products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

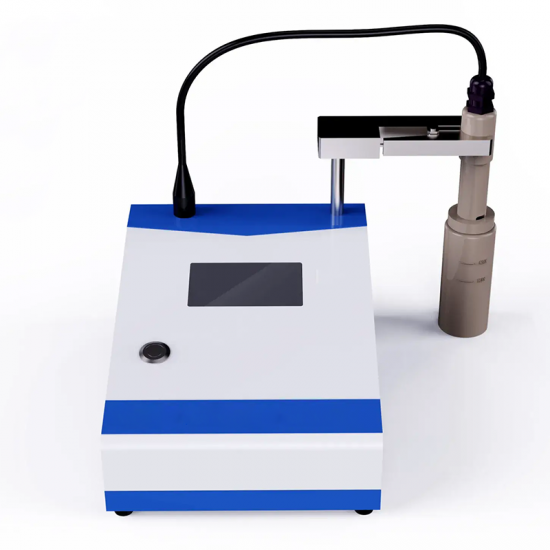

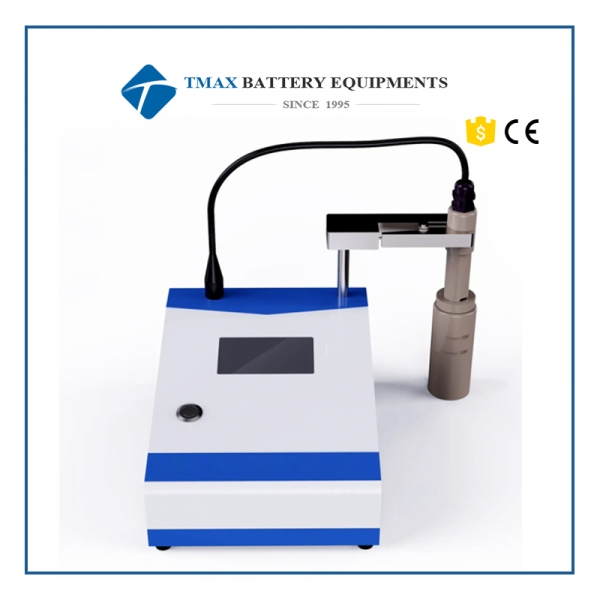

Lithium Battery Slurry Resistance Tester

Model Number:

TMAX-BSR2300Compliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Single Particle Force Properties Test SystemNext:

Electrode Tortuosity Tester & Separator Ion Conductivity Tester

Lithium Battery Slurry Resistance Tester

Introduction

TMAX-BSR2300 use the upper, middle and lower three pairs of electrodes to test the resistivity of the slurry at different vertical heights, evaluate the conductivity of different formulations of slurry and the settlement performance with the standing time. Assist R&D in slurry formulation development and mixing process stability monitoring.

Characteristic

1. Applicable to the conductivity evaluation of lithium (sodium) slurry and conductive agent slurry, to assist in research and development.

2. Separate the voltage and current lines, eliminate the influence of inductanceon voltage measurement, and improve the accuracy of resistivity detection.

3. The disc electrode with a diameter of 10mm ensures a relatively large contactarea with the sample and reduces the test error.

4. Three pairs of electrodes test the slurry resistivity and identify the slurry sedimentation performance.

5. Monitoring the changes of resistivity ofthe slurry in real time at threepositions in the vertical direction over time.

Application

1. Lithium (sodium) battery positive and negative electrode slurries

2. Conductive agent slurries material evaluation

3. Formula evaluation

4. Sedimentation performance evaluation.

Product Description

Disperse the powder into the liguid., Add it dropwise to the glass slide. Locate the single particle under an optical microscope. Control the pressure head to press down at a constant speed. Collect the force and displacement curves during the particle compression process and calculate the mechanical properties of the single particle.

