products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Pouch Cell Electrolyte Filling Machine

Model Number:

TMAX-ZYJ-200Compliance:

CE CertifiedWarranty:

2 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

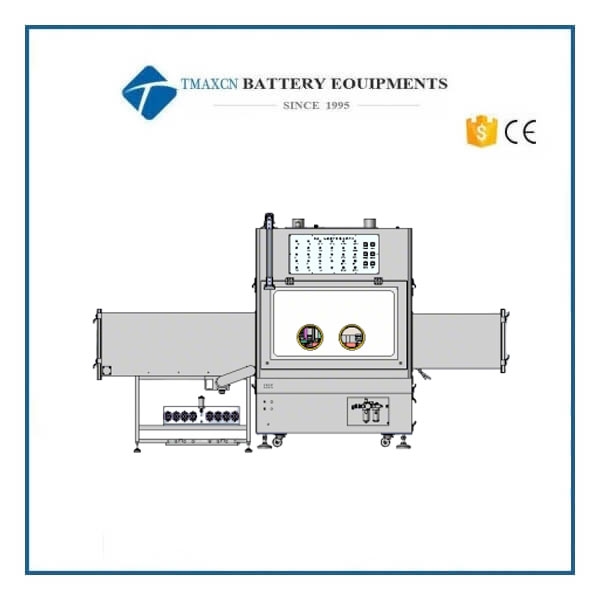

Automatic Pouch Cell Electrolyte Filling Machine

I. Equipment Introduction

1. Applicable for manual loading of pouch cell lithium-ion battery cells (rotary table fixture, one-out-two), normal pressure electrolyte filling, one-time vacuum degassing, vacuum sealing, and manual unloading.

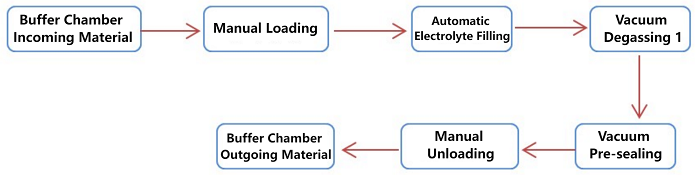

2. This machine consists of manual loading/unloading, automatic electrolyte filling, automatic vacuum degassing, and automatic vacuum pre-sealing. It adopts a rotary table structure to run each process, achieving continuous cyclic operation. The operator places the cell into the fixture for positioning, then presses the foot pedal; the rotary table automatically moves to the next station for electrolyte filling. After filling, it rotates to the vacuum degassing chamber for absorption (time, vacuum pressure, and absorption times adjustable). Once absorption is completed, the table rotates to the vacuum pre-sealing station. After pre-sealing, it returns to the starting position, where the operator removes the sealed cell, reloads, and restarts the cycle operation.

