products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

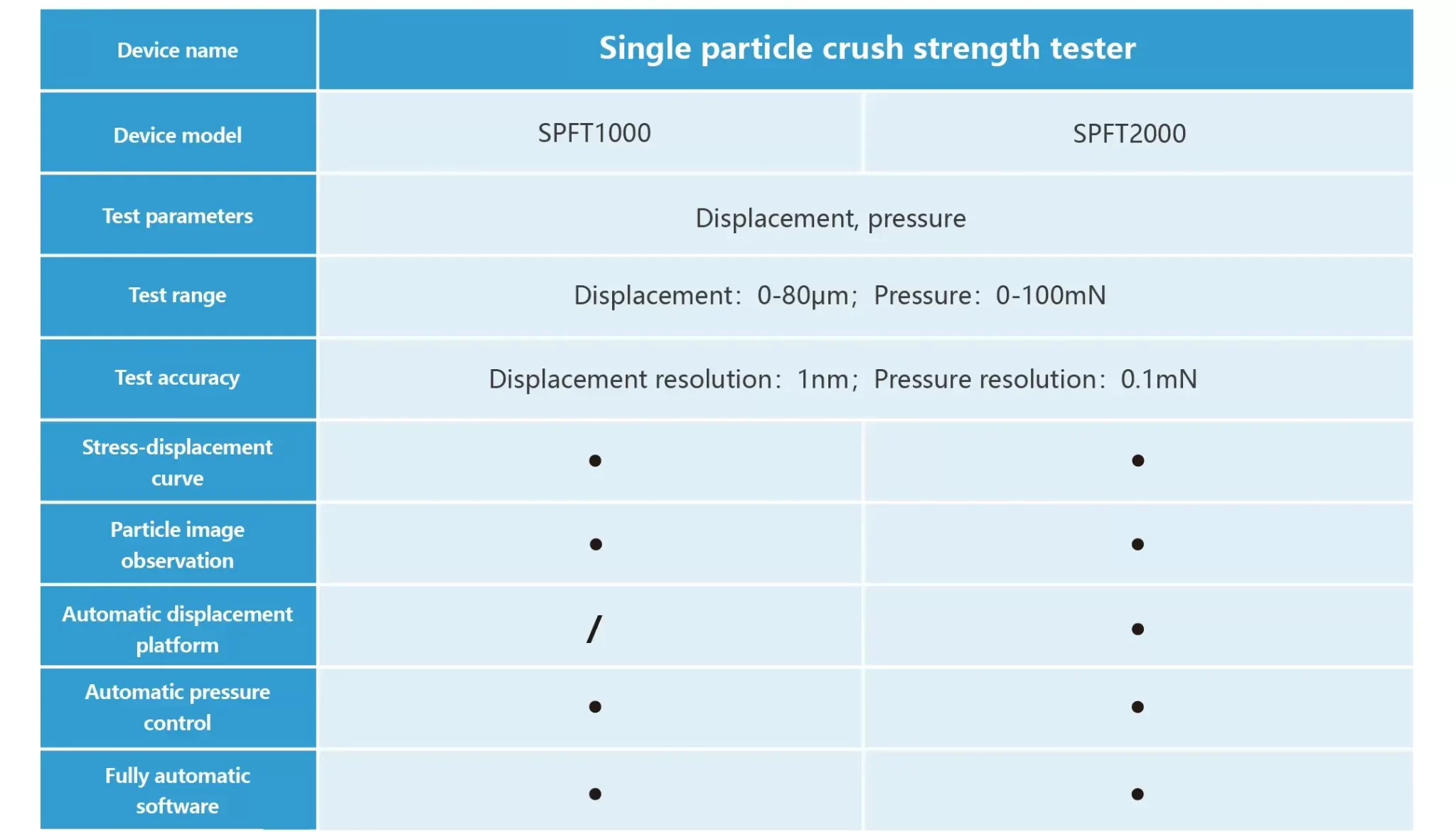

Single Particle Force Properties Test System

Model Number:

TMAX-SPFT2000Compliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Single Particle Force Properties Test System

