products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

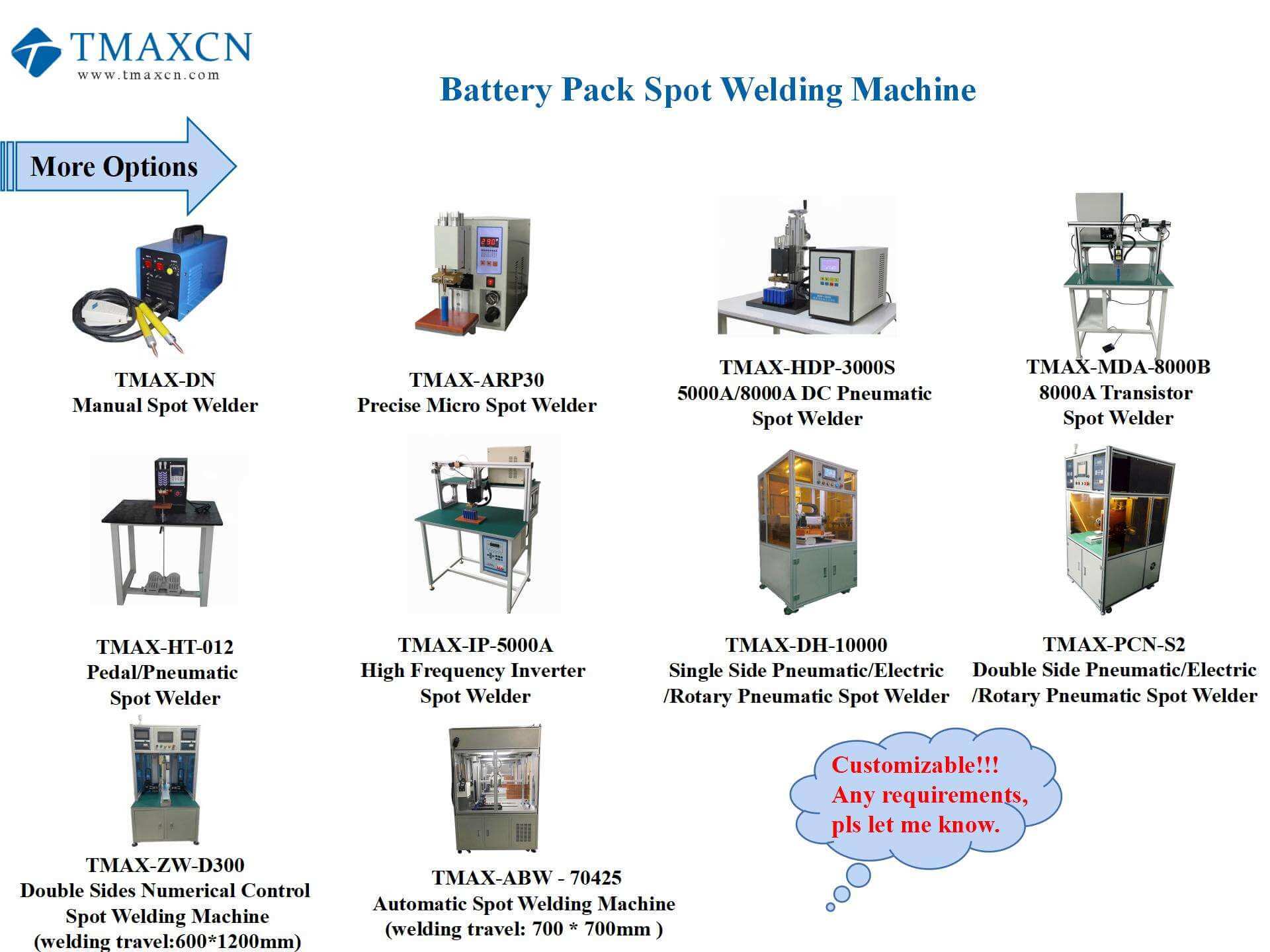

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Double Side Spot Welder for Lifepo4 Green Battery/E-Vehicles/Electric Scooters Battery Module Welding

Model Number:

TMAX-ZW-D300Type:

AutomaticInput Power:

50KW(max)Compliance:

CE CertifiedWarranty:

2 Year limited warranty with lifetime supportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Single Side 5000A/8000A Automatic Spot Welding Machine with Rotary Head with Host Computer Program for EV/ Electric Bike/Power Battery MakingNext:

Single-side Rotary Welding Head Automatic Numerical Control Spot Welding Machine for Storageable NCM Lithium Battery Module Welding

Double Side Spot Welder for Lifepo4 Green Battery/E-Vehicles/Electric Scooters Battery Module Welding

