products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : 8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

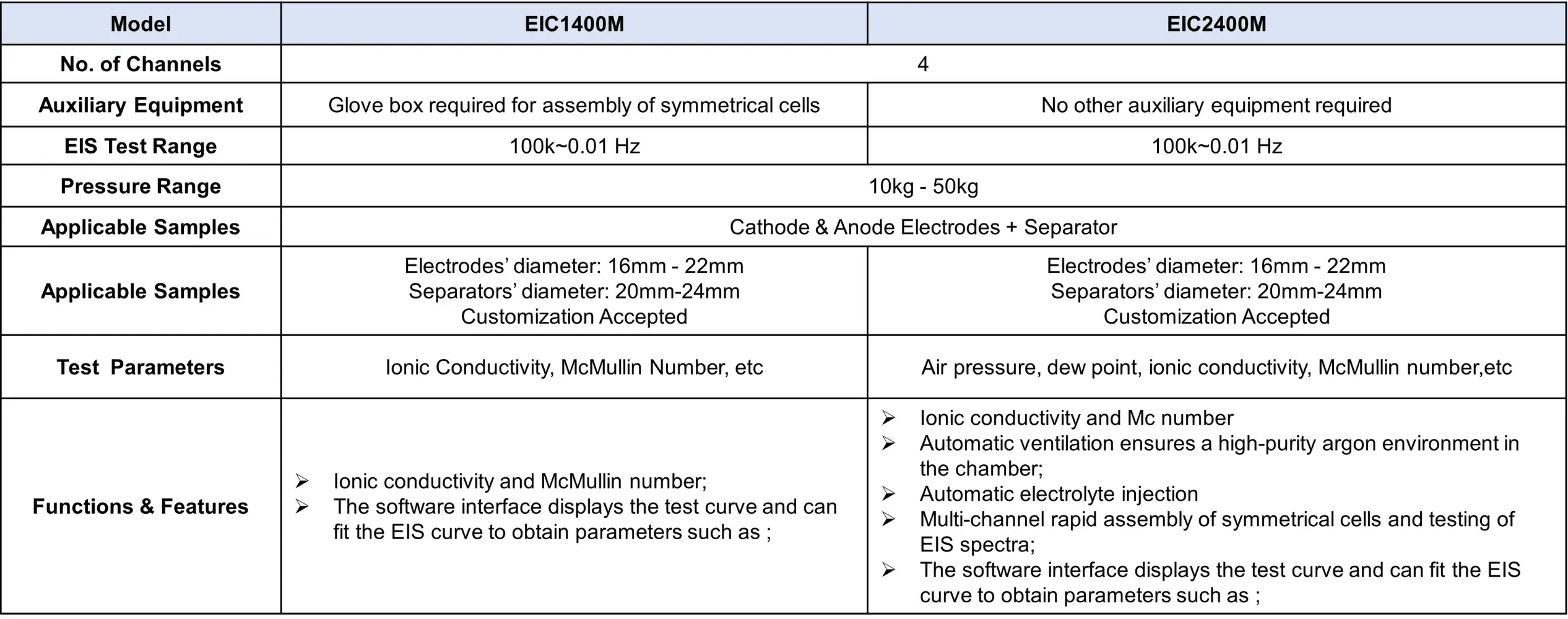

Electrode Tortuosity Tester & Separator Ion Conductivity Tester

Model Number:

TMAX-EICCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : 8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lithium Battery Slurry Resistance TesterNext:

Lithium Battery Electrode Sheet Resistance Tester

Electrode Tortuosity Tester & Separator Ion Conductivity Tester

Characteristic

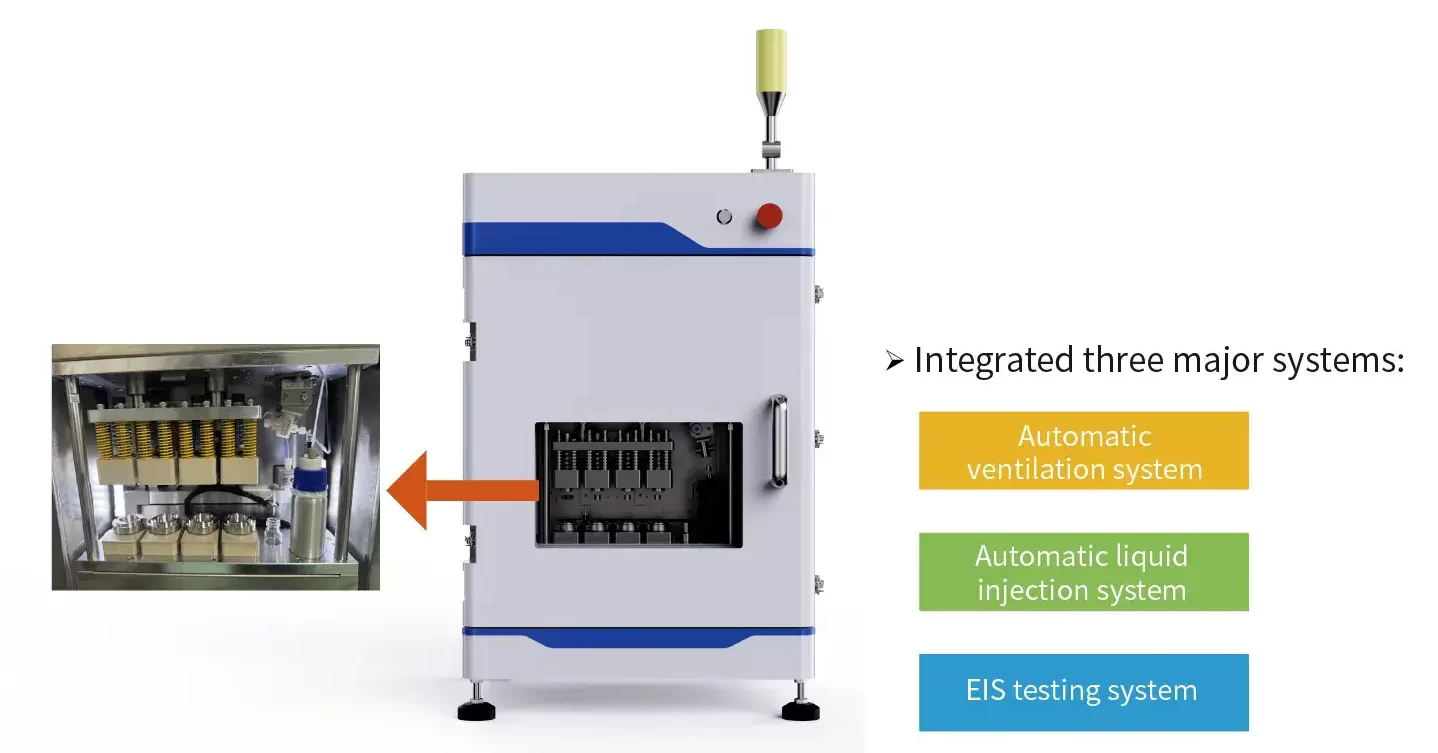

1. Calculate the tortuosity of the electrode by testing the EIS of the battery with symmetrical electrodes.

2. Simple assembly, automated testing and analysis, simplified operating steps, and improved testing efficiency.

3. Four-channel synchronous test.

4. McMullin Number and Tortuosity Measurement

Applications

1. Electrode tortuosity test

2. Separator ion conductivity test

Description

1. Creative Solution One

1.1 Creative Solution:

1) Calculate the MacMullin number of the electrode by testing the EIS of the symmetric cell.

2) Simplify assembly, automate testing and analysis processes, streamline operation steps,and enhance testing efficiency.

3) Synchronous testing across four channels.