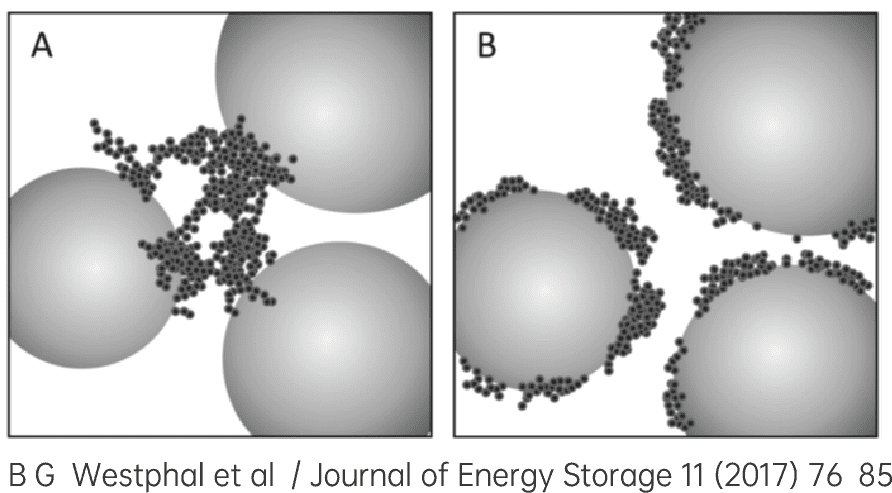

1. The Significance of Slurry Resistivity

The slurry is an important intermediate product in the production of lithium-ion batteries. The uniformity and stability of the slurry greatly affect the consistency and electrochemical performance of the final battery cell. The current method of monitoring slurry only has viscosity parameters, which cannot accurately evalu- ate the uniformity and stability of its electrical proper- ties. However, the slurry conductivity parameters and slurry formulation, conductive agent type and content, binder type andcontent etc, which all have significant correlation to monitor the production of slurry, and the slurry may have gel sedimentation after dwelling for a period of time after mixing. At this time, the conductivity value will also show varying degrees of change. Therefore, the conductivity of the slurry can be used as a method to characterize the uniformity and stability of the electrical properties of the slurry.

Monitoring the conductivity of the slurry, not only , it can evaluate the infuence of diferent active materials.conductive agents, binders, solid content, etc, on the electrochemical performance of the slurry, but alsoit can also be used for, monitoring the process stability, which can quickly identify abnormalities in the mixingprocess, and avoid the waste of time and cost caused by defective slurry flowing into the subsequent process.

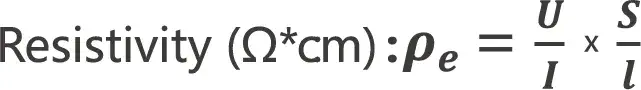

2. Battery Slurry Resistivity Test Principle

Test steps: Putting a certain volume of slurry (~80mL) into the measuring glass, inserting a clean electrode pen, start the software, start to test the changes in the slurry resistivity at the three pairs of electrodes over time and save it in the file.

Test parameters: Resistivity, Temperature, Time

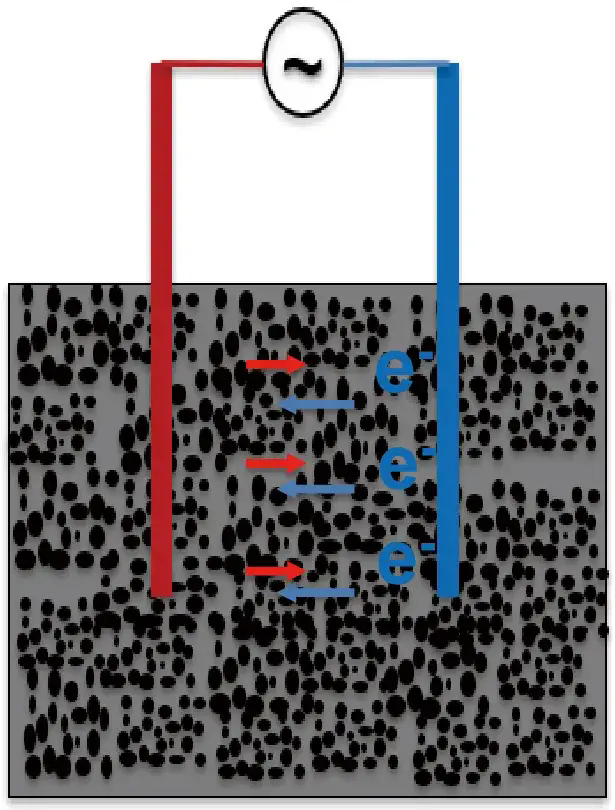

Calculation formula:

