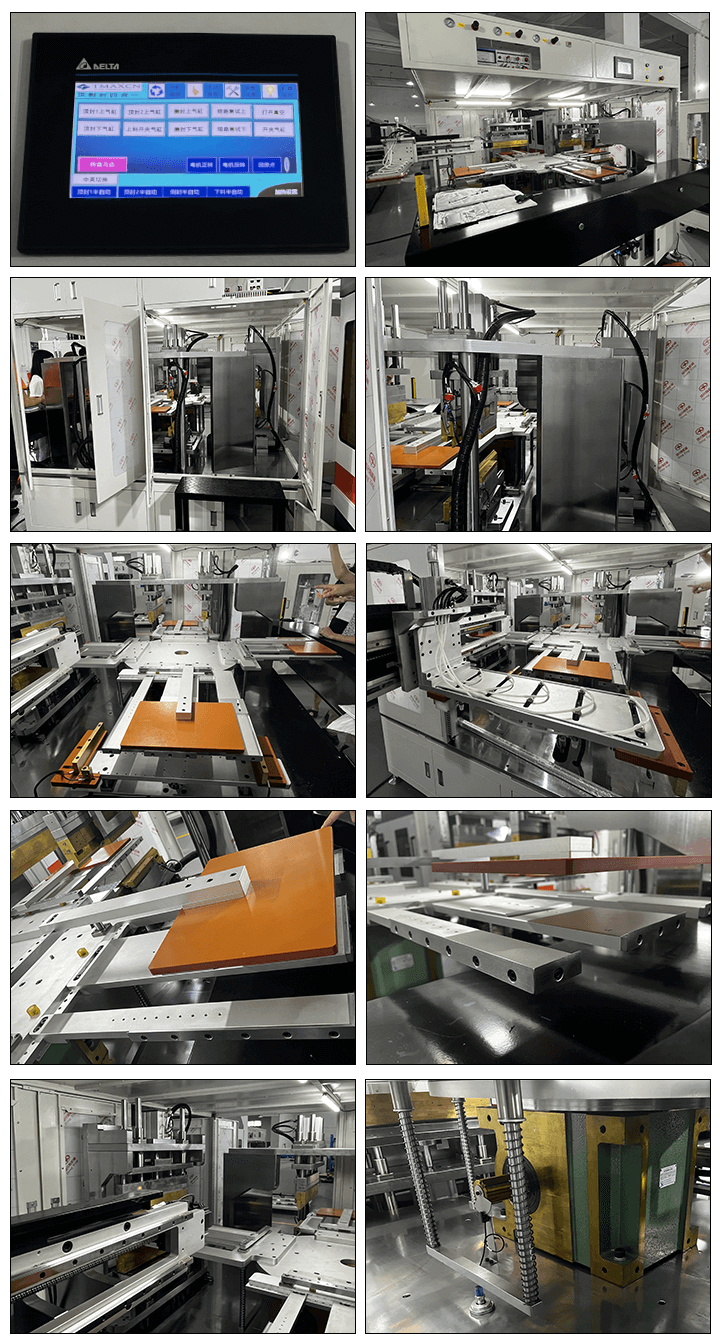

3. Equipment Diagram (Image for reference only)

II. Basic Specifications

1. Power Supply: AC220V / 50Hz

Rated Power: 7.0 KW

2. Compressed Air: ≥0.6 MPa, 20 L/min (provided by customer)

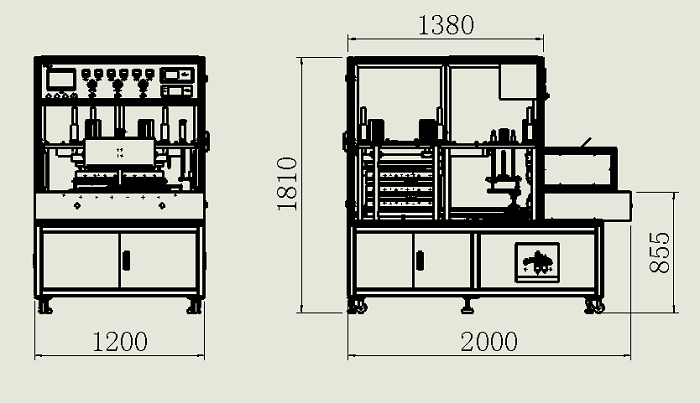

3. Machine Dimensions (L×W×H): Approx. 2000 mm × 1200 mm × 1810 mm

4. Machine Weight: Approx. 1400 kg

5. Paint Color: International Warm Gray 1C (or per supplier standard)

III. Technical Parameters

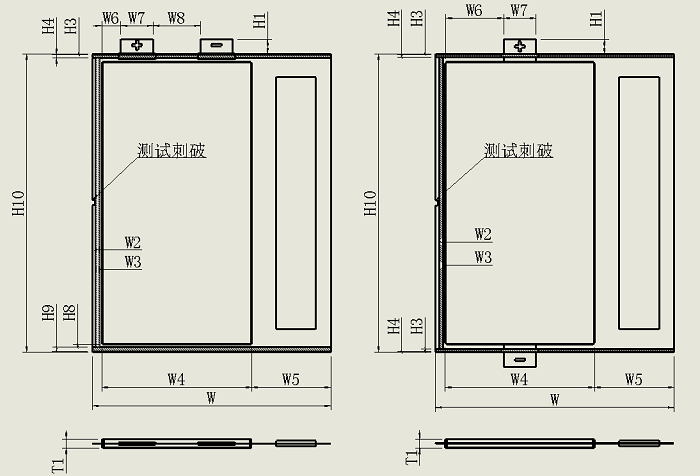

1. Compatible Battery Specifications

Item |

Value (mm) |

Item |

Value (mm) |

Top Seal Length W |

170–480 |

Cell Width W4 |

90–300 |

Top Unsealed Edge H3 |

1–3 |

Pouch Side Width W5 |

50–150 |

Top Seal Width H4 |

6 |

Cell Thickness T1 |

5–18 |

Bottom Seal Width H9 |

8 |

Tab Eccentricity (Cell Body) W7 |

5–80 |

Bottom Unsealed H8 |

0.5–2 |

||

Side Seal Length H10 |

90-600 |

Tab Width W7 |

30–100 |

Side Seal Width W2 |

8 |

Tab Center Distance W8 |

10–160 |

Side Unsealed Width W3 |

0.5–2 |

Tab Height H1 |

30 |

Reference Battery Dimensions:

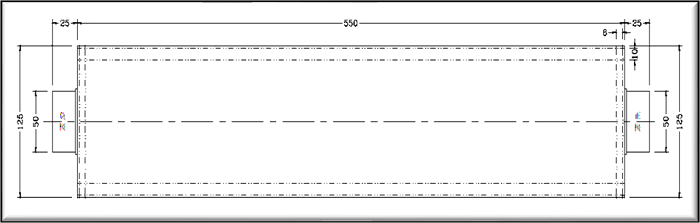

l Top Seal Strip: Length ≥280 mm, Width: 6 mm, Soft Seal

l Side Seal Strip: Length ≥580 mm, Width: 8 mm, Hard Seal

2. Sealing Width: 5–15 mm

3. Sealing Thickness: 0.14–0.3 mm

4. Sealing Head Temperature:

– Adjustable from ambient to 230°C, with compensation function

– Control Accuracy: ±2°C

– Sealing Time: 0–99.9 seconds adjustable

– Heat Sealing Temp Range: Ambient ~250°C, adjustable

– Temperature Uniformity: ±3°C

– Display Accuracy: ±1°C

5. Sealing Head Parallelism: ±0.01 mm

– Testable with triplicate carbonless paper

– Under 0.6 MPa and 200°C, uniform sealing is expected

6. Machine Capacity: 2–3 PPM (Depending on process settings and operator skill)

7. Machine Availability Rate: 95%

8. Product Yield Rate: 99%

IV. Process Features

1. Linear servo-driven linear structure with high positioning accuracy

2. Jig lifting by pneumatic cylinder, featuring fixed lower head and movable upper sealing head

3. Manual jig replacement for quick switching

4. Manual loading of aluminum laminated film and battery cell

5. Comprehensive safety design:

– Dual-button start

