products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

200L Pneumatic Lifter for Mixer

Model Number:

TMAX-QTSJ200Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Case Forming Machine for Pouch Cell ProductionNext:

High-Precision Slurry De-ironing Filtration & Transfer System

200L Pneumatic Lifter for Mixer

I. Equipment Features

Application Scope

l Lifting the transfer barrel cover assembly.

II. Main Equipment Parameters

Control System & Performance

l Air Pressure: 0.5 – 0.6 MPa (dry compressed air)

l Air Consumption: 15 L/min

l Lift Control Panel: Manual directional valve with self‑lock

l Control Mode: Manual

l Rated Load: ≤ 360 kg

l Machine Weight: ≈ 420 kg

l Dimensions: L 1290 × W 1220 × H 1691 mm (raised 2491 mm)

l Color: Off‑white

l Floor Load: 400 kg/m²

III. Key Components Brand

No. |

Item |

Spec. |

Material |

Qty |

Brand |

1 |

Cylinder |

ΦD × ΦN |

Al‑alloy |

1 |

Airtac |

2 |

Pneumatic Valve |

– |

– |

1 |

Airtac |

IV. Supporting Conditions

No. |

Item |

Standard Requirements |

1 |

Workshop Height |

> 2.5 m; ensure lift clearance |

2 |

Door Size |

H > 2.0 m; W > 1.0 m |

3 |

Heating |

Room > 20 °C to keep lubricants fluid |

4 |

Installation Space |

As per layout |

5 |

Others |

No corrosive / explosive gases or liquids |

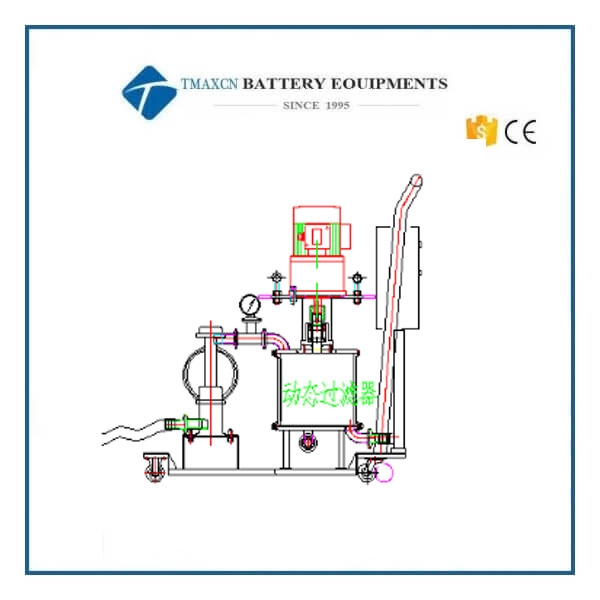

Slurry De-Ironing, Filtration & Transfer System

Model: HDCG-3/4"-3

I. Process Diagram & Description

1. Slurry stored in the transfer tank is pumped (diaphragm pump) through pipelines for filtration & de‑ironing, then delivered to the coating‑machine hopper.

2. All components are connected via quick fittings and fixed on a stainless tray; transfer is managed by the control system & piping.

3. Note: Valve & level‑control between this system and the coating hopper/tank shall be installed and managed by the customer & coater supplier.

II. Equipment Configuration & Capacity

No. |

Name |

Spec. / Model |

Unit |

Qty |

Remarks |

1 |

Pneumatic Diaphragm Pump |

3/4" – Skylink or Graco |

set |

1 |

with ISO quick clamp |

2 |

Filter Cartridge |

Φ76 × 200 mm (100–250 mesh) |

pc |

1 |

– |

3 |

Magnetic Bars |

Φ25 × 156 mm, 10 000 GS |

pc |

3 |

– |

4 |

Pressure Gauge |

Φ60, 0–1 MPa, SUS304 |

pc |

1 |

– |

5 |

Scraper Assembly |

Triple‑blade, PTFE scrapers / SS springs |

set |

1 |

– |

6 |

Tubes & Valves |

Φ25, SUS304 |

set |

1 |

– |

7 |

Stainless Tray |

Custom size (L × W × H) |

pc |

1 |

SUS304 |

8 |

Control Box |

Level, pressure, alarm, control |

pc |

1 |

SUS304 |

9 |

Transfer Capacity |

20 L/min |

– |

– |

working flow |

III. Additional Notes & Precautions

1. Shaft seals, scrapers, and filter elements are consumables.

2. System is intended for single‑slurry, continuous production; frequent formulation change or batch interruption is discouraged.

3. When changing material system, clean lines & magnetic filter and replace key parts (filters), preferably new tubing.

4. Keep pipelines filled with slurry to avoid air/moisture ingress that may cause gelation.

5. Overall Dimensions: L 500 × W 1000 × H 900 mm

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com