Features

1) Applicable to the conductivity evaluation of lithium (sodium) slurry and conductive agent slurry, to assist in research and development.

2) Separate the voltage and current lines, eliminate the influence of inductanceon voltage measurement, and improve the accuracy of resistivity detection.

3) The disc electrode with a diameter of 10mm ensures a relatively large contactarea with the sample and reduces the test error.

4) Three pairs of electrodes test the slurry resistivity and identify the slurry sedimentation performance.

5) Monitoring the changes of resistivity ofthe slurry in real time at threepositions in the vertical direction over time.

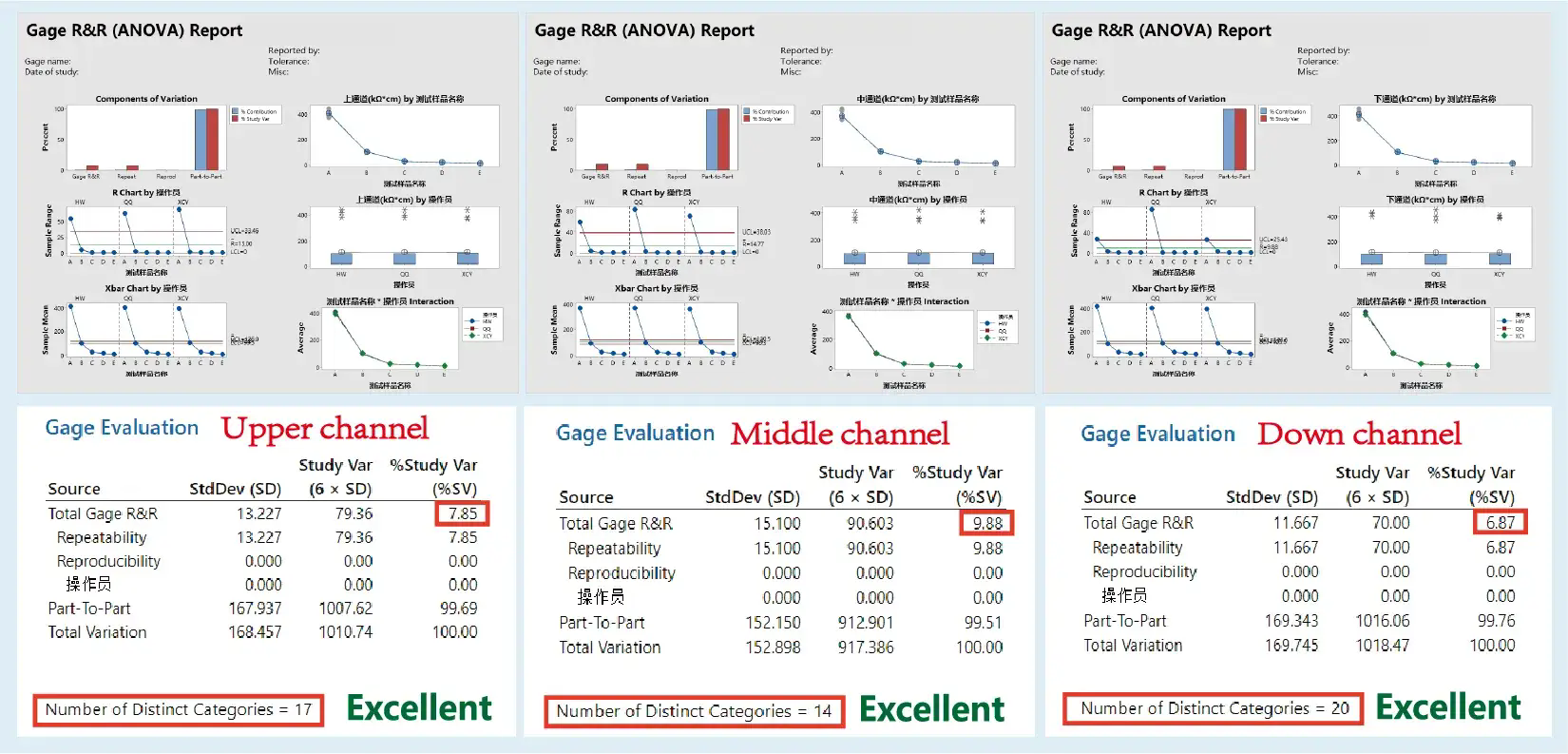

3. Slurry Resistivity Analyzer MSA

Test program: Three operators, five parallelsamples, and random testing

Test method: Sonicating the electrode pen withdeionized water for 30 seconds,and drying it with the dust-freepaper. Then five parallel sampleswas tested, and the fifth set of datawas taken for the GRR analysis

