products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

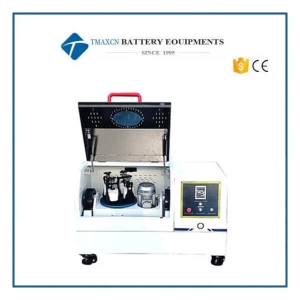

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Jar Ball Mill with 4 Working Stations for Grinding

Jar Ball Mill with 4 Working Stations for Grinding

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Jar Ball Mill with 2 Working Stations with Self-Locking Device

Jar Ball Mill with 2 Working Stations with Self-Locking Device

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Jar Ball Mill with 8 Working Stations

Jar Ball Mill with 8 Working Stations

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Miniature Omni-directional Planetary Ball Mill

Miniature Omni-directional Planetary Ball Mill

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Miniature Omni-directional Planetary Ball Mill

Miniature Omni-directional Planetary Ball Mill

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Lab Jaw Ball Mill Crusher Machine for Primary Crushing

Lab Jaw Ball Mill Crusher Machine for Primary Crushing

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

High-end Small Lab Vertical Square Size Planetary Ball Mill

High-end Small Lab Vertical Square Size Planetary Ball Mill

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Laboratory Grinding Jar Rotating Roller Jar Mill with 2 Working Stations with Self-Locking Device

Laboratory Grinding Jar Rotating Roller Jar Mill with 2 Working Stations with Self-Locking Device

-

30L lab Light horizontal Roller Ball Mill with Stainless Steel Lined

30L lab Light horizontal Roller Ball Mill with Stainless Steel Lined

-

Light Horizontal Roller Jar Mill for Mass Production

Light Horizontal Roller Jar Mill for Mass Production

-

Lab 360C Degree Miniature Omni-directional Planetary Ball Mill

Lab 360C Degree Miniature Omni-directional Planetary Ball Mill

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Mixing and Grinding Planetary Ball Mill Machine

Mixing and Grinding Planetary Ball Mill Machine

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Mini Nano Planetary Ball Mill for Grinding and Mixing

Mini Nano Planetary Ball Mill for Grinding and Mixing

SPECIFICATIONS Overview: 1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production. 2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment). 3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments. 4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Benchtop Vacuum Glove Box with Airlock and vacuum Flange and Gauge

Benchtop Vacuum Glove Box with Airlock and vacuum Flange and Gauge

Single purification unit, PLC control and touch screen operation system. under standard conditions, a standard atmospheric pressure, relative humidity 65%, 99.999% of inert gas source, water oxygen index less than 1 PPM. vacuum glove box functions 1,Closed recirculation: Inert gas recirculate through circulating fan and purifier in the glove box,get rid of water and oxygen continuously. 2,automatic regeneration control:the materials used for getting rid of water and oxygen can be regenerated by program control. 3,automatic cleaning:The replacement of the gas in the glove box is controlled by cleaning valves. 4,The pressure in the box is controlled by PLC.It can be free set within +/-10mbar.If overtop +/-12mbar,automatic protection will start. 5,Vacuum pump will start automatically when the system required. vacuum glove box specifications. 1,Glove box: single cooperation, stainless steel 304, size:1220(L)*750(W)*900(H)mm.Height of underframe is 900mm. 2,Main pipe:stainless steel,valves size DN40. 3,adapter module size: large one: Dia. 360mm,L600mm small one: Dia. 100mm,L300mm. 4,window:tempered glass,thickness 8mm 5,gloves: butyl rubber(imported,7B1532).Diameter of the gloves hole:200mm 6,circulating fan:flow90m3/h,frequency conversion 7, water analyzer :independent display panel;measurement range:0-2000ppm,imported from USA XENTAUR,XDT-PM 8,oxygen analyzer: independent display panel; measurement range:0-10ppm,0-100ppm,0-1000ppm,0-25%,high precision,no drifting,precision 1% 9,organic solvent absorber: installed on the behind,in parallel with main cycle pipe,can absorb the organic solvent first.

-

High-Speed Nano Vibration Planetary Ball Mill for Grinding and Mixing

High-Speed Nano Vibration Planetary Ball Mill for Grinding and Mixing

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com