products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

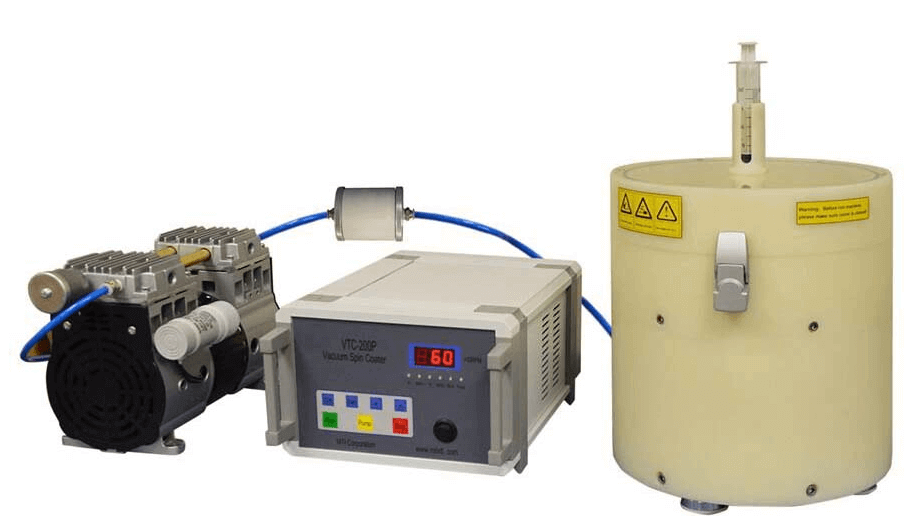

Economic Hi-speed 150W Desktop Rotary Coater with Acceleration Adjustable Optional Pipette Gun

Model Number:

TMAX-VTC-50ACompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

Fujian, China (Mainland)Shipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Four Nozzles Multilayer Spin Coater Unit Supplier For Large Wafer With Optional Spray HeadsNext:

Cheap 200C Rotary Coating Instrument with Vacuum Chunk And Bluetooth Remote Operation for Experimental Research

Economic Hi-speed 150W Desktop Rotary Coater with Acceleration Adjustable Optional Pipette Gun

|

|

|

|

|

Product introduction

The power supply system of VTC-50A rotary coating machine adopts the mode of independent power supply for the motor part and the control part respectively, and the speed regulation system adopts the single-chip microcomputer with high anti-interference to control, making the revolution number in the range of up to 1000-8000RPM is very stable. The film coating machine is provided with two stages at work, respectively, low speed time T1 stage and high speed time T2 stage, the film liquid is gradually dispersed at the low speed stage to complete the glue injection process, and the film liquid is evenly dispersed on the surface of the substrate at the high speed stage to form a film of uniform thickness to complete the process of leveling the glue, before the leveling time is set. When the homogenizing time is over, the machine automatically stops running, and the entire process of coating is over. VTC-50A rotary coating machine is mainly suitable for the use of liquid, colloidal body, movable paste and other film materials, which can provide controllable high-speed revolution in an instant, and quickly make the liquid, colloidal body and other materials uniformly form a film on the substrate. The sample is fixed by the polypropylene sample chuck with grooves. According to the shape and size of the substrate, grooves of different shapes and sizes can be opened on the template of random distribution, which is convenient to use and simple to operate, and has no damage to the substrate. The machine starts quickly, the number of revolutions is stable, which can ensure the uniformity and consistency of the film thickness. In addition, on the installation structure, shock absorption measures are taken to make the noise during operation is very low. The equipment is simple to operate, easy to clean, and small in size, so the equipment is widely used in colleges and universities and scientific research institutes.

Main feature

1.With cast aluminum shell structure and acrylic top cover, the coating process can be clearly observed.

2.Adopted a high anti-interference single chip computer for control, running smoothly at high speed.

3.English operation interface.

4.The sample is fixed with a special polypropylene sample chuck, without vacuum adsorption or bonding; The fixing method is simple, does not deform the substrate and does not have any damage to the substrate. According to the shape and size of the substrate, slots of different shapes and sizes can be opened in the center of the template to fix the substrate.

5.The process of glue injection and blending is controlled in stages to ensure the uniformity of the film layer after coating.

Technical parameter

Product name |

VTC-50A rotary coating machine |

|

Product model |

VTC-50A |

|

Installation condition |

The equipment is required to be used at an altitude of less than 1000m, at a temperature of 25 ° C ±15 ° C, and at a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with water inlet and outlet 2. Electricity: AC220V 50Hz, must be well grounded 3. Gas: No need 4. Workbench: size 600mm×600mm×700mm, bearing capacity 50kg or more 5. Ventilation device: No need |

|

Main parameter |

AC220/110V 50/60Hz |

|

Power:150W |

||

3. Speed: 500rpm-8000rpm |

||

4. Two-step coating program can be set, the speed stability is ±1%, so that the coating is more uniform. SPD1 Rotational speed: 500-8000 RPM valid. T1 time: 1--60s valid. SPD2 Rotational speed: 500-8000 RPM valid. T2 time: 1--60s valid. |

||

5. The diameter of the sample tray is 100mm. |

||

6. The ambient temperature is 5-40℃, the relative humidity is not more than 85%RH, and there is no strong source and corrosive gas around the equipment. |

||

7. Product specifications: Size: 260mm (L) ×380mm (W) ×330mm (H); Weight: 20kg |

|

|

Standard fittings

No. |

Name |

Qty |

Picture link |

1 |

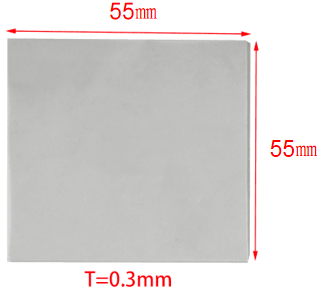

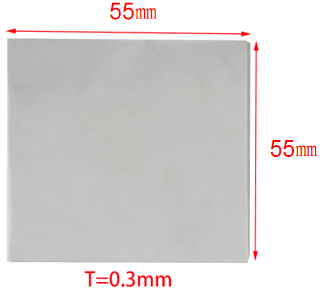

Polypropylene sample chuck (with 55×55㎜ sample slot) |

1Pc

|

|

2 |

Resin base plate |

1Pc

|

|

3 |

Needle tube |

1Pc |

- |

4 |

Template |

5Pcs |

|

Optional fittings

No. |

Name |

Functional category |

Picture link |

1 |

Domestic pipette gun |

(Optional) |

|

2 |

Import pipette gun |

(Optional) |

|

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com