Application Cases

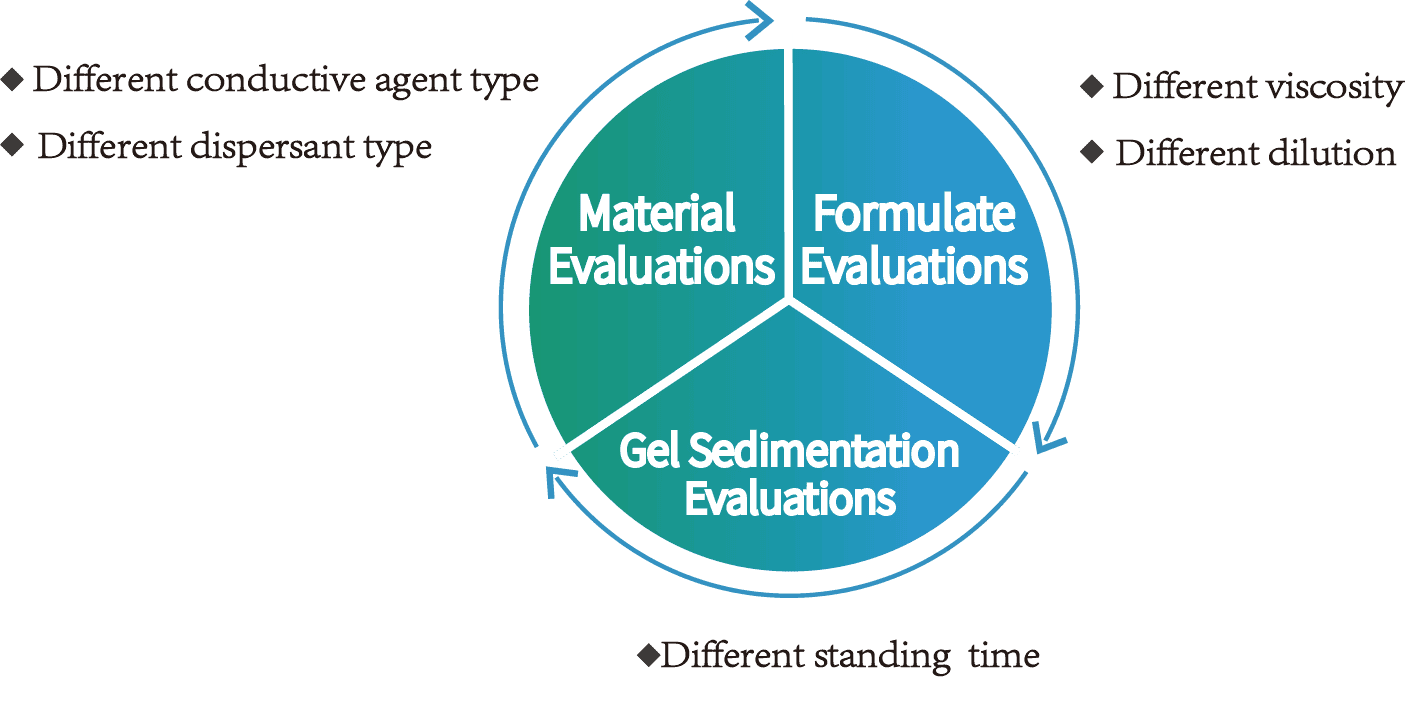

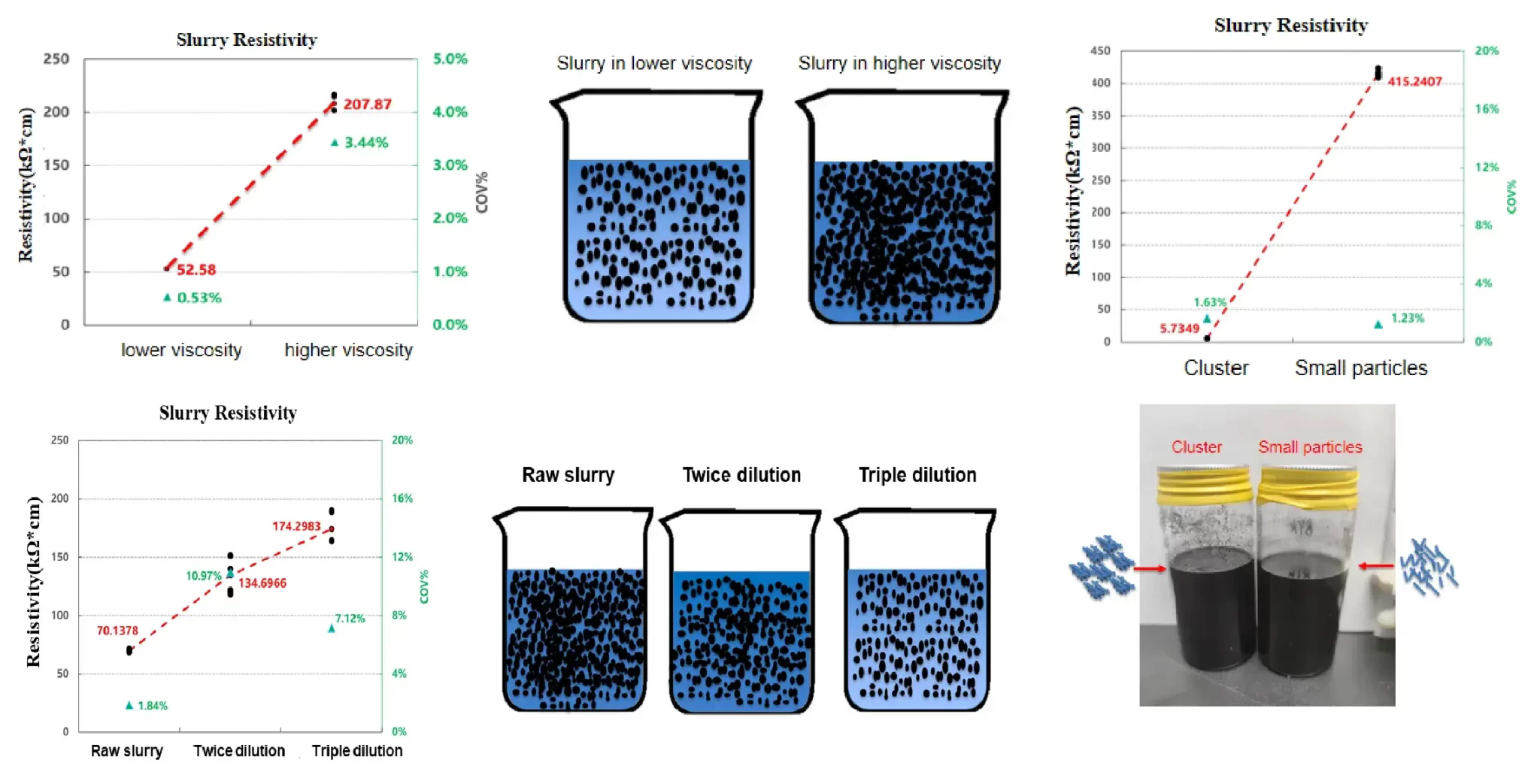

Case 1. Evaluation of Conductive Agent Slumy With Different Fommulations

1) When the viscosity, concentration and dispersant type of the