Test Object

Lithium battery anode and cathode electrode materials

Test Particle Size

Single particle size: 5~50μm

Application

1. Testing the crushing strength of battery material particles

2. Can be used to evaluate the pressure resistance of the material

3. Guide the rolling process

4. Materials with high mechanical strength will have better subsequent cycle stability.

Product Introduction

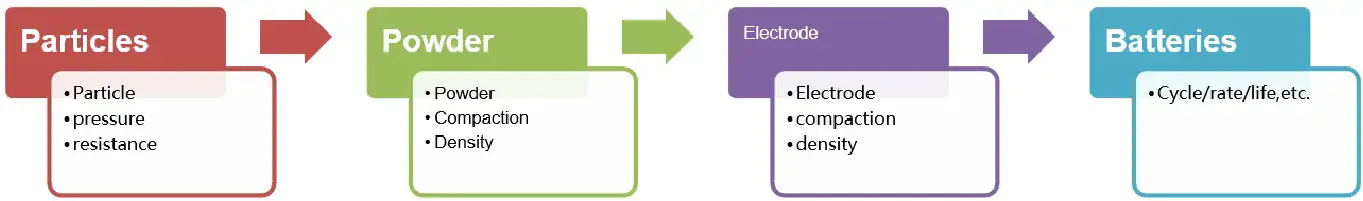

1.Background

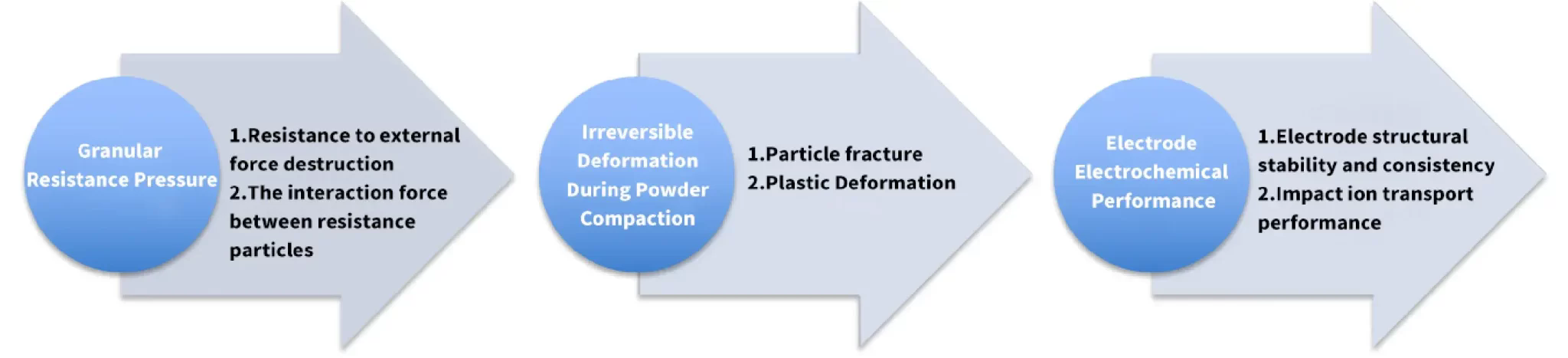

Testing the crushing strength of battery material particles can be used to evaluate the pressure resistance of the material and guide the rolling process. Materials with high mechanical strength will have better subsequent cycle stability.

2. Testing Object

Lithium battery positive and negative electrode materials(Positive: polycrystalline ternary; lithium-rich material; Negative: silicon-based, hard carbon, etc.; solid electrolyte)

