products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

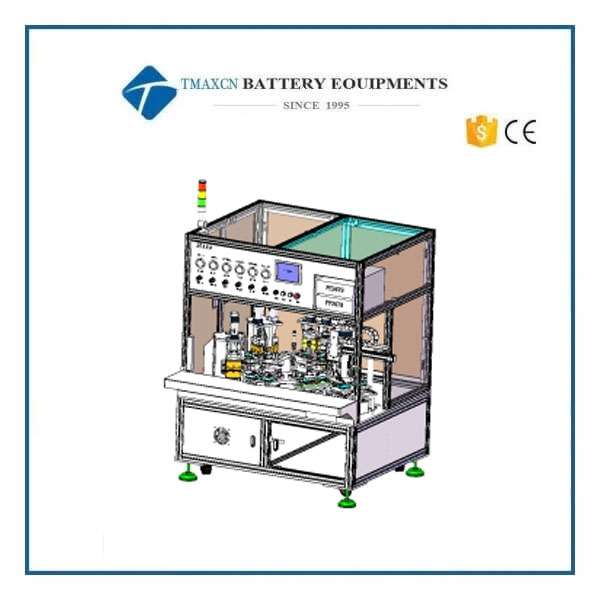

Automatic Pouch Cell Six-Station Top and Side Hot Sealing Machine

Model Number:

TMAX-6DCF-100ACompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5 in 1 Automatic Pouch Cell Top and Side Hot Sealing MachineNext:

Automatic Pouch Cell Dual-Station Top and Side Hot Sealing Machine

Automatic Pouch Cell Six-Station Top and Side Hot Sealing Machine

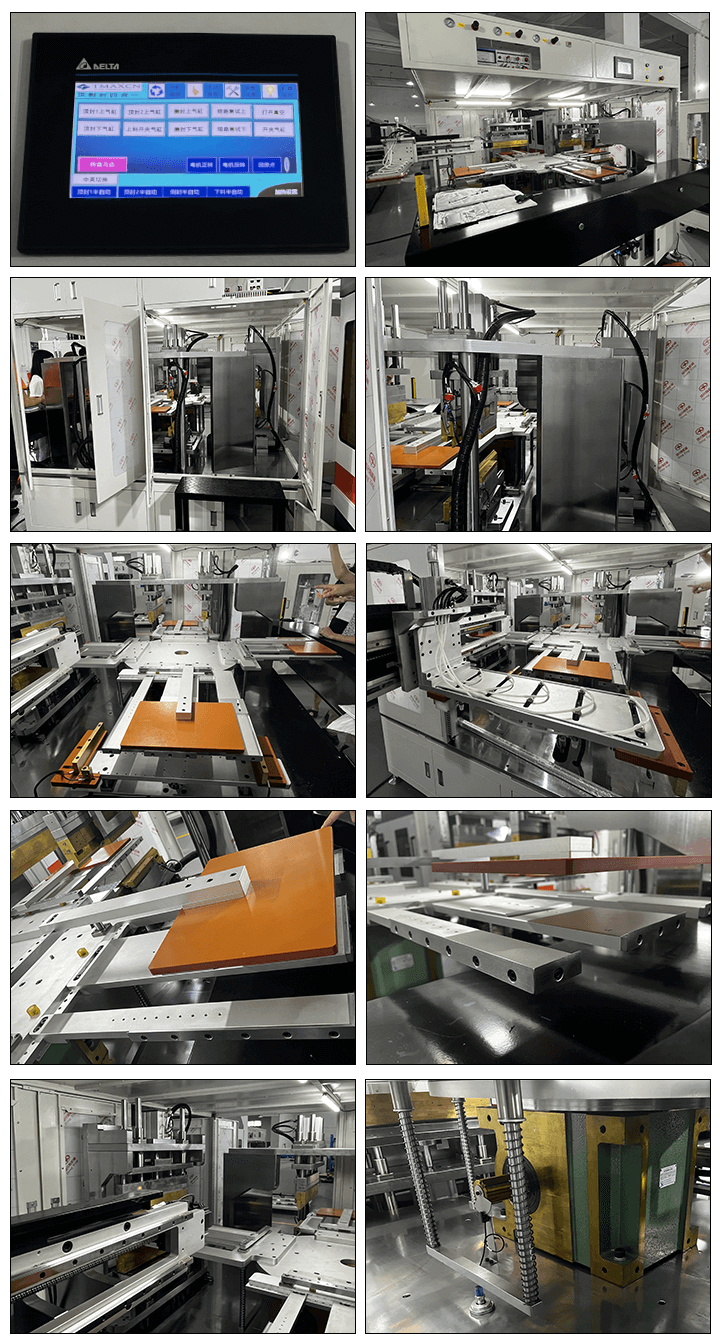

1. Equipment Description

This equipment is mainly used for automatic top sealing (left and right), side heating sealing, edge trimming, flaring, and testing of pouch cell lithium-ion batteries. It is also compatible with certain prismatic cells. The machine operates with a rotary dual-station design.

