products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

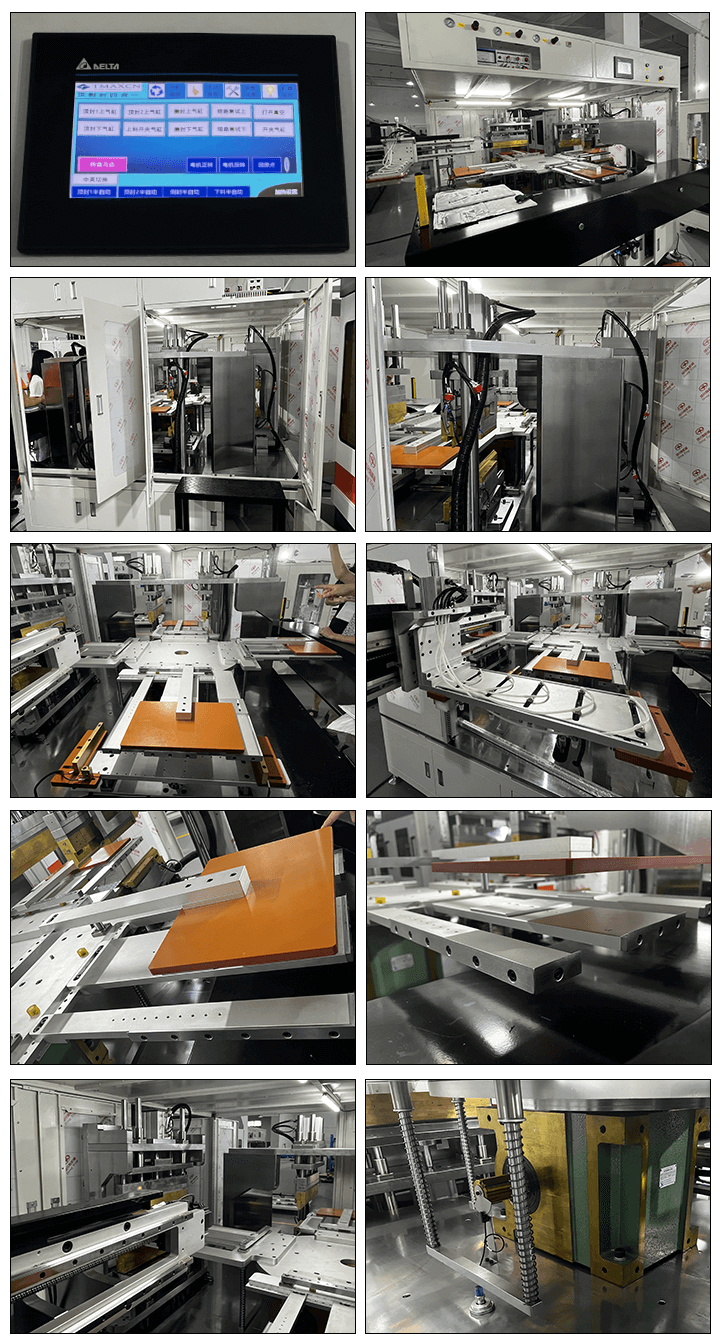

5 in 1 Automatic Top and Side Hot Sealing Machine for Lithium Pouch Cell

Model Number:

TMAX-DCF-200Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Thermal Sealing for Square Pouch Lithium-ion Cell Top/Side Edges & Pouch Cylindrical Cell Top EdgesNext:

Automatic Six-Station Top and Side Hot Sealing Machine for Pouch Cell

5 in 1 Automatic Top and Side Hot Sealing Machine for Lithium Pouch Cell

I. Equipment Technical Parameters:

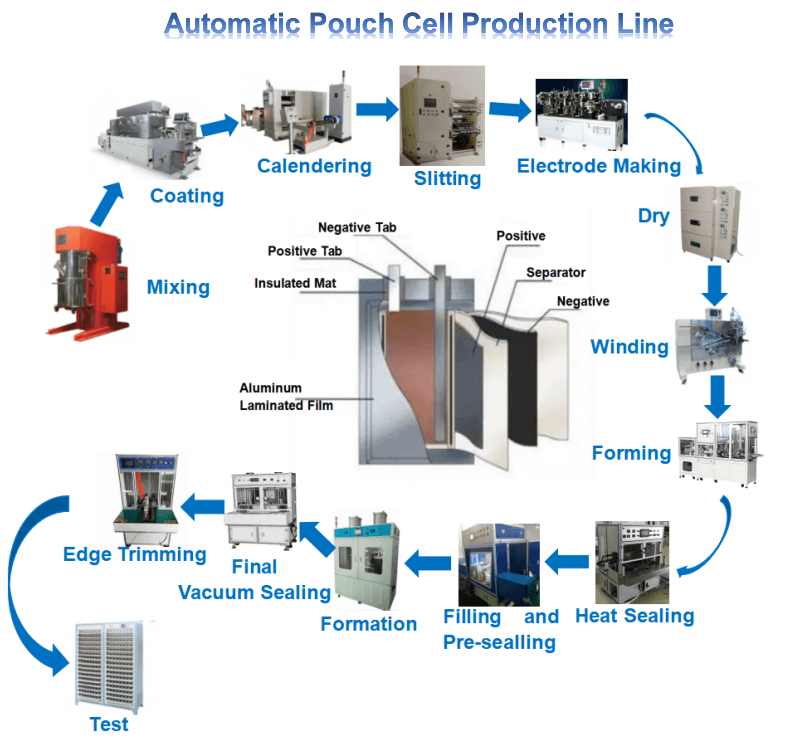

This equipment performs top sealing, side sealing, corner sealing, trimming, and short-circuit testing functions for pouch lithium-ion batteries.

External Dimensions (L×W×H): 1800×1400×1800 mm

II. Cell Size Specifications

Product Applicable Range:

l Length: 60–220 mm

l Width: 50–200 mm

l Thickness: 5–30 mm

III. Equipment Function and Working Principle

This equipment performs top and side sealing for lithium-ion pouch cells. Its rotary table features four stations: loading, top sealing, side sealing, and automatic unloading, enabling automatic completion of top sealing, side sealing, corner sealing, trimming, short-circuit insulation testing, and automatic unloading.

All parameters of the top and side sealing machine are set to process-defined values. When the equipment operates normally and the temperature reaches the set value, confirmation of sealing parameters matching the set values initiates normal production. Operators manually place cells with casings into fixtures; after hands are withdrawn from the fiber optic sensor area, the equipment automatically rotates the turntable to move the battery to the top sealing station. Post top sealing, the turntable rotates the cell to the side sealing station. Upon completion of side sealing, the turntable shifts the cell to the transfer station, where a robotic arm picks it up and transfers it to the corner sealing station. After corner sealing, the cell is moved to the trimming and inspection station for inspection and trimming. Once done, the robotic arm places the cell on the conveyor line, which conveys it out via the logistics line.

The robotic arm automatically unloads tested OK cells onto the conveyor belt, while defective ones are placed into the NG collection box. (Loading, top sealing, side sealing, inspection, unloading, etc., all run synchronously.) This cycle repeats continuously.

(There are two operation modes for the above actions: automatic and manual. Automatic mode can only be activated after the sealing head (hot sealing head) temperature reaches the design value. If the sealing head temperature exceeds the set value by ±5°C, no actions will be performed in either mode.)

IV. Technical Parameters

1. Production Efficiency: ≥5 PPM (depends on actual production parameters)

2. Sealing Heads:

¢ Top Sealing Head Length: ≤200 mm

¢ Top Sealing Width: 2.5–5 mm (soft or hard sealing)

¢ Side Sealing Head Length: ≤250 mm

¢ Side Sealing Width: 5 mm (customizable by customer)

¢ Top and bottom sealing heads are independently temperature-controlled.

¢ Heating rods: ¢9.8×210 mm, 600W, total of 4 rods, uniform heating wire type.

¢ Sealing Head Working Temperature Range: 20°C–220°C, temperature control precision ±3°C.

