Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

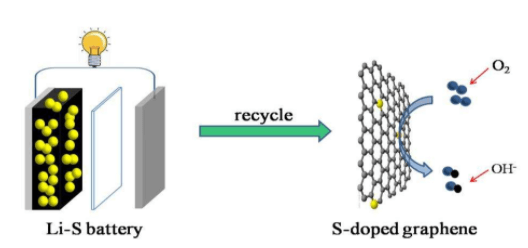

When you need a mobile phone most, are you worried that it won't work? What do you do when you drive an electric car and there is no power in it? For these questions, light lithium sulfur battery can answer for you! Its energy storage capacity is more than twice that of batteries on supermarket shelves, but it usually has no electricity and short service life. Scientists at the joint research center for energy storage research and the Pacific Northwest National Laboratory have found one of the reasons behind this problem.

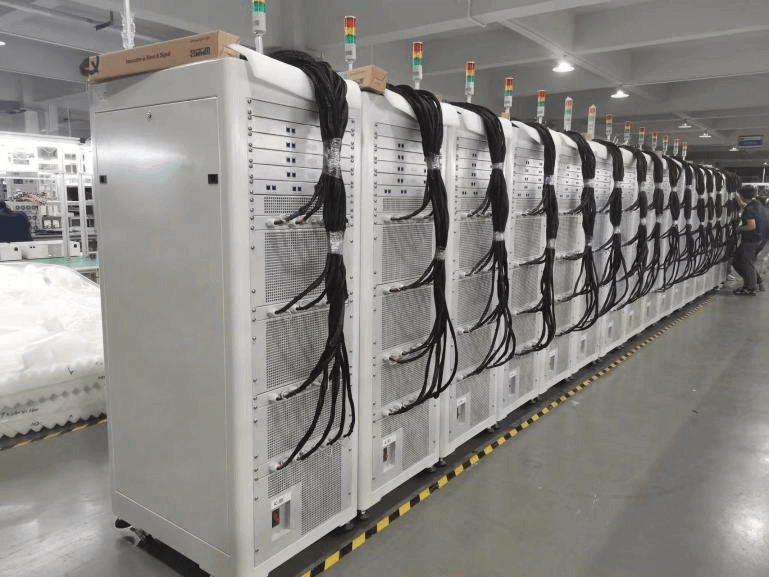

They found that the salt used in the electrolyte in the battery makes a big difference. When a salt called LITFSI lithium trifluoromethylsulfonimide is used as the electrolyte of the battery, lithium battery assembly equipment can test the battery for more than 200 charging and discharging operations. In lithium sulfur battery, lifsi combines lithium and sulfur atoms on the electrode, but it is released quickly. On the contrary, similar electrolytes have stronger binding force to lithium and sulfur atoms, and do not release at all. The performance of the cell decreases rapidly, and the battery has no energy after running for dozens of times. In order to detect the capacity of single battery more accurately, TMAX Equipment can provide 5V 6A 8 channel tester/ 5V 10A/ 5V 100A testing machine etc.for small lab research. For mass testing, you can choose 256 channel or 512 channel charge and discharge tester for lithium battery. We also offer battery pack module tester, for example 100V 100A 8 channel battery pack tester, 100V 200A, 300V 100A battery pack capacity testing device...

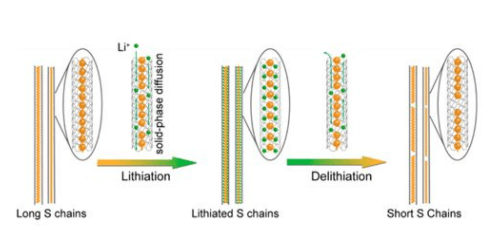

In order to determine the effect of electrolyte on lithium sulfur battery, the research team used LiTFSI and LIFSI to carry out relevant experiments. LiTFSI and LIFSI are very similar electrolytes, only LIFSI contains less carbon and fluorine than LiTFSI. They used the equipment of Environmental Molecular Laboratory to continuously test the energy of battery charge and discharge, and finally studied the electrode. They found that in lithium sulfur batteries using LiTFSI as electrolyte, the lithium atoms produced by lithium battery spot welding machine are bound by sulfur atoms and form lithium sulfide (LISx) on the electrode surface. When LIFSI is used as electrolyte, lithium sulfate (LISOx) is formed. By calculating the compactness of the combination of the two lithium compounds, they found that lithium sulfide is easy to break to release lithium. However, lithium sulfate is difficult to separate, so oxygen in sulfuric acid is the main culprit.

One of the problems with first mover vehicles is that drivers are trapped between charging stations for a long time. This concern led consumers to decide to buy low emission cars. The results of this study add another important factor to the design of high energy lithium sulfur battery.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com