II. Process Flow

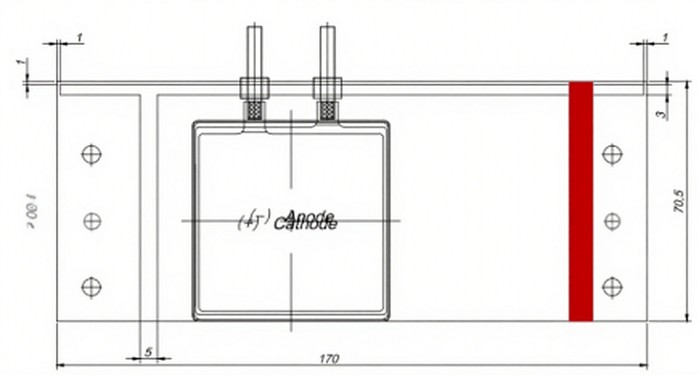

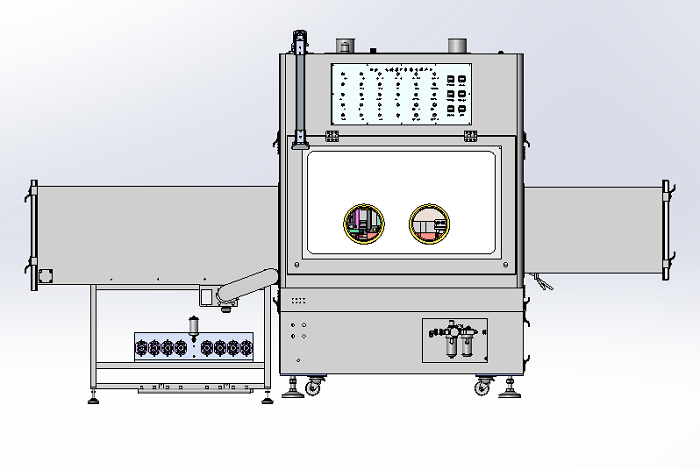

III. Equipment Schematic Diagram

IV. Technical Parameters

Category |

Process Technical Parameters |

Equipment capacity |

Daily output (10H) ≥100 PCS; degassing time ≤360s |

Electrolyte filling accuracy |

≤50 g ±0.1 g (single measurement accuracy) |

Electrolyte pump filling accuracy |

Intelligent adjustable pump, 20 ≤ ±5‰ g (single measurement accuracy) |

Filling method |

Normal pressure filling |

Electrolyte pump service life |

≥ one-year warranty |

Sealing width |

2–5 mm |

Sealing time |

≤99 s (adjustable) |

Sealing head length |

200 ±0.2 mm |

Sealing head material |

Brass (serrated sealing head) |

Sealing temperature |

Normal pressure ~250°C adjustable; control accuracy ±3°C |

Equipment utilization rate |

98% (failure rate caused by equipment; excludes scheduled maintenance, preparation, and material change) |

First pass yield |

99.5% (defects only caused by this machine) |

V. Applicable Specifications

l Applicable for: Blueprint battery (one-out-two fixture)

Remarks for incoming cells: Cells must have no collapsed edges, folded tabs, or irregular gas pockets, and side sealing distance must be consistent.

(Note: The above is for power-type pouch cell lithium-ion batteries. When producing the same type of battery, no fixture replacement is required, only quick adjustment.)

VI. Complete Machine Mechanism

No. |

Mechanism Name |

Quantity |

Description |

1 |

Rotary table fixture |

4 |

1.1 Operator places cell into rotary table fixture (one-out-two). 1.2 Universal fixture, no need to replace when changing models, only quick adjustment required. 1.3 Model changeover time: ≤30 minutes (excluding electrolyte amount adjustment time). 1.4 Machine rotary table and base plate are sealed with stainless steel for easy cleaning and corrosion resistance. |

2 |

Electrolyte filling mechanism |

1 |

2.1 One filling pump head corresponds to one cell. 2.2 Electrolyte anti-drip: filling needle does not drip; liquid collection box installed below the needle. 2.3 No bubbles in filling pipeline. 2.4 Adjustable electrolyte amount parameters. |

3 |

Vacuum degassing mechanism |

1 |

3.1 degassing chamber vacuum ≤ -0.090 MPa (consistent with external vacuum source). 3.2 Number of vacuuming and holding cycles: up to 6 (maximum 6 different vacuum stages configurable). 3.3 Total vacuum degassing duration: Blueprint battery degassing time 6 min. |

4 |

Vacuum sealing mechanism |

1 |

4.1 Pre-sealing chamber vacuum: ≤ -0.090 MPa (consistent with external vacuum source). 4.2 Sealing head configuration: L=200, one set (serrated sealing head). 4.3 Sealing head temperature: room temperature – 250°C adjustable; accuracy ±2°C. 4.4 Sealing head cylinder diameter: 63 mm. 4.5 Sealing head pressure adjustment accuracy: ±0.02 MPa. 4.6 Sealing time: 0–99.9 s configurable. 4.7 Sealing width: 5 mm (to be confirmed based on sample product provided by customer). 4.8 Sealing type: serrated. 4.9 Sealing head cleaning and maintenance: sealing chamber can be flipped 60°. 4.10 After parameters are set, the equipment program automatically detects vacuum pressure, sealing time, sealing temperature; if sealing process is disabled, no sealing will occur. |