The workflow includes: loading → left top sealing → right top sealing → side sealing → edge trimming → testing → flaring → unloading.

2. Equipment Schematic Diagram

(For reference only; subject to actual product)

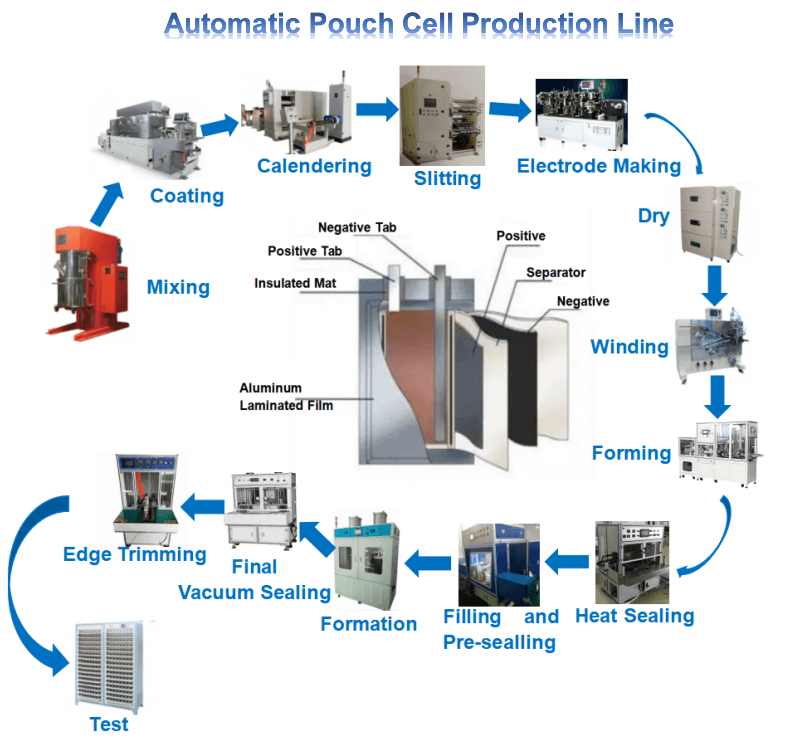

3. Equipment Process Flow

4. Applicable Battery Specifications

L=30—65mm

W1=55-90mm

W=50—90mm

O=5—22mm

Compatible Products:

By changing the fixture, the equipment can adapt to small prismatic cells.

5. Main Technical Parameters

Item |

Specification |

5.1 Equipment Efficiency |

10–14 ppm (depending on sealing parameters and operator skill) |

5.2 Applicable Specifications |

Cell diameter: ∮05–∮22 mm; Cell length: 30–65 mm (main body) |

5.3 Heating Rod Power |

500 W per rod |

5.4 Temperature Control Accuracy |

±3°C |

5.5 Sealing Head Material |

Brass |

5.6 Sealing Head Length |

100 mm |

5.7 Sealing Pressure |

0–0.6 MPa adjustable; pressure control accuracy: ±0.02 MPa |

5.8 Sealing Head Parallelism |

±0.015 mm |

5.9 Cylinder Diameter |

Upper sealing head: Ø40 mm; Lower sealing head: Ø50 mm |

5.10 Pass Rate |

≥98% |

6. Functional Description

l 6.1 Both top and bottom sealing use soft sealing process.

l 6.2 Locating holes are present on the cell fixture, aligned with positioning pins on the rotary table to ensure sealing precision.

l 6.3 Sealing time for top, bottom, and side sealing can be set via the touchscreen.

l 6.4 All sealing operations use pneumatic cylinders; sealing pressure is adjusted via pressure regulating valves on the control panel.

l 6.5 Temperature is controlled by temperature control modules or controllers.

l 6.6 The positioning fixture operates with a one-out-one fixture — one cell is placed per cycle.

l 6.7 The edge trimming station uses SKD11 cutting blades with a single sharpening life exceeding 300,000 cycles; can be resharpened over 10 times.

l 6.8 The testing station uses pneumatic cylinders with probes for inspection.

l 6.9 The flaring station uses a vacuum suction cup in coordination with flaring tools.

7. System Protection Functions

l 7.1 Equipped with an HMI system mounted on the frame for easy operation and debugging.

l 7.2 Equipped with protective covers for safety.

l 7.3 Includes a leakage protection switch and proper grounding to ensure operator safety.

8. Main Components

Component Type |

Brand |

Pneumatic Components |

Airtac / Xingchen |

Motor |

Domestic / Hechuan |

Linear Guide / Ball Screw |

HIWIN / Domestic |

PLC |

Omron / Xinje |

Touchscreen |

Xinje / Weinview |

9. Installation Requirements

l Power Supply: AC220V, 50Hz, Power: 2.5 kW

l Compressed Air: ≥0.6 MPa, Relative Humidity <30% RH

l Vacuum Source: ≤-95 KPa

l Equipment Weight: Approx. 800 kg

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588