1.2 Testing Principle:

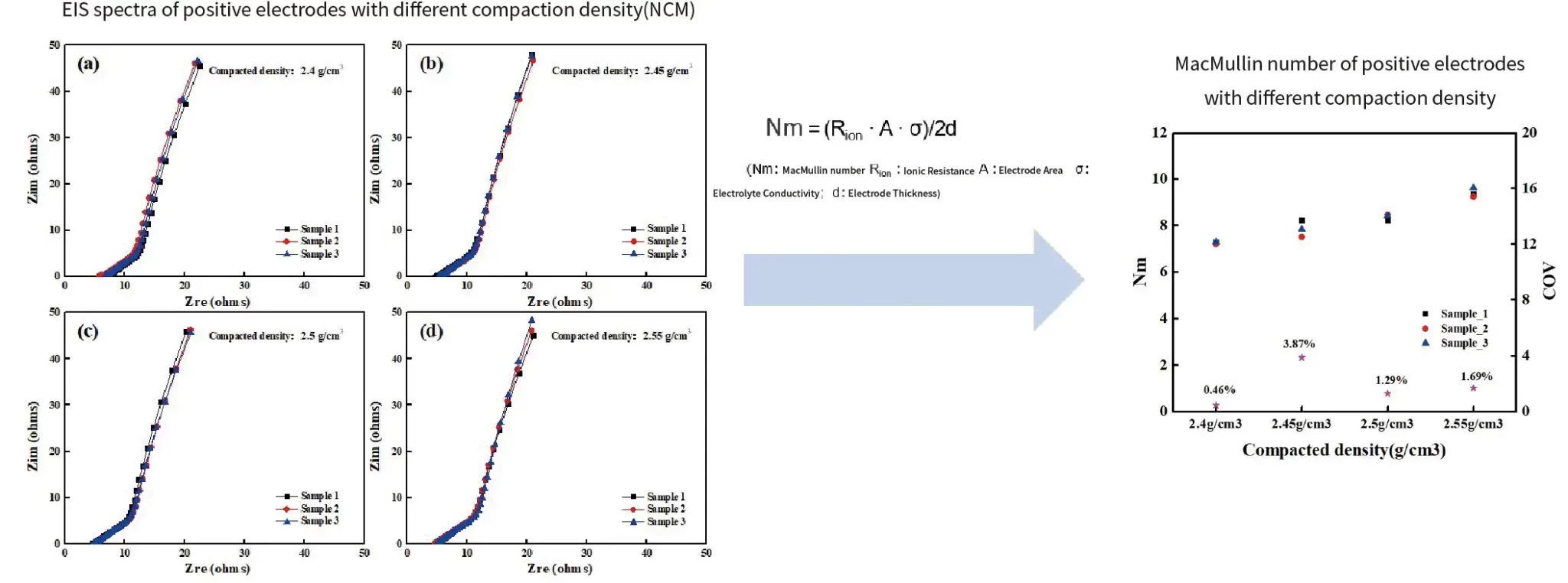

2) As shown in the figure below, low-frequency segments of the EIS spectrum separately. The diference between the intersection of the fitting curves and the X-axis multiplied by 3 is the ionic resistance of the electrode coating.

3) Using the following formula, the MacMulin number can be calculated, This allows for the pre-evaluation of the electrochemica performance of the electrode after it is assembled into a cell. Therefore, characterization and compaison ofthe ionic conductivity of the electrode coating are particularly important.