3. Test Particle Size

Single particle size: 5~50 um

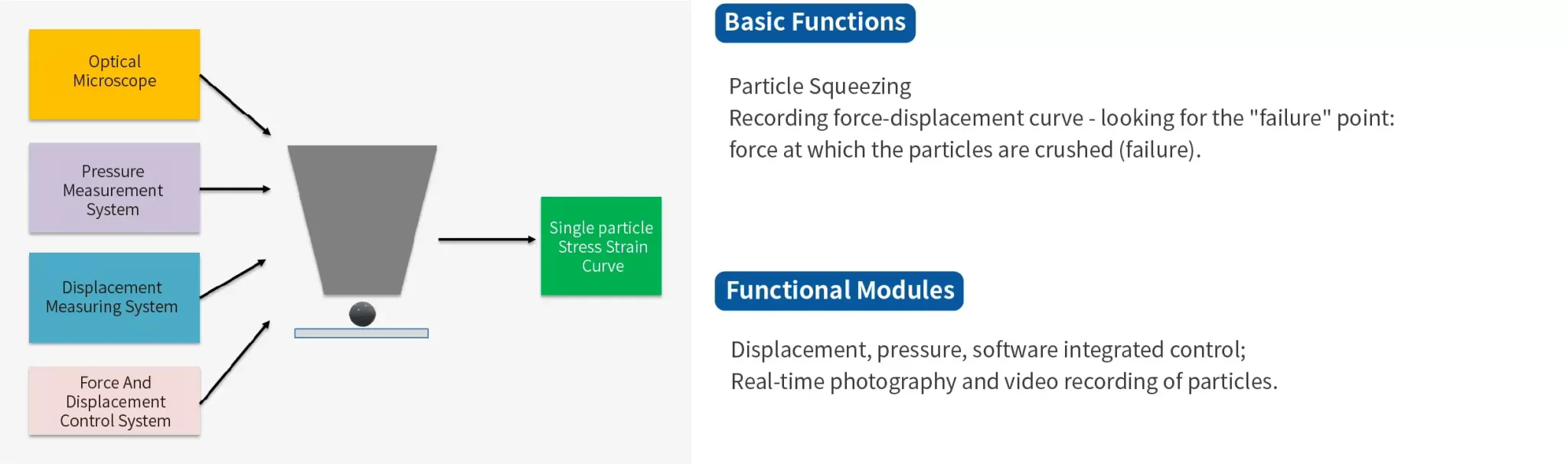

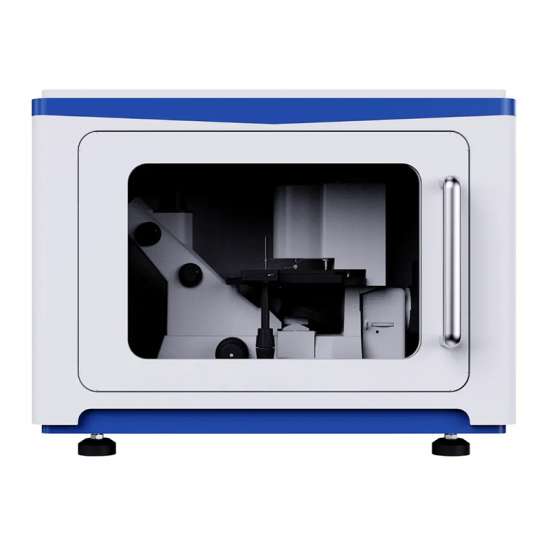

4. Equipment Composition

Testing Program

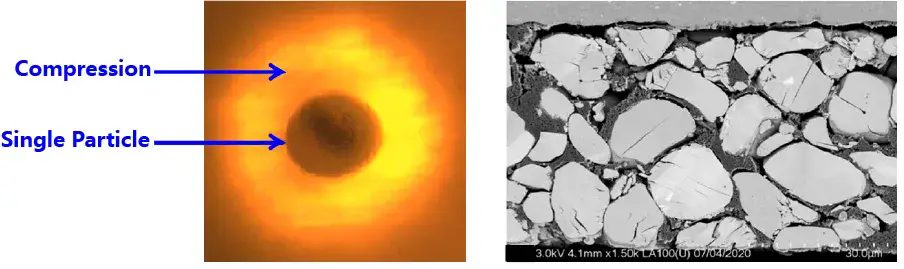

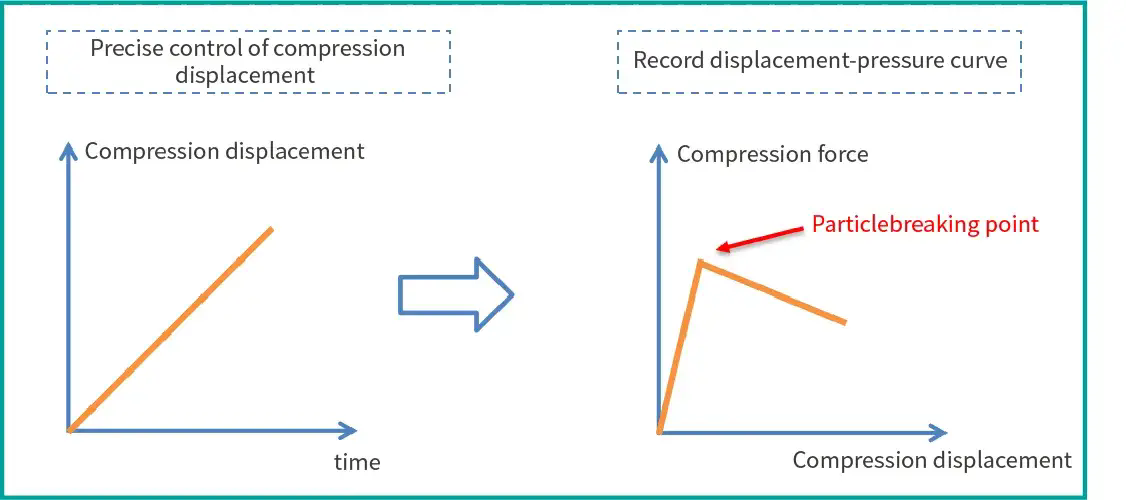

1. Testing Method

Disperse the powder into the liguid., Add it dropwise to the glass slide. Locate the single particle under an optical microscope. Control the