Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Revolutionizing Electric Mobility: Cutting-Edge Technologies in EV Car Battery Fabrication Lines

Introduction:

The automotive landscape is undergoing a transformative shift with the widespread adoption of Electric Vehicles (EVs), and at the core of this evolution lies the Electric Vehicle Car Battery Fabrication Line. This intricate system leverages state-of-the-art technologies to manufacture advanced battery systems, playing a pivotal role in the development of sustainable and high-performance EVs. This exploration delves into the intricate details of the latest advancements in EV Car Battery Fabrication Line technologies, highlighting key innovations and their profound impact on the electric mobility landscape.

Key Technological Innovations:

1. Advanced Battery Chemistry:

Modern EVs are benefitting from continuous advancements in battery chemistry. Innovations include the use of lithium iron phosphate (LiFePO4), lithium manganese oxide (LiMn2O4), and lithium cobalt oxide (LiCoO2), each offering unique advantages such as improved energy density, enhanced safety, and prolonged battery life.

2. Intelligent Battery Management Systems (BMS):

Intelligent Battery Management Systems have become the brain of EV batteries. These systems, powered by sophisticated algorithms, constantly monitor and adjust parameters like temperature, voltage, and state of charge. This real-time optimization ensures efficient performance, prevents overcharging, and enhances overall battery lifespan.

3. Robotics and Automation:

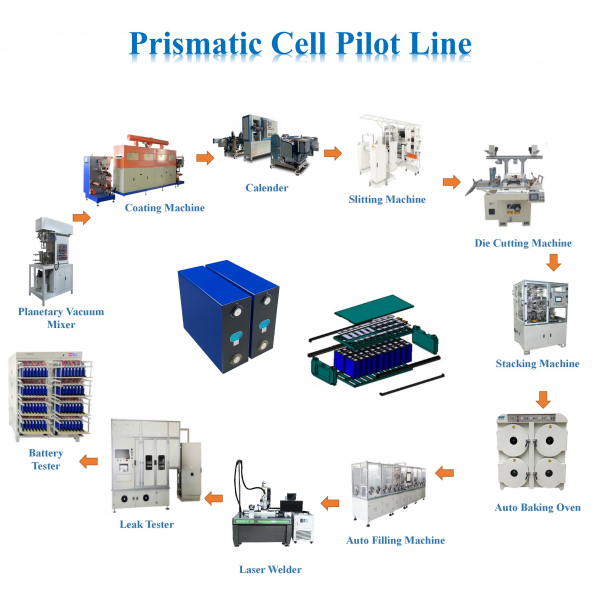

The heart of modern EV Car Battery production Line in their highly automated assembly processes. Robotics and precision automation handle intricate tasks such as electrode stacking, cell winding, and sealing. This not only boosts efficiency but also ensures a consistently high level of quality in each battery produced.

Manufacturing Processes:

1. Nanostructured Electrodes:

Advancements in material science have led to the development of nanostructured electrodes. These electrodes, created through cutting-edge coating technologies, enhance the surface area and conductivity of the materials, contributing to improved energy density and overall battery efficiency.

2. 3D Printing for Battery Components:

Innovative manufacturing processes, including 3D printing, are reshaping the production of battery components. This technique allows for the creation of intricate and customized designs, optimizing the spatial arrangement of electrodes and other components for maximum efficiency.

3. Inline Quality Assurance with AI:

Quality control is seamlessly integrated into the manufacturing process with the assistance of Artificial Intelligence (AI). AI-driven systems analyze real-time data, identifying potential defects or inconsistencies. This proactive approach ensures that only batteries meeting stringent quality standards proceed down the production line.

Future Trends:

1. Ultrafast Charging Solutions:

Researchers are intensively focusing on developing ultrafast charging technologies. These innovations aim to significantly reduce charging times, making EVs even more convenient for consumers. The exploration of advanced electrode materials and energy management systems is crucial to achieving this goal.

2. Solid-State Battery Revolution:

The quest for higher energy density and enhanced safety has led to the exploration of solid-state battery technology. These batteries, free from liquid electrolytes, promise breakthroughs in both performance and safety, potentially reshaping the future of EV power sources.

3. Green and Sustainable Manufacturing:

Sustainability is a driving force in the future of EV Car Battery Manufacturing Line . Manufacturers are actively incorporating eco-friendly practices, focusing on recyclable materials and energy-efficient processes to minimize the environmental footprint of battery production.

Conclusion:

The Electric Vehicle Car Battery Fabrication Line stands at the forefront of technological innovation, steering the automotive industry towards a sustainable and electrified future. As research and development continue to push boundaries, the ongoing evolution of these fabrication lines promises to deliver even more efficient, powerful, and eco-conscious battery solutions, further propelling the widespread adoption of electric mobility.

Note: This detailed exploration is a synthesis of existing knowledge and futuristic projections, reflecting the current trajectory of EV technology.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588