Application Cases

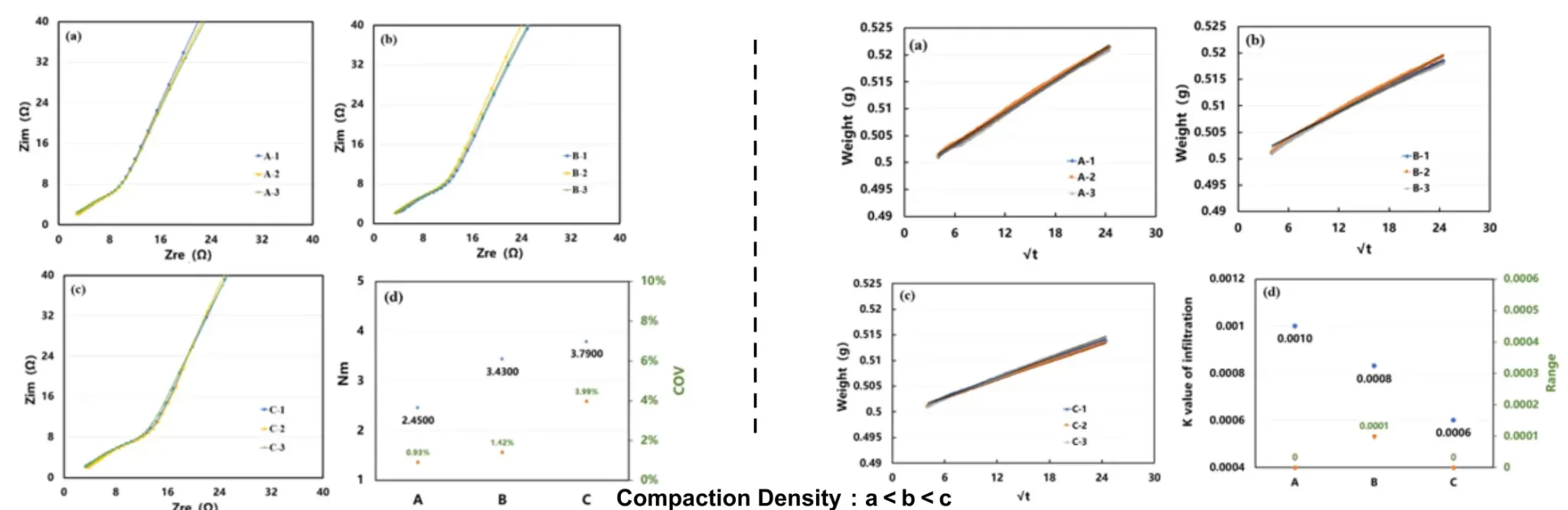

Case 1. Different compaction density of cathode electrodes

Summary:

1) The consistency of ElS testing for symmetric battery of electrodes is generally good.

2) Within a certain range of compaction density, as the compaction increases, the ionic resistance/MacMullin numb also increases.

Case 2. Different compaction density of anode electrodes

Summary:

1) The consistency of ElS testing for symmetric battery of electrodes is generally good.

2) Within a certain range of compaction density, as the compaction increases, the ionic resistance/MacMullin numb also increases.

