products categories

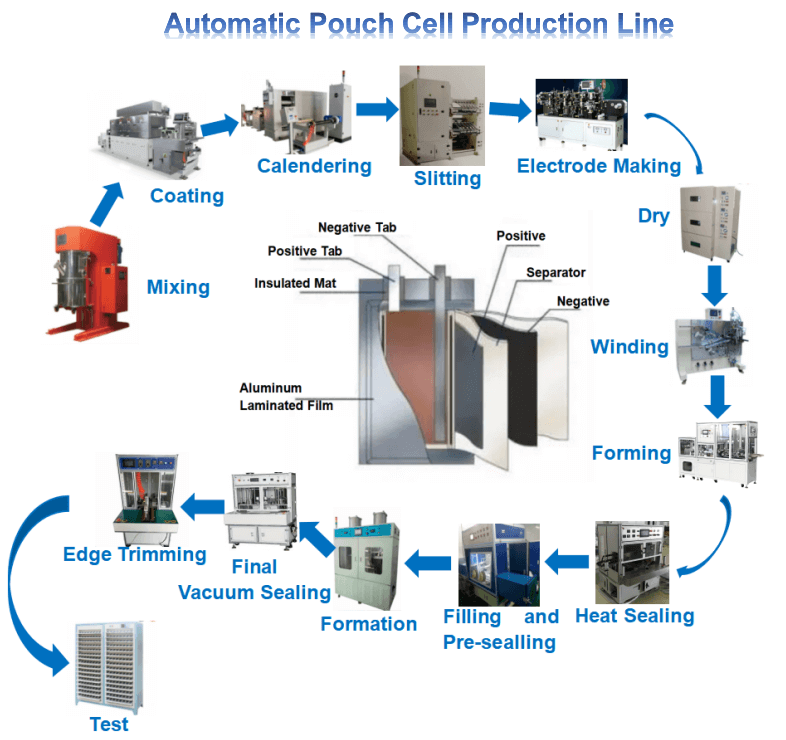

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Case Forming Machine for Pouch Cell Production

Model Number:

TMAX-LDCK-120Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Linear 4-in-1 Top & Side Hot Sealing Machine Heat Sealer for Pouch CellNext:

200L Pneumatic Lifter for Mixer

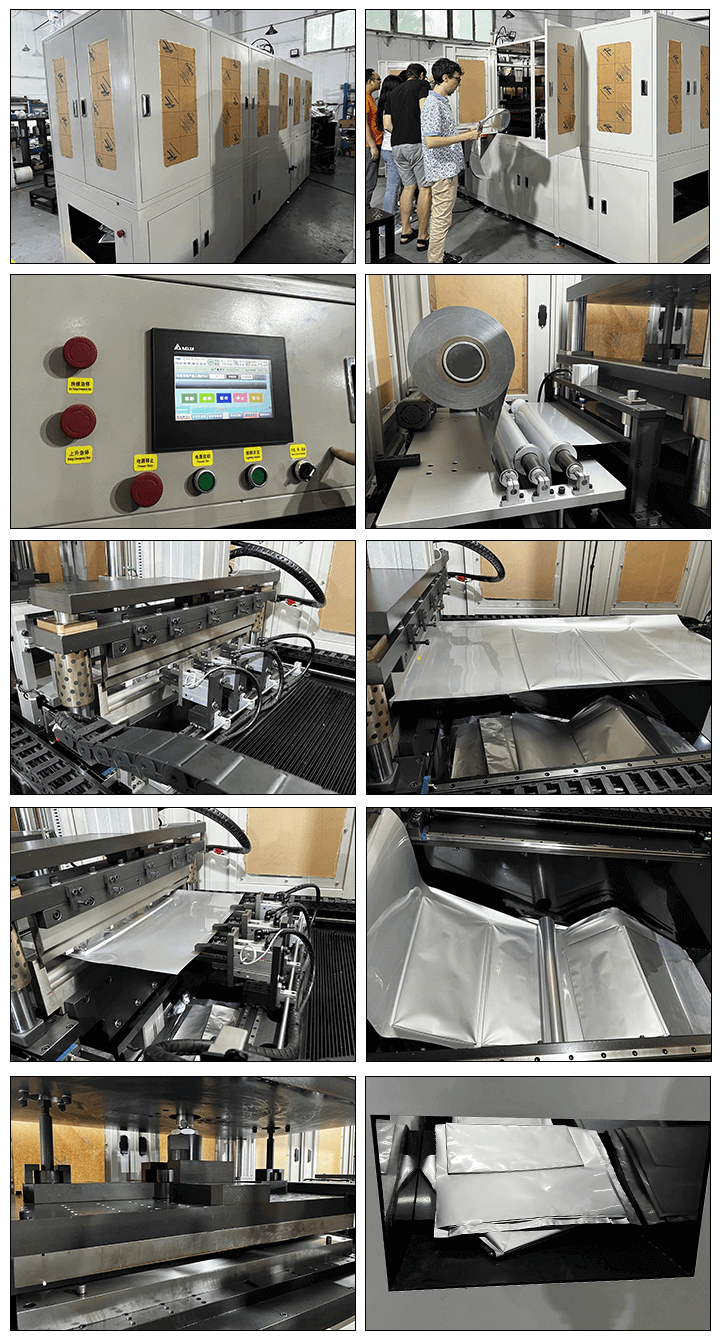

Automatic Case Forming Machine for Pouch Cell Production

1. Equipment Overview

1.1 Equipment Function and Operating Principle

– Equipment Function:

1.1.1 Servo motor-driven manipulator for material feeding, with adjustable feeding length up to 240 mm;

1.1.2 Cutter movement controlled by laser sensor and servo drive, ensuring cutting precision within ±0.15 mm;

1.1.3 All machine actions are controlled by PLC and realized via touchscreen HMI.

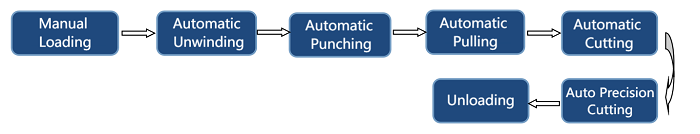

– Operating Principle:

A speed-regulating motor drives the air shaft to unwind the material, with PLC-controlled servo stamping, and servo motor-driven manipulator for material pulling.

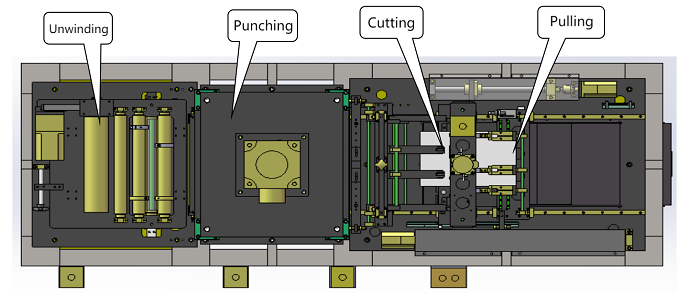

1.2 Equipment Operation Process

1.2.1 The feeding manipulator grips the material and conveys it to the target position as per the preset distance.

1.2.2 When arriving at the target position, the booster cylinder drives the upper mold to close and hold pressure. The lower servo motor moves upward, pushing the punch to carry out deep drawing.

1.2.3 After forming, the punch withdraws, and the upper mold is lifted under servo control.

1.2.4 The motor-driven transfer system positions the material at a fixed distance.

1.2.5 Once positioned, the cutter moves to the cutting position. The cylinder lowers the cutter to perform trimming, ensuring sealing precision.

1.2.6 The transfer mechanism resets and the next cycle starts.

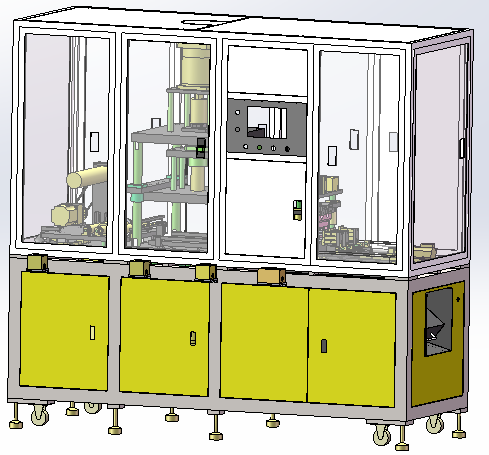

1.3 Overall Structure

Machine Dimensions: L 2020 mm × W 740 mm × H 1980 mm (for reference only)