Equipment Introduction

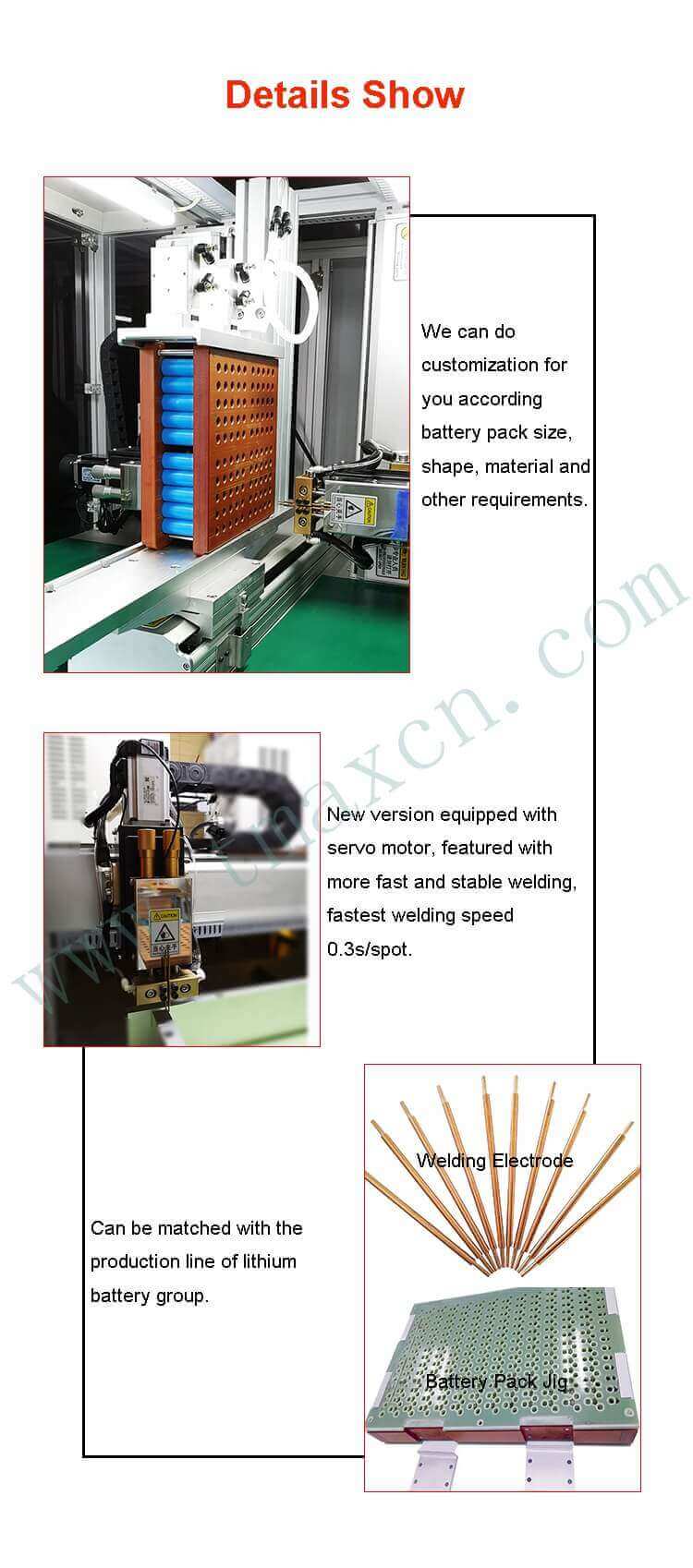

It is suitable for electric vehicle battery pack, automobile battery module, street lamp battery, balance car battery pack, scooter battery pack, mobile power supply, startup battery pack module, power tool battery pack, notebook battery pack, etc! We provide a full series of Energy Storage Battery Assembly for different customers.

Features

1. Support breakpoint start, support automatic start and manual start mode conversion.

2. Simple programming, support any point programming and array programming, can realize jump spot

welding, single point, double point mode fast switching, spot welding path optimization, improve efficiency, local disk can store 99 groups of programming files, USB interface can import graphics.

3. The spot welding head takes the center point of two welding pins as the circle center, and the angle is continuously adjustable, which is suitable for spot welding of various special-shaped split connection pieces.

4. The system is divided into operator, administrator, super user and so on. It is convenient to use, manage and maintain butt welding machine.

5. The inverter DC welding power supply has the advantages of stable performance, fast welding speed, constant current working mode and elimination of unstable factors of welding current for a long time.

6. With welding current monitoring system, it can monitor welding current in real time.

7. Spot welding power supply has the function of false welding alarm, which can directly communicate with the motion controller. It can record the false welding position and warn the replacement of welding pin.

8. The welding efficiency is about 8 times that of manual welding, high stability, labor saving and time cost saving.

Specifications

Power supply |

3 phase~380V±10%/50Hz±10%, |

Rated power |

50KW(max) |

Z1,Z2 Travel Length |

0-600mm(max) |

Y Travel Length |

0-1200mm(max) |

X Travel Length |

0-40mm |

W Shaft angle |

0 |

Welding speed |

0.35 S/point;1800-3600PCS/h |

Maximum speed of motor transmission |

1500mm/s |

Maximum load cell (32650) |

512 pcs |

Number of file groups that can be stored |

99 |

operating system |

Industrial computer + man machine picture |

Transmission mode |

Servo motor + TBI screw + linear guide rail |

Spindle electrode |

Letron servo motor |

Spot welding head |

Letron servo motor |

Angle adjustment |

Closed loop motor |

Cooling mode |

forced air cooling |

Nickel sheet material |

Nickel plated steel or pure nickel |

Thickness of Welded Nickel Strip |

0.1 mm-0.3 mm; (above 0.2 mm slot with bump) |

External dimension (mm) |

1800L*1100W*2000H |

Repeat positioning accuracy |

±0.02mm |

Weight |

600kg |

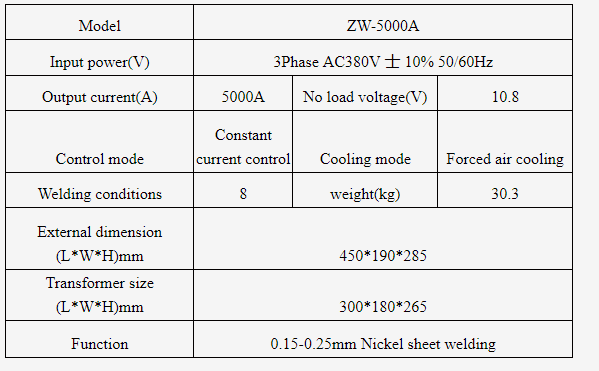

Technical parameters of welding power supply

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com