¢ Flatness of heating blocks at 70°C/10 minutes: less than 0.01 mm

¢ Sealing Head Parallelism: ±0.01 mm

¢ Top and bottom sealing head misalignment precision: less than ±0.1 mm

¢ Sealing Time: adjustable from 0–99 seconds, precision ±0.1 s

¢ Sealing Pressure: adjustable from 0–0.6 MPa, precision ±0.02 MPa

¢ Sealing Sequence: top sealing → side sealing → inspection → unloading

V.Process Performance

1. The top seal (according to customer requirements) and side seal adopt hard sealing technology.

2. The sealing head and heating block are made of H62 brass.

3. The battery fixture is made of aluminum and fixed on the rotating table. The gap between the sealing head and the fixture at each workstation should be less than 0.1mm.

4. Set the top seal, side seal, and corner seal times through the touch screen.

5. The top seal, side seal, and corner seal all use pneumatic transmission. The sealing pressure is adjusted through the top and side sealing pressure regulating valves on the control panel.

6. The sealing temperature is set through the temperature controller on the control panel.

7. The top and side sealing stations are equipped with clamp in place sensors. If there is no fixture placed on the turntable, the sealing head will not work.

8. Testing instrument brand: Yangtze, model: YD9820A

9. Security features:

a. The equipment is enclosed with an aluminum alloy frame and a transparent PCB panel. The control switch is installed on the housing door. When the door is opened, the machine will automatically stop to prevent injury.

The operation station is equipped with a light curtain protection.

VI. Main Component Configuration

● Mechanical Section

1. Rotary Table Mechanism: Includes divider, rotary motor, turntable, and fixtures

2. Top Sealing Assembly: Includes upper top sealing cylinder, lower top sealing structure, insulation block, heating block, and top sealing head

3. Side Sealing Assembly: Includes upper side sealing cylinder, lower side sealing structure, insulation block, heating block, and side sealing head

4. Corner Sealing Assembly: Includes upper and lower sealing mechanisms

5. Trimming Assembly: Includes upper and lower cutting knife mechanisms

6. Testing Assembly: Includes tester and probe mechanism

7. External Frame: Aluminum alloy frame with baked paint and acrylic doors/windows

● Electrical and Key Standard Components Configuration

No. |

Name |

Specification/Model |

Brand |

1 |

PLC |

— |

Panasonic |

2 |

HMI |

— |

Kunlun Tongtai / Weintek |

3 |

Servo Motor |

— |

Inovance |

4 |

Cylinder |

— |

Airtac |

5 |

Solenoid Valve |

— |

Airtac |

6 |

Indexing Divider |

70DF |

Taiwan |

7 |

Reduction Motor |

— |

Domestic LXT |

8 |

Safety Light Curtain |

— |

Leister |

9 |

Temperature Controller |

— |

Omron |

10 |

Electrical Components |

— |

Chint |

● Electrical Spare Parts

Consumable Parts

No. |

Name |

Specification/Model |

Brand |

Unit Price |

1 |

Heating Rod |

¢9.8×210 |

— |

4 pcs |

2 |

Solid State Relay |

— |

Yangming |

2 pcs |

3 |

Thermocouple |

— |

— |

2 pcs |

4 |

Toolbox |

— |

— |

1 pc |

VII.Basic Equipment Parameters

Item |

Description |

Equipment Power Supply |

AC220V ±10% / 50Hz; Power Consumption ≤6.0 kW |

Equipment Air Supply |

0.5–0.7 MPa, 100 L/min |

Floor Load Requirement |

≥500 kg/m² |

Equipment Noise Level |

70 dB at 1 meter distance |

Equipment Weight |

Approx. 1200 kg |

Equipment Dimensions |

1800 mm × 1400 mm × 1800 mm |

Operator Requirement |

One person per machine |

Design Capacity/Speed |

≥3 PPM |

Yield Rate |

≥99% |

Equipment Utilization Rate |

≥95% |

VIII. Accompanying Documents

No. |

Name |

Quantity |

Unit |

Remarks |

1 |

Operation Manual (Chinese version) |

1 |

Set |

|

2 |

Packing List |

1 |

Set |

|

3 |

Electrical Schematic Diagram |

1 |

Set |

|

4 |

Main Components Specification List |

1 |

Set |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com