5 |

Electrolyte tank system |

1 |

5.1 Two storage tanks: one for degassing (with motor), one for electrolyte filling. 5.2 Tanks placed in sealed dry environment. 5.3 Automatic electrolyte filling. |

6 |

Control system |

1 |

6.1 Internal junction box with sealed design to prevent electrolyte leakage. 6.2 Power-off retention function: absorption box remains pressed down during power outage (prevents overpressure explosion in chamber if cylinder rises); upon power recovery, the system automatically detects previous state and resumes operation. 6.3 Tianmeifu logo, English panel, English HMI, export wooden case packaging. |

7 |

Machine fixed frame |

1 |

7.1 Square tube welded frame, stable operation. 7.2 Feeding warehouse dimensions: W400×H520×L1200 mm; conveyor belt with foot pedal control. 7.3 Material conveying: belt conveyor at feeding, flat conveyor at discharge. 7.4 Discharge warehouse dimensions: W400×H460×L≈800 mm. 7.5 Minimum operating table width: 240 mm (suitable for material boxes ≤220 mm width). |

VII. Standard Configuration

No. |

Name |

Brand |

Remarks |

1 |

Cylinder / Solenoid valve |

AIRTAC |

— |

2 |

Vacuum gauge |

Panasonic |

— |

3 |

Pneumatic parts |

Domestic |

— |

4 |

Linear guide |

HIWIN |

— |

5 |

Ball screw |

HIWIN |

— |

6 |

Linear bearing |

YTP / HRB |

— |

7 |

Servo motor / Driver |

Delta |

— |

8 |

PLC |

Panasonic / Omron |

— |

9 |

Touch screen |

Xinjie / Weintek |

— |

10 |

Stepper motor |

Jianghua Motor / Taiwan |

— |

11 |

AC motor |

Taiwan |

— |

12 |

Temperature control system |

Xinjie / Hanlong |

— |

13 |

Intelligent electrolyte pump |

Dongguan Jiyanda |

— |

14 |

Electrical control system |

Delixi, Chint |

— |

15 |

Electronic scale |

Domestic |

Provided by Party B |

VIII. General Machine Overview and Environmental Requirements

Category |

Specification |

Dimensions |

L×W×H ≈ 1650×1650 (excluding transition conveyor) × 2300 mm |

Weight |

1.5 T |

Floor load capacity |

>500 kg/m² |

Power supply (provided by buyer) |

Voltage: 3-phase AC380V ±10%, 50 Hz; Power: 3 kW; Plug: European standard |

Compressed air (provided by buyer) |

Pressure: 0.5–0.7 MPa (5–7 kgf/cm²); Consumption: <200 L/h; dried, filtered, regulated |

Vacuum (provided by buyer) |

≤ -0.095 MPa; Vacuum gas consumption: <400 L/h |

Dry gas |

Dry gas consumption: <50 m³/h |

Relative humidity (provided by buyer) |

0–90% RH |

Air/Dust (provided by buyer) |

No salty, toxic, or corrosive gases; no conductive dust |

Magnetic field & vibration (provided by buyer) |

No magnetic fields, shocks, or vibrations affecting device operation |

IX. Spare Parts List

No. |

Name |

Specification/Model |

Quantity |

Manufacturer |

1 |

Suction cup |

P10BN |

4 pcs |

Sanxing Jiyan |

2 |

Vacuum tube |

1-inch steel wire hose |

2 m |

— |

3 |

Heating tube |

Φ8×200, 400 W |

2 pcs |

— |

4 |

Temperature sensing wire |

A-100 K2M TEFLON 7/0.2×2 |

2 m |

Minyang |

5 |

Solid state relay |

G3NA-210B (DC5–24) |

2 pcs |

Omron |

6 |

Fuse |

10 A |

5 pcs |

Luke |

7 |

Hex wrench set |

1.5–10 mm |

1 set |

TGK |

8 |

Open-end wrench set |

6–22 mm |

1 set |

— |

9 |

Adjustable wrench |

— |

1 pc |

— |

10 |

Screwdriver |

101 flathead & 101 Phillips |

1 each |

— |

11 |

Toolbox |

— |

1 pc |

— |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com