products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Corundum Planetary Grinding Jar with High Chemical Corrosion Resistance

Model Number:

TMAX-CjarDimension(L*W*H):

56*56*70 (mm)Net Weight:

35KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Agate Grinding Jar for High-Purity Material Processing in Planetary Ball MillNext:

Zirconia Planetary Ball Mill Jar with High Hardness and High Strength

Corundum Planetary Grinding Jar with High Chemical Corrosion Resistance

Product introduction

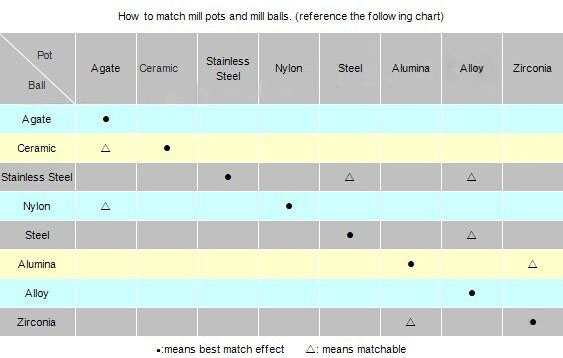

Name of corundum, which comes from India, is a mineralogical name with its hardness nest to diamond. Corundum is mainly used for grinding advanced materials. Corundum jar with zirconia balls .is a best matching way for wear-resistance. Though the corundum has a strong hardness, it is also fragile, please prevent falling to the ground and high strength impact behavior when using it. We can customize various types of vacuum jar according to customer’s needs.

Arc Straight alumina ceramic crucibles’ basic functions

Name: straight alumina crucibles

Chemical Composition Al2O3 ≥ 99

R2O ≤ 0.2

Fe2O3 ≤ 0.1

SiO2 ≤ 0.2

Volume density (g/cm2) ≥ 3.80

Apparent porosity (%) <1

Bending strength (Mpa)> 350

Compressive strength (Mpa)> 12000

Dielectric constant Σ (1MHz) 2

The highest operation temperature (°C) 1800

Best roast container for making powder TV, rare earth materials, precious metals, and roasting high, medium and low ceramic capacitors, NTC, PTC piezoelectric ceramic and lithium cobalt oxide, lithium manganese oxide powder.

Product feature

1. High purity: Al2O3> 99%, good chemical corrosion resistance.

2. Good temperature endurance, long-term use at 1600 °C, 1800 °C short-term.

3. Good rapid thermal shock resistance, not easy to burst.

4. Slip Casting with high density.

Technical Parameter

Parameter of Corundum Mill Jar for Planetary Ball Mill |

||

Model |

Outer Diameter |

Height |

50ml |

56 |

70 |

100ml |

70 |

72 |

250ml |

95 |

88 |

500ml |

106 |

112 |

1000ml |

133 |

131 |

132 |

141 |

|

1500ml |

132 |

173 |

2000ml |

150 |

171 |

Pictures of planetary corundum ball milling jars

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588