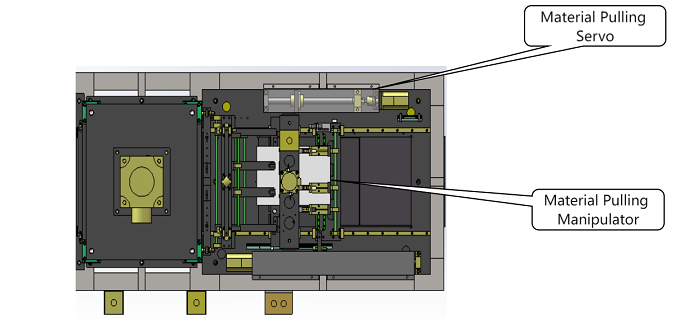

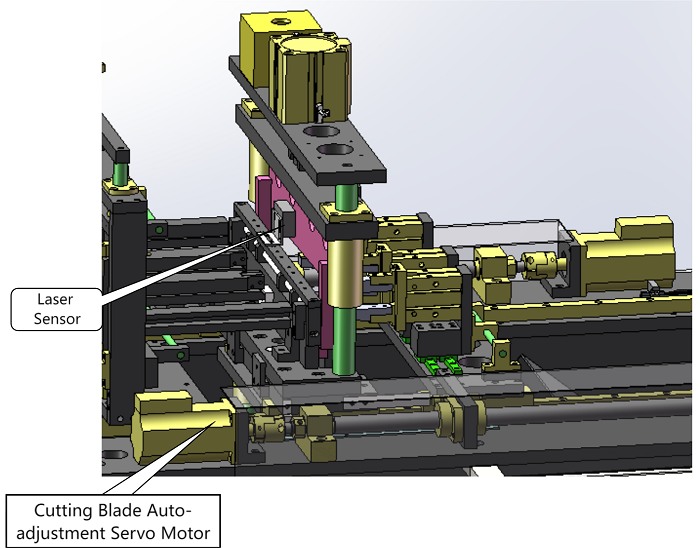

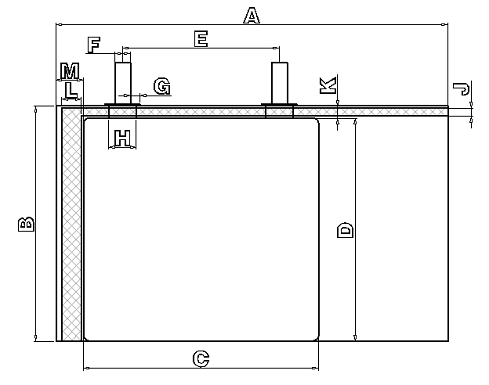

1.4 Main Components (with diagrams)

1.4.1 Feeding Section

1. Floating roller tension device; material guide rollers made of plastic steel

2. Automatic fiber optic web guiding system integrated with the feeding mechanism

3. Unwinding driven by speed-adjustable motor; cantilever-type air shaft for material roll fixing

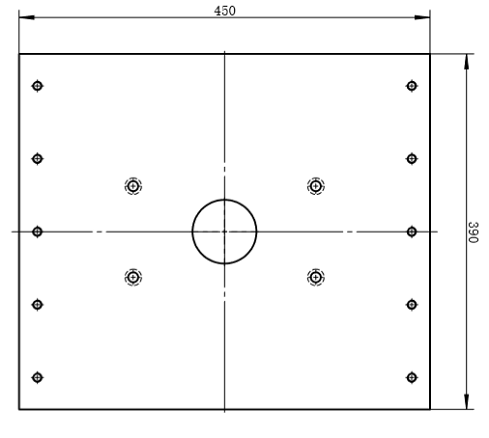

1.4.2 Stamping Section

1. Power Section: The upper mold is driven by a booster cylinder; the lower mold is driven by a servo motor.

2. For case punching, the motion is powered by a booster cylinder. The control software supports two-step stamping functions. The servo motor on the upper mold provides an effective stroke of at least 40mm and meets the power requirements for the maximum product size specified in the technical specifications (over 750W). It is equipped with a corresponding reducer and coupling. The lifting platform is guided by ball guide posts for stable vertical movement.

The height between the working surface of the material transfer mechanism and the mold mounting base plate: 15-50mm.

3. The stamping part of the equipment (mold position) is fitted with safety light curtains on the front and rear doors, with no blind spots to ensure operator safety. Each front and rear door in the middle section of the equipment is equipped with a door switch for personnel protection.

4. The upper mold is connected via an L450mm × W390mm × T40mm 45# steel plate, along with four sets of Ø40mm guide posts and linear bearings.

1.4.3 Pulling Section

1. Servo motor drives the pulling unit with edge-guided alignment; travel is adjustable, travel range ≥350 mm

2. Material press mechanism installed in front of pulling section

3. Material clamping is achieved by an independent cylinder; clamping blocks are made of anti-slip material

1.4.4 Cutting Mechanism

1. Cutter up-down motion guided by guide pillars and bushings

2. Distance between upper and lower cutters after reset: ≥60 mm

3. The cutting assembly is position adjustable, guided by a rail; travel range ≥200 mm, effective blade width ≥335 mm

4. After pulling, the cutter moves right to a fixed-length cutting position to trim the end of the product, then automatically moves to the high point of the previous foil cavity. After detecting the cavity, the cutter moves a fixed length to cut the waste, ensuring sealing position accuracy

1.4.5 Frame Structure

1. Upper frame constructed from standard aluminum profiles; lower frame fabricated from 60×60 mm square steel tubes with 4 mm thickness, welded and painted.

