products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

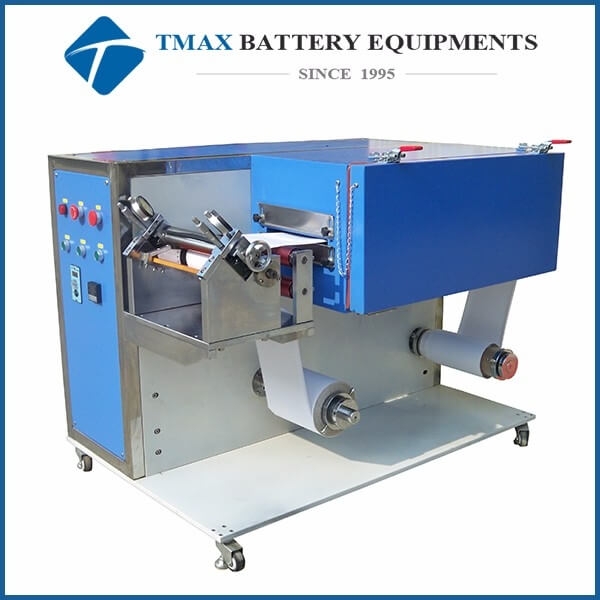

Automatic Roll to Roll Continuous Film Coating Machine with Drying Oven For Battery Electrodes

Model Number:

TMAX-SY300LCompliance:

CE CertifiedWarranty:

1 yearShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Roll to roll Electrode Coating Laminating MachineNext:

200C Max. Automatic Film Coating Machine with Dryer Cover and 140mm Doctor Blade

Automatic Roll to Roll Continuous Film Coating Machine with Drying Oven For Battery Electrodes

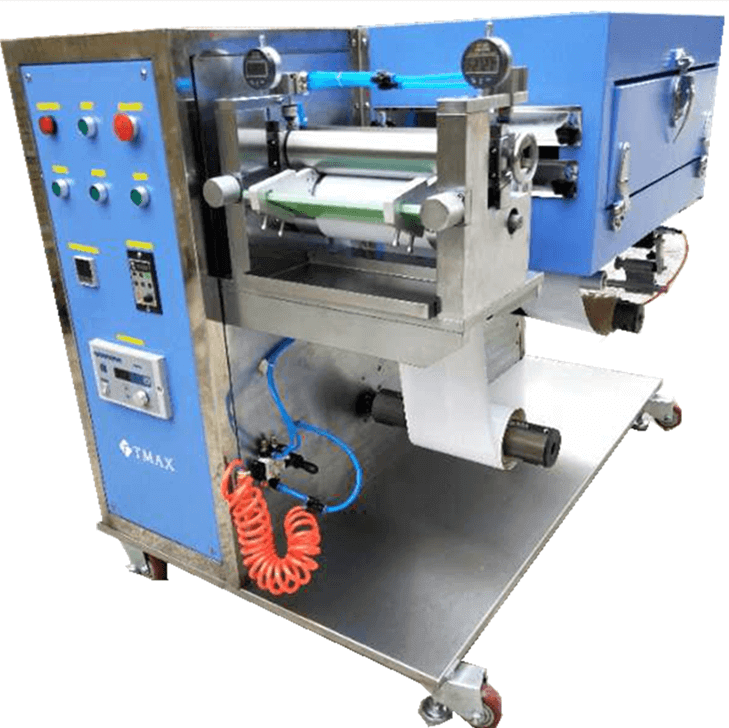

The continuous laboratory coating machine is a three-roller transfer-type coating system, designed for surface coating applications on various substrates. It is particularly suited for the lithium-ion battery industry, offering researchers a user-friendly solution while ensuring coating accuracy and consistency comparable to production standards. With excellent drying performance, it is an ideal choice for R&D and small-scale trials in lithium-ion batteries, supercapacitors, nickel batteries, and other secondary batteries.

Key Features

· Stable web tension control with an auto-correction system to ensure smooth substrate movement.

· Hot-air drying oven with dual-sided air blowing, providing superior drying performance.

· Three-roller transfer coating system, offering a wide coating window.

· Comma blade metering system with a precision adjustment mechanism for high coating accuracy.

· PLC control with touchscreen operation, making the system easy to use.

· Optional NMC solvent recovery and treatment system for enhanced environmental safety.

Technical Specifications

Parameter |

Specification |

Coating Method |

Three-roller transfer-type continuous coating |

Roller Width |

300mm |

Coating Width |

Max 280mm |

Mechanical Speed |

Max 900mm/min |

Oven length |

1 meter |

Coating Accuracy |

±3μm (Edge deviation: ±5μm) |

Coating Thickness |

40-200μm (Depending on slurry) |

Thickness Adjustment |

Manual adjustment |

Unwinding/Rewinding Diameter |

Φ250mm |

Rewinding Accuracy |

±0.5mm |

Tension Control |

Max 60N (Adjustable) |

Dial Indicator Accuracy |

1μm |

Drying Temperature |

Room temperature to 120°C (Adjustable) |

Drying Unit |

Standard hot-air drying system |

Compressed Air |

0.5-0.7Mpa |

Power Supply |

AC 220V / 50Hz |

Max Power |

5KW |

Machine Dimensions |

L1800 × W1200 × H1200mm |

Weight |

Approx. 1T |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com