products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Cylindrical Cell Electrolyte Filling & Vacuum Degassing Machine

Model Number:

TMAX-ZYDC-25Compliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Cylindrical Cell Electrolyte Filling Machine with Differential-PressureNext:

Two-Layer Single-Door High Vacuum Oven

Cylindrical Cell Electrolyte Filling & Vacuum Degassing Machine

1. Equipment Introduction:

l The cylindrical cell electrolyte filling & vacuum degassing machine is equipment applied to electrolyte filling and vacuum degassing processes for cylindrical cells.

l This equipment adopts a desktop design. The operator places cells into the fixture, presses the start button, and the machine performs automatic filling. After filling is completed, it automatically performs vacuum degassing.

l The equipment can be used inside a dry room, and is an ideal choice for laboratories and research institutes for pouch cell sample production.

2. Workflow:

Operator places the cell into the fixture and presses the start button → Automatic electrolyte filling & vacuum degassing → Operator removes the cell

3. Technical Parameters:

Category |

Process Technical Parameters |

Equipment filling accuracy |

Single filling amount ≤ 5 g ± 0.1 g (multiple fillings can be realized) |

Filling-pump delivery precision |

Pump precision ≤ 5‰; metering ceramic pump |

Filling |

Normal-pressure filling |

Vacuum degassing |

Evacuate the cell to the set vacuum value, up to six segments. Time setting (0–99 s) |

Fixture |

18650 cells, 5 × 5 |

Equipment utilization |

98% (only failures caused by this machine) |

First-pass yield |

99.6% (only defects caused by this machine) |

4. Process Specifications:

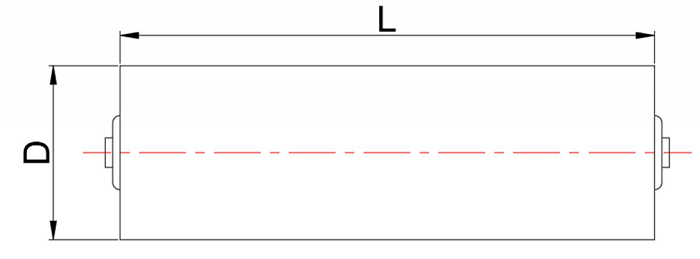

Cell size range:

Outer diameter D compatibility: 18–32

Shoulder height compatibility L: 50–90 L

5. Standard Composition of the Whole Machine:

No. |

Mechanism Name |

Qty. |

Description |

1 |

Fixture |

1 |

a) Place 18650 cells on the fixture in a 5 × 5 layout. b) When changing models, only the fixture needs to be replaced. c) The fixture is equipped with dowel pins for precise positioning. |

2 |

Filling mechanism |

1 |

a) Y-axis of filling adopts a module for position movement; spacing and number of fillings can be set. b) Z-axis of filling adopts a cylinder. c) Filling nozzle material: SUS316. |

3 |

Vacuum degassing |

1 |

a) Perform vacuum degassing on the cell after filling (time adjustable). b) Vacuum can be controlled ≤ −90 kPa. c) Pressure-holding time and cycles ≤ 6. d) Equipped with analog vacuum gauge (vacuum set on touchscreen). e) Vacuum leakage per minute ≤ −3 kPa. f) With power-off / air-loss protection. |

4 |

Filling pump (metering pump) |

1 |

a) Filling amount adjusted by micrometer, simple and convenient. b) Precision ceramic valve with reciprocating rotary motion. c) Static seals: EPDM. d) Ceramic pump core material: alumina, wear-resistant. e) Filling accuracy: ≤ ±5‰ g. f) Single maximum filling amount: 5 g, multiple fillings can be realized. |

5 |

Electrolyte tank system |

1 |

a) Equipped with two tanks: storage tank and filling tank. b) Automatic liquid feeding. c) Storage tank has degassing function—rotating while vacuuming; after bubble removal, flows into the filling tank. d) Inlet equipped with filter screen. e) Storage tank low-material alarm. f) Filling tank low-material alarm causes machine stop. g) Tank material: SUS316. h) Seals: corrosion-resistant (EPDM). Each storage tank capacity ≥ 2 L; each storage tank must be installed with 4 level sensors, to detect level status. During liquid feeding, if the level does not change, the equipment shall alarm. |

6 |

Control system |

1 |

Controlled by industrial PC and PLC for the whole machine; the sealing head is controlled by a temperature-control module, ensuring optimal one-pass result. |

6. Standard Configuration:

No. |

Name |

Brand |

Remarks |

1 |

Pneumatic components |

AIRTAC / Domestic |

|

2 |

Linear guide |

HIWIN |

|

3 |

Ball screw |

HIWIN |

|

4 |

Linear bearing |

YTP / HRB |

|

5 |

Servo motor / driver |

Delta |

|

6 |

PLC |

XINJE |

|

7 |

Touchscreen |

XINJE |

|

8 |

Stepper motor |

Jianghua Motor |

|

9 |

AC motor |

Weibang Motor |

|

10 |

Temperature-control system |

XINJE |

|

11 |

One-out-one electronic filling pump |

Dongguan Jiyanda |

|

7. Overview of Whole Machine & Environmental Requirements:

Category |

Specification |

Overall dimensions |

L × W × H ≈ 550 × 800 × 650 mm |

Weight |

60 kg |

Power supply (by Buyer) |

Voltage: AC220V ±10%, 50 Hz; Power: 3 kW |

Compressed air (by Buyer) |

Pressure: 0.5–0.7 MPa (5–7 kgf/cm²); Usage: 3 L/s; dried, filtered, regulated |

Vacuum (by Buyer) |

≤ −0.095 MPa; 2 L/s |

Relative humidity (by Buyer) |

0–90% RH |

Air / Dust (by Buyer) |

No saline gas, toxic or corrosive gases; no conductive dust |

Magnetic field & vibration (by Buyer) |

No magnetic field affecting the device; no shocks or vibration |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com