– All moving parts enclosed in protective covers

6. PLC automatic control with HMI touchscreen interface for easy operation

7. Production statistics, manual/automatic mode switching, and fault alarm functions

8. Safe, stable, reliable, and user-friendly

V. Main Components

(1) Mechanical Components:

1. Battery positioning jig: Special clamping fixture for battery loading/unloading with quick positioning capability

2. Jig transfer mechanism: Servo motor-driven precision ball screw for jig positioning

3. Top & bottom sealing unit: Dual sealing structure comprising cylinders, guide posts, copper heating blocks, insulation plates, sealing heads, and temperature control

4. Side sealing unit: Single side sealing featuring cylinders, guide posts, copper heating blocks, insulation plates, sealing head, and temperature control

5. Testing unit: Equipped with probe mechanism, puncture unit, cylinders, guide posts, testing platform, and short-circuit tester

6. Frame platform: Aluminum alloy frame with square tube welded structure, thickened chrome-plated steel plate platform, hardened chrome columns, and painted sheet metal enclosures

7. Control system: Incorporates PLC, HMI, cylinders, solenoid valves, servo motors, gear reducers, guide rails, and ball screws; featuring production statistics and fault alarm functions

(2) Electrical and Standard Components:

1. Pneumatic Components:

– Taiwan brand cylinders, pressure regulators, pressure gauges, solenoid valves, pneumatic connectors

– PLC, touchscreen (includes timer, counter), safety light curtain, emergency stop, switch buttons

2. Standard Electrical Components:

Component |

Brand Options |

PLC |

Inovance / Panasonic / Omron |

HMI |

Weinview / Inovance / Omron |

Servo Motors |

Panasonic / Omron / Inovance |

Safety Light Curtain |

SICK / KEYENCE / Omron |

Electrical Components |

Chint / Schneider |

Solid-State Relays |

Omron / Honeywell / Siemens |

Solenoid Valves |

AIRTAC / CKD / Chint |

Cylinders |

AIRTAC / SMC / CKD |

Ball Screws / Guides |

HIWIN / TBI / THK |

Insulation Resistance Tester |

To be provided by customer |

VI. Equipment Reference Diagram

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com