conductive agent are changed, the resistivity also changes!

2) In the future, specifications can be forrmulated for the slurry resistivity of a certain fixed viscosity, and the stability of the slurry process can be monitored!

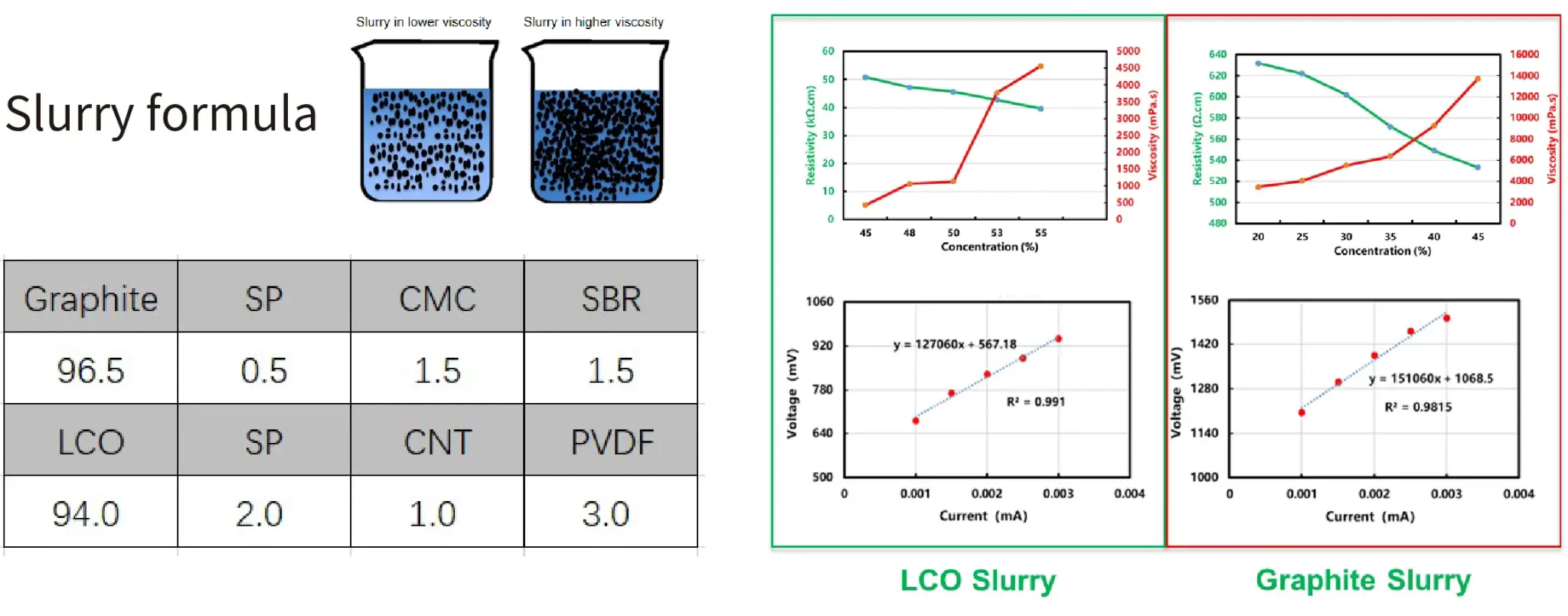

Case 2. Concentration-Viscosity-Resistivity Correlation

1) The resistivity of the slurry decreases with the increase of the concentration, and the change of the viscosity is also inversely proportional to the relationship;