pressure head to press down at a constant speed. Collect the force and displacement curves during the particle compression process and calculate the mechanical properties of the single particle.

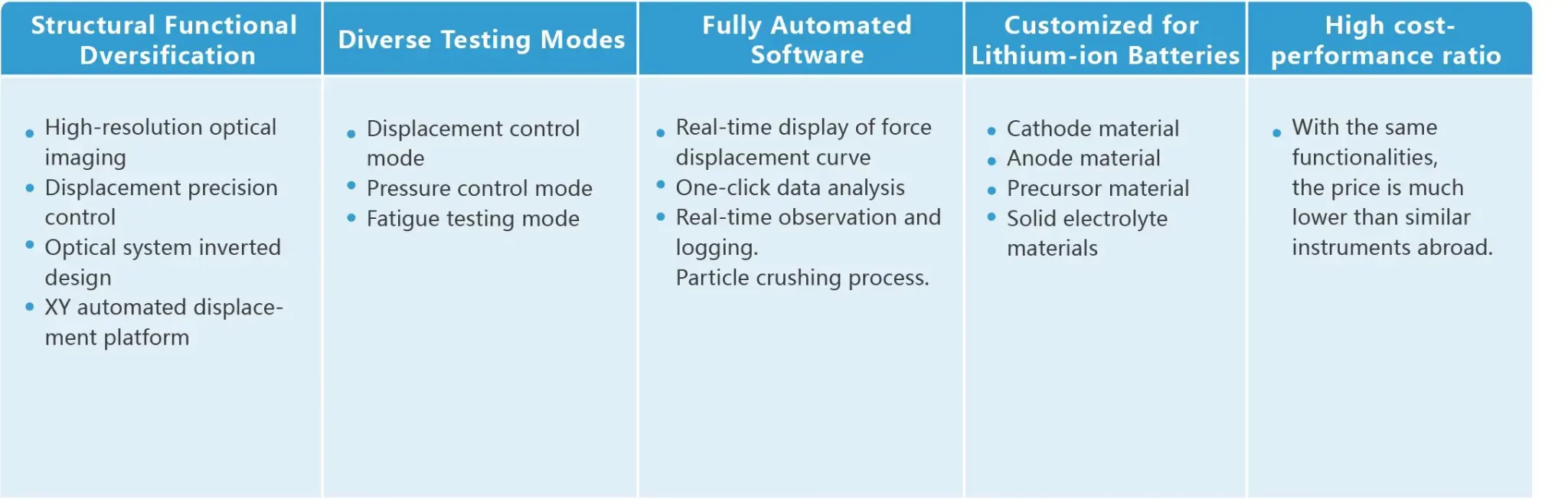

1) Magnification: up to 1200 times;

2) Pressure test range: 0-100 mN;

3) Pressure test accuracy: ±0.1 mN;

4) Minimum displacement unit: 10 nm;

5) Data collection frequency: 1000HZ.

