products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Thermal Sealing for Square Pouch Lithium-ion Cell Top/Side Edges & Pouch Cylindrical Cell Top Edges

Model Number:

TMAX-DCFS-200Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Case Forming Machine for Battery Manufacturing LinesNext:

5 in 1 Automatic Top and Side Hot Sealing Machine for Lithium Pouch Cell

Automatic Thermal Sealing for Square Pouch Lithium-ion Cell Top/Side Edges & Pouch Cylindrical Cell Top Edges

I. Functions and Working Process

l Function:

Performs thermal sealing on the top and side edges of square pouch lithium-ion cells, or top edge sealing for pouch cylindrical cells.

l Working Process:

Place the battery in the battery tray. Press the two control buttons on the front of the operation panel, and the machine will automatically rotate the turntable to move the battery to the sealing position. The upper and lower heat sealing bars will then thermally seal the battery's edge. After maintaining pressure for the set time, the heat sealing bars will retract to their initial positions. When the next battery is loaded, the previously sealed one can be taken out.

If there is no battery in the tray, the corresponding upper and lower heat sealing bars will not activate.

II. Cell Size Specifications

l Standard Cell Size:

No. |

Symbol |

Dimension (mm) |

Diagram |

1 |

L |

100–200 |

|

2 |

W |

100–200 |

|

3 |

H |

3–15 |

III. Basic Parameters

Parameter |

Specification |

Power Supply |

220VAC / 50Hz |

Power Consumption |

4.5 kW |

Heating Rod Power |

500W each |

Compressed Air |

≥0.4 MPa |

Battery Tray Dimensions |

200 × 200 mm |

Applicable Cell Thickness |

≤15 mm |

Sealing Bar Length |

210 mm |

Sealing Bar Width |

Top Sealing: 3.5 mm soft sealing with preheating block for tab Side Sealing:5 mm hard sealing |

Heat Sealing Temperature |

< 250°C, adjustable |

Heat Sealing Speed |

≤400 cycles/hour (depending on process parameters) |

Equipment Weight |

Approx. 330 kg |

Overall Dimensions (L×W×H) |

Approx. 860 × 860 × 1650 mm |

Coating Color |

Customized according to customer requirements |

IV. Process Performance

1. 4-station rotary structure with two sets of heat sealing heads

2. Independent adjustment of top and side sealing temperatures (ambient to 250°C)

3. For square pouch cells, simultaneous top and side sealing is achievable; both soft and hard sealing processes can be realized by replacing sealing strips

4. Touchscreen operation with PLC control

5. Independent adjustment of top and side sealing pressures and cylinder strokes

6. Independent adjustment of top and side sealing times (0–99.9 seconds)

7. A safety light curtain is installed at the front of the machine; if any body part enters during operation, the machine will immediately reset automatically, ensuring safety and reliability