2) The I-V curve test of these two types of slurries basically conforms to Ohm’s law, and the current and voltage have a linear relationship, indicating that the slurries are mainly electronic conductors;

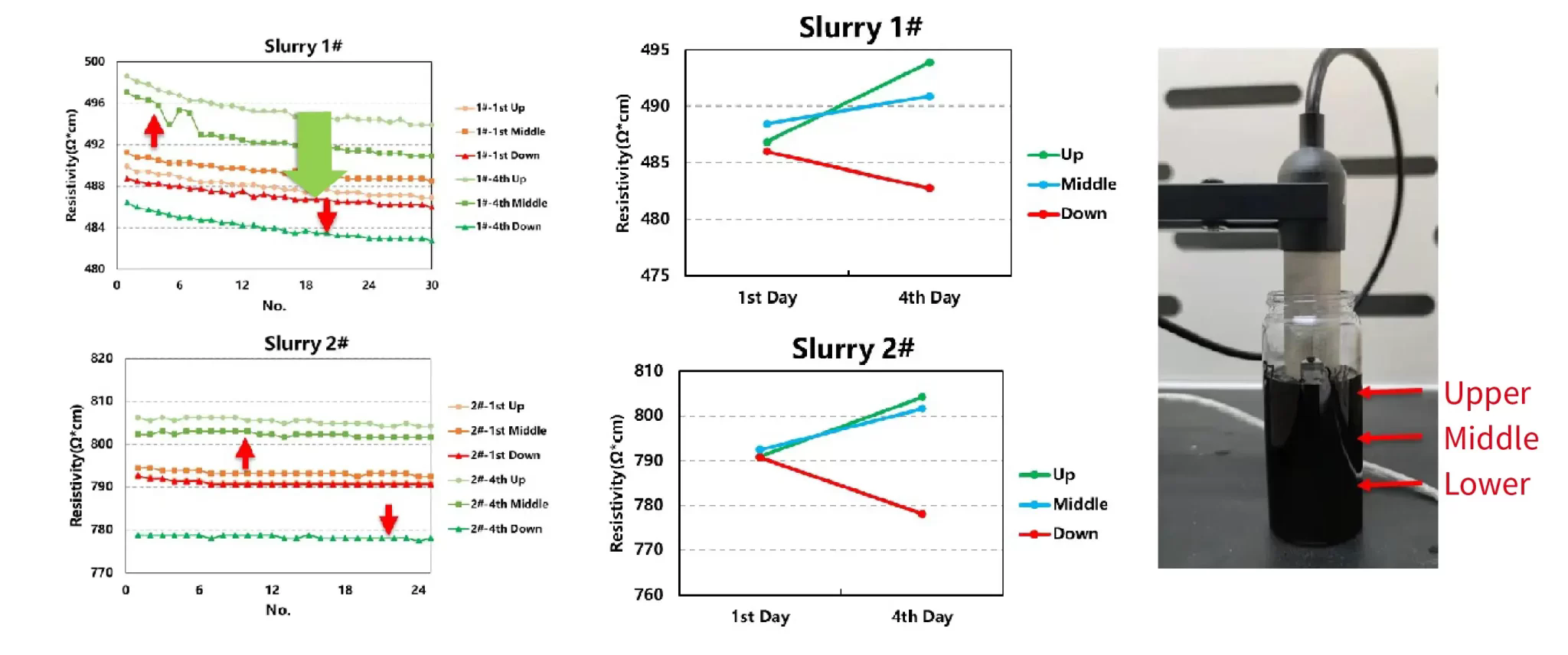

Case 3. Slurry Settling Performance

1) On the first and fourth day of testing, the resistivity of the upper and middle channels increased, while the resistivity of the lower channel decreased, indicating that after four days of shelving, the slurry shows obvious settlement.

2) Subsequently, a shelving period can be formulated for a certain of slurry according to the change of the resistivity to ensure the uniformity of the slurry!

Specifications

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com