2. All protective doors (excluding the feeding side) made of sheet metal; top doors incorporate viewing windows; each door equipped with a safety sensor; sheet metal thickness ≥1.5 mm.

3. Resin mufflers installed on all exhaust ports of solenoid valves and manifold blocks.

4. Noise reduction measures applied to all air pipes and cable entry/exit points.

5. Noise level of all machine sections: ≤80 dB.

1.4.6 Control Section

1. 65536-color true-color touchscreen

2. HMI shall be intuitive and user-friendly; buttons dimensioned to avoid accidental double-pressing

3. Panel-mounted hardware buttons: Power ON/OFF, Start, Stop (latching), Emergency Stop

4. All stations operable manually via HMI, each with a single-function interface; related actions grouped on the same screen, no page navigation required

5. HMI must show cumulative and shift-specific Pocket forming and cutting counts, with reset capability

6. Comprehensive fault alarm and self-diagnosis functions required; component names in alarm messages must exactly match HMI labels

7. In manual mode, interlocking logic must be implemented between interdependent actions of each functional unit

1.5 Key Components

Item |

Component |

Brand |

1.5.1 |

Pneumatic Components |

AirTAC / YSC |

1.5.2 |

Switches / Electrical Components |

Chint |

1.5.3 |

Sensors |

Panasonic / Omron / Keyence |

1.5.4 |

PLC |

Panasonic |

1.5.5 |

Touchscreen |

Delta |

1.5.6 |

Ball Screw / Linear Rail |

TBI / Dinghan |

1.5.7 |

Motors & Drivers |

Mitsubishi |

1.5.8 |

Machine Frame |

Lower: square tube welded + painted; Upper: aluminum profile + transparent acrylic panels |

II. Applicable Incoming Materials and Product Specifications

2.1 Incoming Material Dimensions: Ø350 mm × 300 mm (W)

2.2 Maximum Battery Product Dimensions:

Length: 120 mm (Double-Pit B)

Width: 300 mm (including airbag A)

Code |

Name |

Parameter |

A |

Case width (incl. gas bag) |

60–300 mm |

C |

Body width |

30–250 mm |

B |

Body length |

30–120 mm |

2.3 This equipment comes equipped with one integrated mold, with changeover time of 0.5–1 hour/person, and is compatible with buyer's existing split-type molds

III. Equipment Technical Specifications

3.1 Equipment Acceptance Specification Sheet

Equipment Acceptance Specification Sheet

Item |

Description |

Requirement |

Equipment Performance |

Efficiency, Quality |

First-pass yield ≥99.5% (excluding defective incoming material) |

Product Quality |

Servo system repeat positioning accuracy: ±0.03 mm |

|

Cutting Precision |

±0.15 mm |

|

Capacity |

PPM: <30 PPM (based on 2 pcs per cycle), <15 PPM (based on 1 pcs per cycle) |

|

Machine Failure Rate |

≤5% |

|

Product Changeover |

Changeover time ≤1 hour/person (excluding mold tuning time) |

|

Material Compatibility |

Ø350 mm × 300 mm |

|

Mechanical Section |

Equipment Dimensions |

L 2020 mm × W 725 mm × H 1900 mm |

Machine Weight |

Load-bearing ratio: <500 kg/m² |

|

Main Component Selection |

Ball screw/linear rail: TBI / Dinghan |

|

Cutting mechanism standardized |

||

Wearing parts standardized |

||

Electrical Section |

Power Input |

4.5 kW, 3-phase 380V |

Main Component Selection |

Pneumatic: AirTAC / YSC |

|

Sensors: Panasonic / Omron / Keyence |

||

PLC: Panasonic |

||

Motors & Drives: Mitsubishi |

||

Switches & Electrical: Chint |

||

Touchscreen: Delta |

||

Electrical Wiring |

All wiring, gas pipes, and tubing must be clearly labeled |

|

PLC must reserve at least 5 I/O terminals and communication ports (Ethernet, RS232, etc.) |

||

Software |

Provide PLC source code for equipment operation control and HMI touchscreen program source code (with annotations) |

|

Provide all required software installations, including drivers, industrial control card software, etc. |

IV. Equipment Installation Requirements

4.1 Electrical:

– Power: 4.5 kW, 3-phase AC 380V

4.2 Compressed Air:

– ≥0.5 MPa, 20 L/min

4.3 Weight:

– Total: Approx. 800–1500 kg

– Load-bearing ratio: ≤500 kg/m²

4.4 Environment:

– Room temperature: 10–40°C

– Humidity: 30–70% (no condensation)

– No flammable or corrosive gases

4.5 Machine Frame:

– Reinforced structure, suitable for forklift transport

4.6 Installation Location:

– Standard workshop

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com