products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

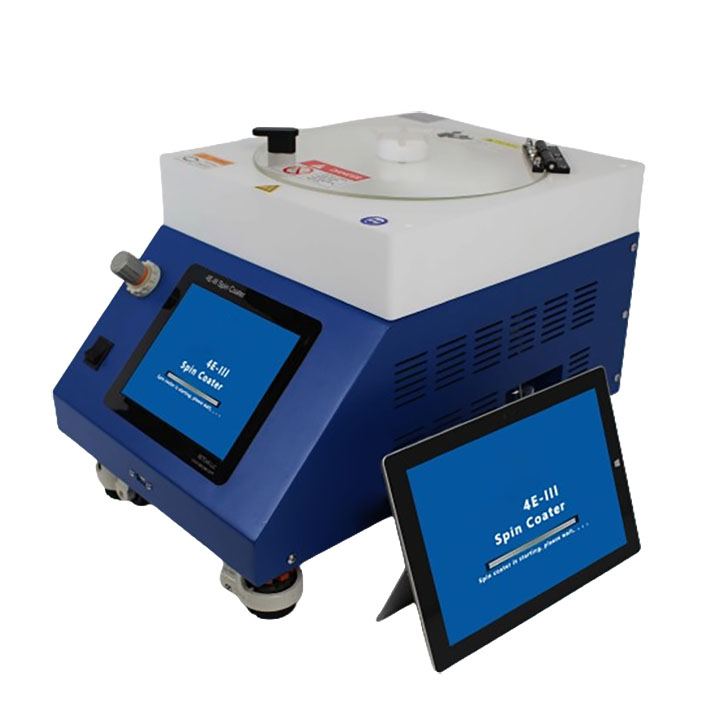

Cheap 200C Rotary Coating Instrument with Vacuum Chunk And Bluetooth Remote Operation for Experimental Research

Model Number:

TMAX-4E-IIICompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Economic Hi-speed 150W Desktop Rotary Coater with Acceleration Adjustable Optional Pipette GunNext:

Lab Table Type Two Channels Injection Pump used with Spin Coater

Cheap 200C Rotary Coating Instrument with Vacuum Chunk And Bluetooth Remote Operation for Experimental Research

Key Features:

1. With heating function: room temperature -200℃

2. With Bluetooth communication function and supporting remote communication software (only supported by KW-4E-I and above models)

3. Can be equipped with 4 channels of automatic glue dispensing and developing function

4. The adsorption force is adjustable, the adsorption force is displayed in real time, and it has leakage recovery function (only supported by KW-4E-III model)

5. The chamber is made of polytetrafluoroethylene PTFE material

6. Spin coating can be reversed and forwarded

7. Motor imported from Germany

Spin Coater Specifications

Glue coating and developing function |

4-way glue development (standard) |

Substrate size |

5-200mm( Standard)/5-600mm (Optional) |

Speed range |

10- 12000RPM( Standard) 11- 10-20000RPM( Optional) |

Acceleration range |

10-30000RPM/S, Adjustable |

Motor speed stability |

±1RPM |

Spin coating uniformity |

±1% |

Heating range |

Room temperature -200℃ |

Heating Speed |

to 100℃ (1S) to 200℃(2S) |

Cooling rate to room temperature |

2 second |

Human machine interface |

8-inch touch screen |

Communication interface |

USB (standard) / RS485 (standard) /Bluetooth (Optional) With Bluetooth communication, free PC communication software, which can remotely control the glue leveling machine |

Turn around |

Support forward and reverse |

Stylus |

Stylus BAMBOO resistance pen (standard) |

Vacuum Pump |

SC-550V |

Set data |

Unlimited groups data,, 10 speeds per group (standard) |

Seconds per period |

0- 10000s |

Storage data |

Unlimited data |

Data protection |

default with power-down protection |

Operating voltage(Spin Coater) |

AC100-250V, single phase, 50/60Hz |

Operating voltage(Pump) |

AC220V(Standard) AC110V(Optional) |

Pumping speed |

≥60L/MIN |

Max vacuum |

-85KPA |

Sound Level |

≤55db |

Spin coater power |

650W |

Pump power |

350W |

Dimensions(Spin Coater) |

340mm(W)X500mm(D)X250mm(H) |

Chamber material |

Overall PTFE material |

Weight(Spin Coater) |

18KG |

Weight(Pump) |

9KG |

Relative humidity |

< 85% |

Ambient temperature |

0-40℃ |

Warranty |

1 year |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com