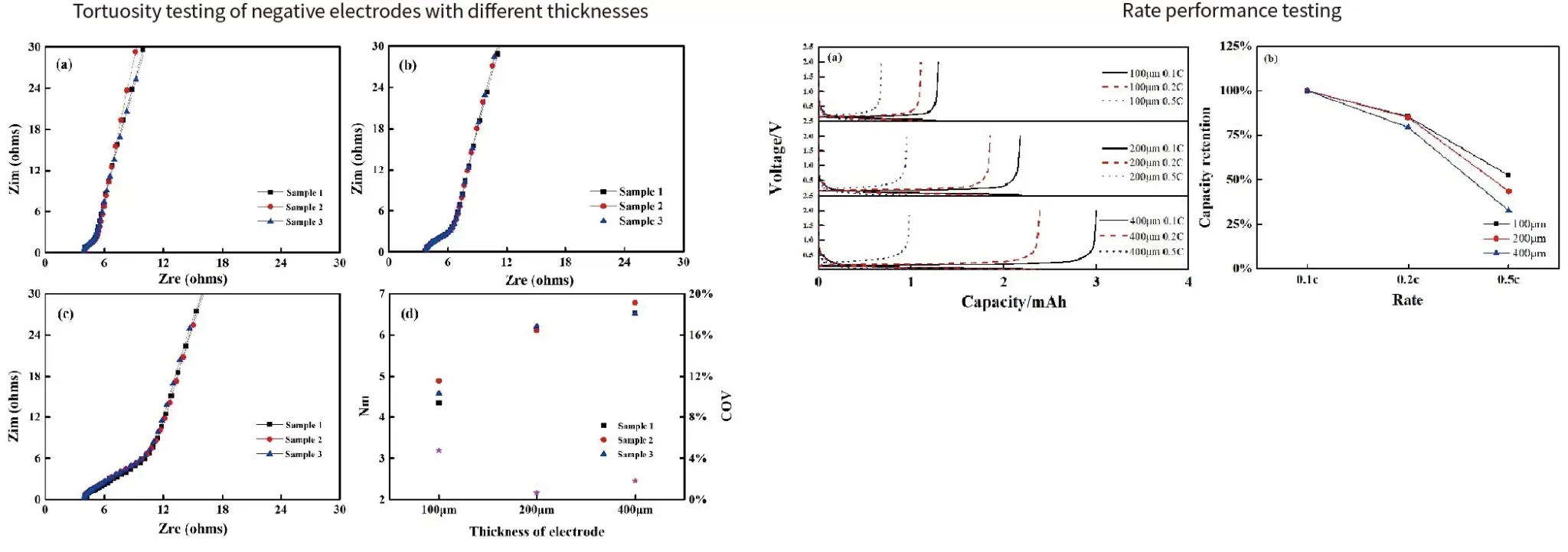

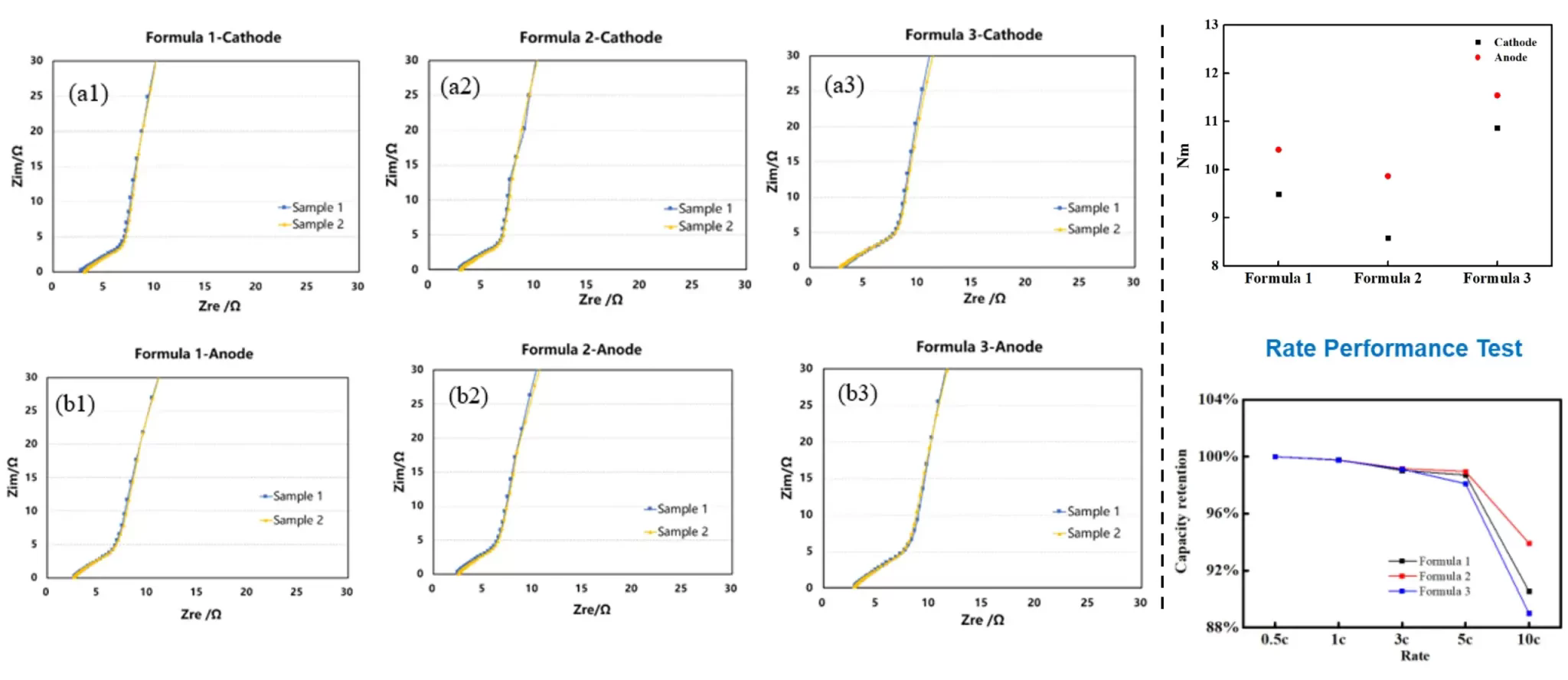

Case 3. The correlation between electrode tortuosity and electrochemical performance(Gr anode electrodes of different thicknesses)

Summary:

1) As the thickness of the electrode increases, its tortuosity also increases, However, the rate performance of the battery decreases with increasing thickness.

