Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Car battery fabrication line are sophisticated facilities designed for the efficient and precise production of electric vehicle (EV) batteries. These plants typically house various production lines, each dedicated to specific stages of the battery manufacturing process. Here's an overview of the typical production lines found in a lithium battery fabrication plant:

Raw Material Processing Line:

Incoming Materials: Raw materials such as lithium, cobalt, nickel, manganese, aluminum, and electrolyte fluids are received and inspected.

Material Preparation: Raw materials are processed and prepared for the subsequent stages of battery production.

Cathode and Anode Material Production Line:

Coating Process: Thin layers of cathode and anode materials are coated onto aluminum and copper foils, respectively.

Calendaring: The coated foils undergo calendaring to achieve the desired thickness and uniformity.

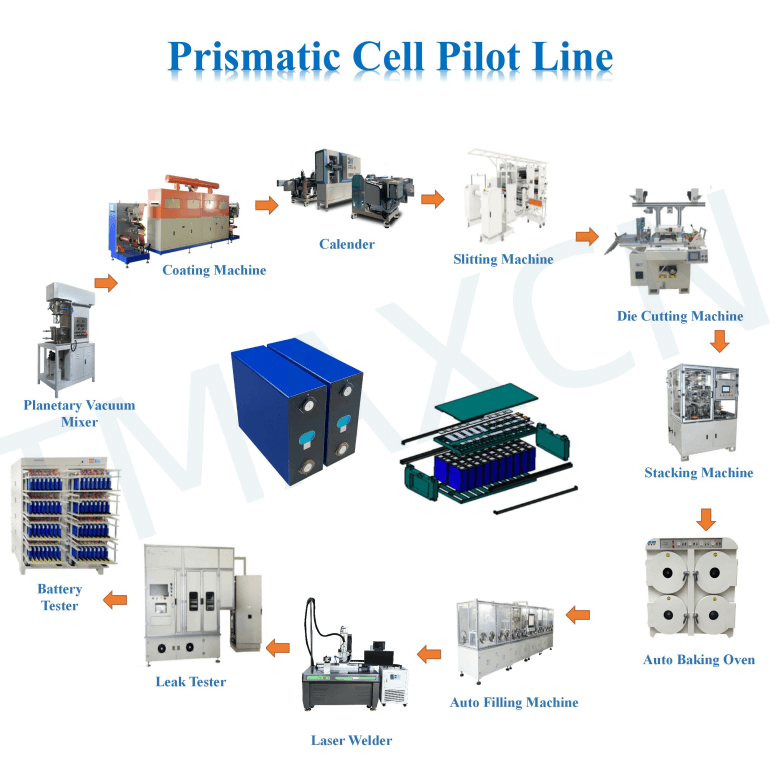

Cell Manufacturing Line:

Assembly: The cathode and anode foils are combined with separators, electrolyte, and other components to assemble individual battery cells.

Formation: Cells undergo a formation process to stabilize their performance and ensure consistent quality.

Testing: Cells are tested for capacity, voltage, and other performance parameters.

Battery Module Assembly Line:

Module Formation: Battery cells are grouped and assembled into modules, which are larger units with higher energy capacity.

Thermal Management: Thermal management systems, including cooling and heating elements, are integrated into the modules.

Battery Pack Assembly Line:

Packaging: Modules are combined, and additional components, such as the Battery Management System (BMS) and safety features, are integrated.

Encapsulation: The entire battery pack is encapsulated, providing protection and structural integrity.

Testing: The complete battery pack undergoes rigorous testing for performance, safety, and quality assurance.

Quality Control and Testing Line:

Automated Testing: Various automated testing stations check the functionality, safety, and performance of individual cells, modules, and battery packs.

Quality Assurance: Strict quality control measures are implemented at each stage to identify and rectify any defects or deviations.

Packaging and Shipping Line:

Packaging: Finished battery packs are packaged securely for transportation.

Logistics: Coordination with logistics partners to ship the battery packs to vehicle assembly plants or other destinations.

Research and Development (R&D) Line:

Innovation and Optimization: lithium battery R&D line facilities within the plant focus on continuous improvement, innovation, and the development of new battery technologies.

Throughout these production lines, automation plays a crucial role in ensuring precision, efficiency, and safety. Advanced technologies, including robotics, AI-driven quality control, and data analytics, contribute to optimizing the manufacturing processes in car battery fabrication plants.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com