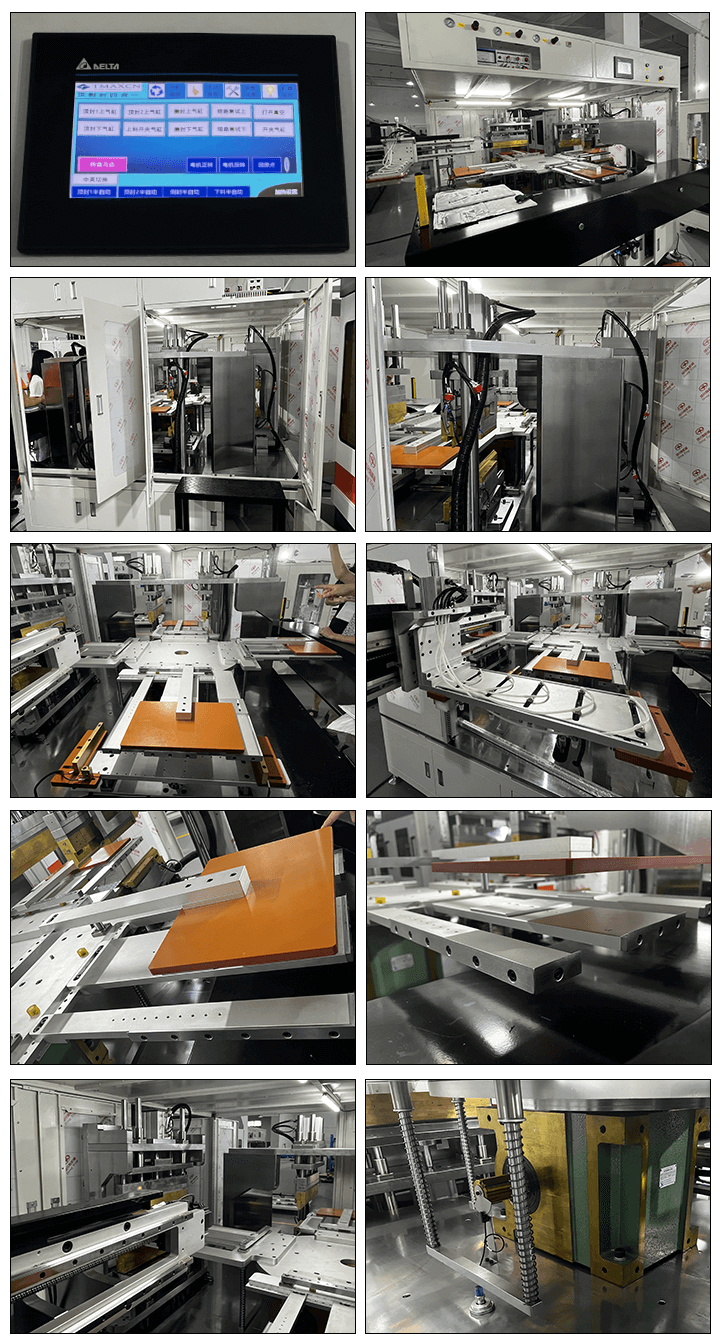

V. Reference Images

VI. Equipment Requirements

1. Overall sheet metal appearance must be precisely finished, no paint loss or damage, seams must be uniform. All screws must be stainless steel hex socket, hinges must be silver stainless steel

2. Acrylic panels must be free from cracking, scratches, or scuffs

3. Aluminum profiles must be free from cracking, scratches, or scuffs

4. Electroplated parts must be rust-free, scratch-free, scuff-free; plating thickness must be above 5μm

5. All machined parts must undergo surface treatment, such as foot support plates, aluminum profile support blocks, and voltage pressing blocks

VII. Equipment Configuration

No. |

Name |

Quantity |

Brand |

Remarks |

1 |

Cylinder |

4 |

AIRTAC |

|

2 |

Solenoid Valve |

4 |

AIRTAC |

|

3 |

PLC |

1 |

Panasonic |

|

4 |

Touchscreen |

1 |

Weintek |

|

5 |

Temperature Controller |

4 |

OMRON |

|

6 |

Pressure Regulating Valve |

1 |

AIRTAC |

|

7 |

Safety Light Curtain |

1 |

LCP |

|

8 |

Electrical Components |

Batch |

CHINT |

|

VIII. Accompanying Documents

No. |

Name |

Quantity |

Unit |

Remarks |

1 |

Operation Manual (Chinese) |

1 |

Set |

|

2 |

Packing List |

1 |

Set |

|

3 |

Complete Front View Diagram |

1 |

Set |

|

4 |

Electrical Schematic Diagram |

1 |

Set |

|

5 |

Main Components Specification List |

1 |

Set |

|

IX. Spare Parts and Accessories List

No. |

Name |

Specification/Model |

Quantity |

Manufacturer |

Remarks |

1 |

Toolbox |

— |

1 set |

— |

|

2 |

Heating Rod |

¢9.8 × 210 |

2 |

— |

|

3 |

Thermocouple |

— |

1 |

— |

|

4 |

Solid State Relay |

— |

2 |

— |

|

5 |

Fuse |

— |

2 |

— |

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com