2) This indicates that the rate performance of the battery decreases with increasing tortuosity. There is a certain correlation between electrode tortuosity and rate performance of battery.

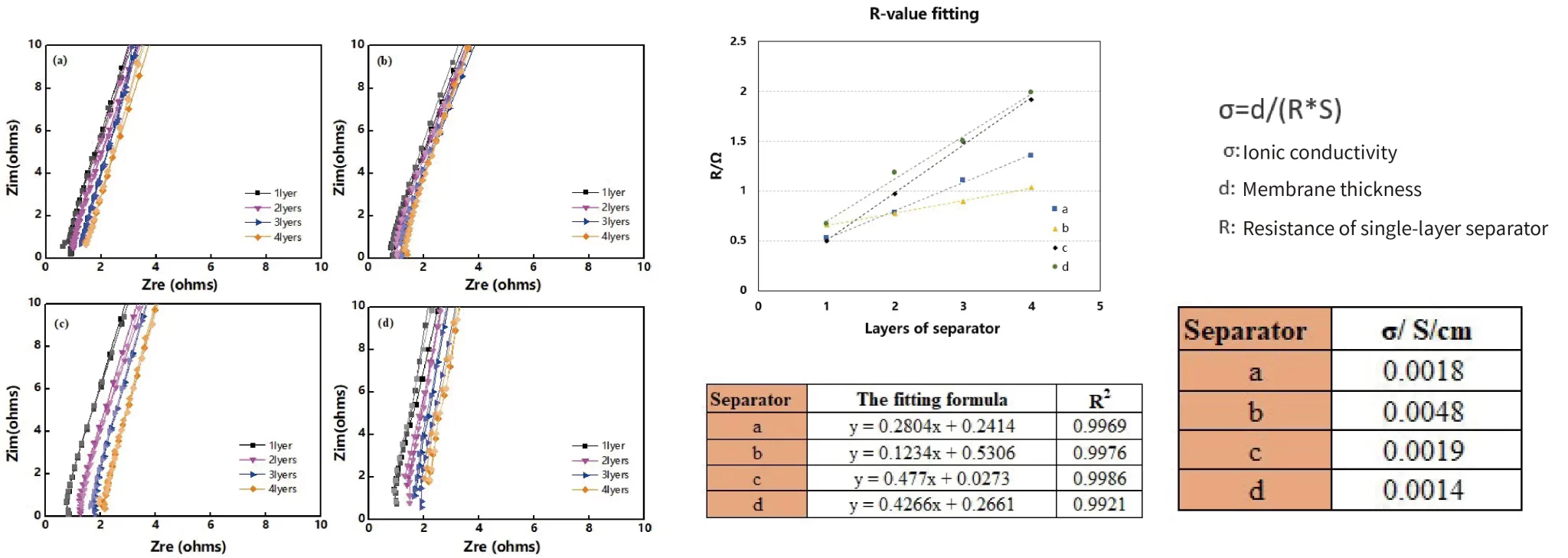

Case 4. Different coated separators(Ionic conductivity testing of four different coated separators)

Summary:

1) Test the EIS of 1-4 layers of separators to obtain R1, R2, R3, R4.

2) Plot a curve with the number of separator layers as the x-axis and separator resistance as the y-axis. Calculate the slope and linear fitting degree of the curve, with the linear fitting degree ≥0.99.

3) Calculate the separator ionic conductivity according to the formula.

Case 5. Correlation between the tortuosity of the electrode and its electrochemical performance in different electrolytes

Summary:

1) MacMullin number Ranking: Formula 2< Formula 1< Formula 3

2) Capacity retenuation Ranking(10C): Formula 2(93.92%) > Formula 1(90.55%)> Formula 3(89%)

Case 6. Tortuosity & Wettability of LFP Cathodes with Different Compaction Densities

Summary:

1) Electrode with poorer wettability exhibit greater tortuosity.

2) As compaction density increases, electrolyte absorption declines, hindering permeation and lithium-ion migration, which elevates ion transport resistance and electrode tortuosity.

Specifications

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com