6) Comply with national standard GB/T 43091-2023″Powder Compressive strength Test Method”

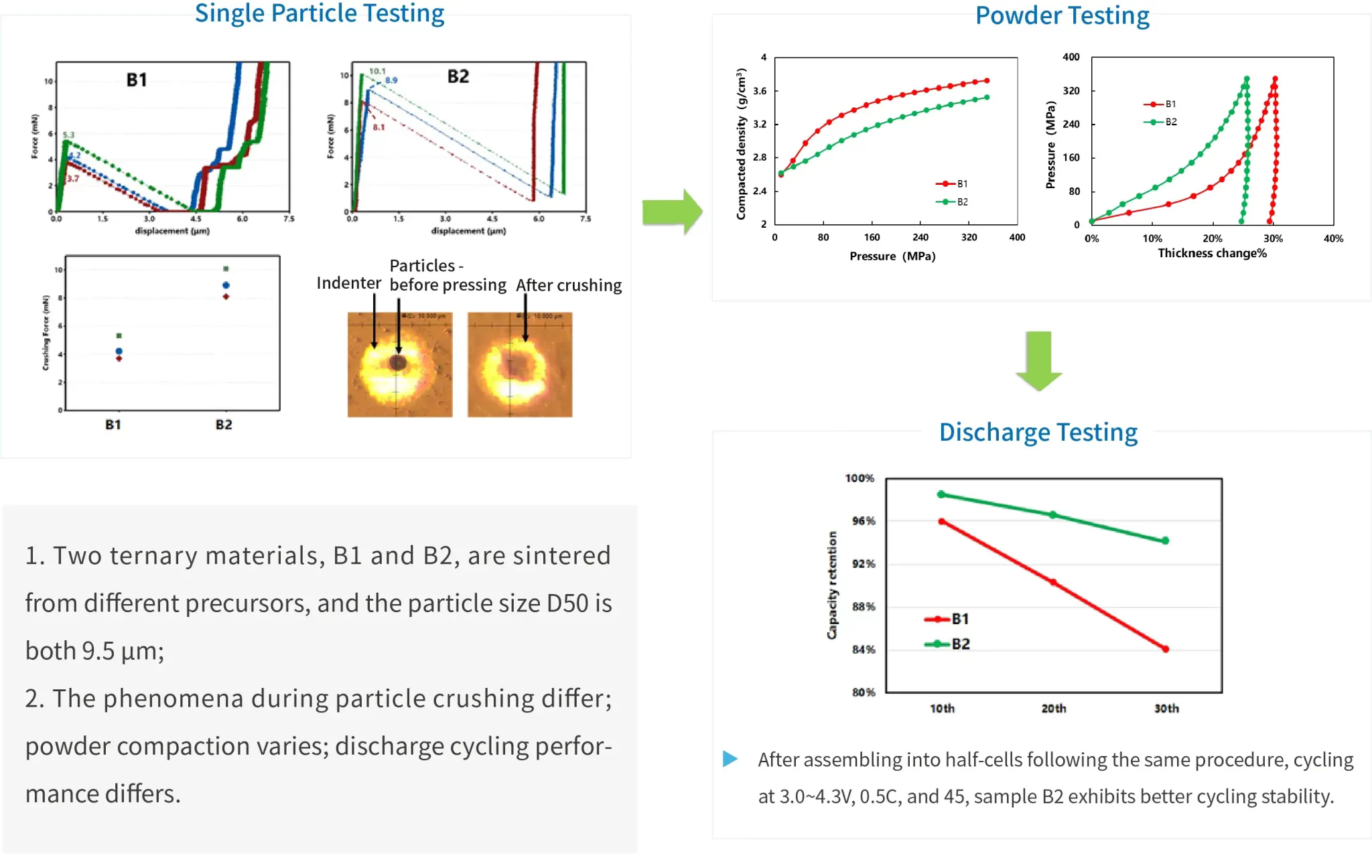

Application Cases

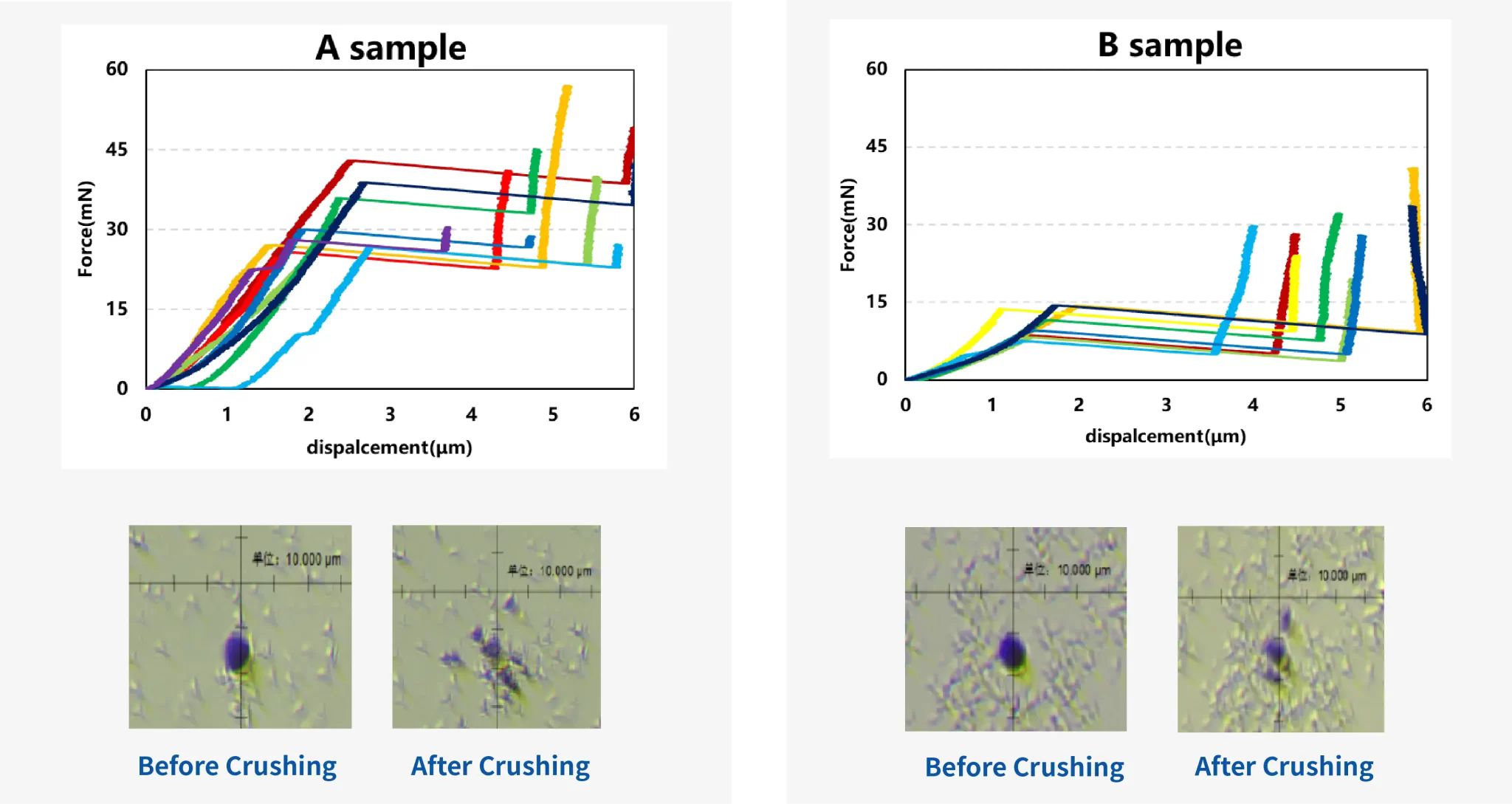

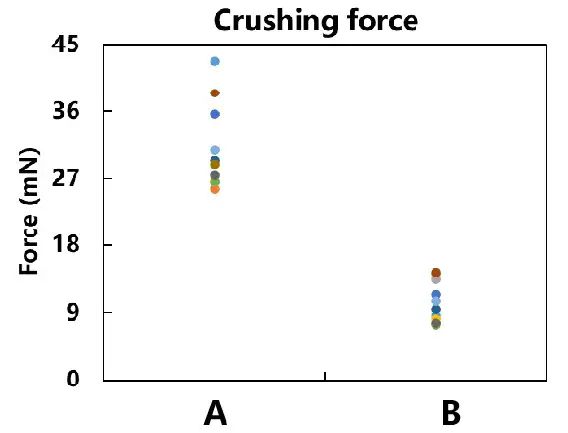

1. Anode Material-Sic

1) Two silicon-carbon materials with different electrode compaction.

2) Comparison of crushing force distribution: A>B.

3) Analysis of stress-displacement curves: Sample A exhibits initialmicro-crackingfollowed by complete collapse, while sample B expe-riences direct structural collapse and fragmentation.

4) Comparison of Disintegration States: after fracturing, all three groups disintegrate into fine granular states.

Particle Compression Resistance and Powder Compaction

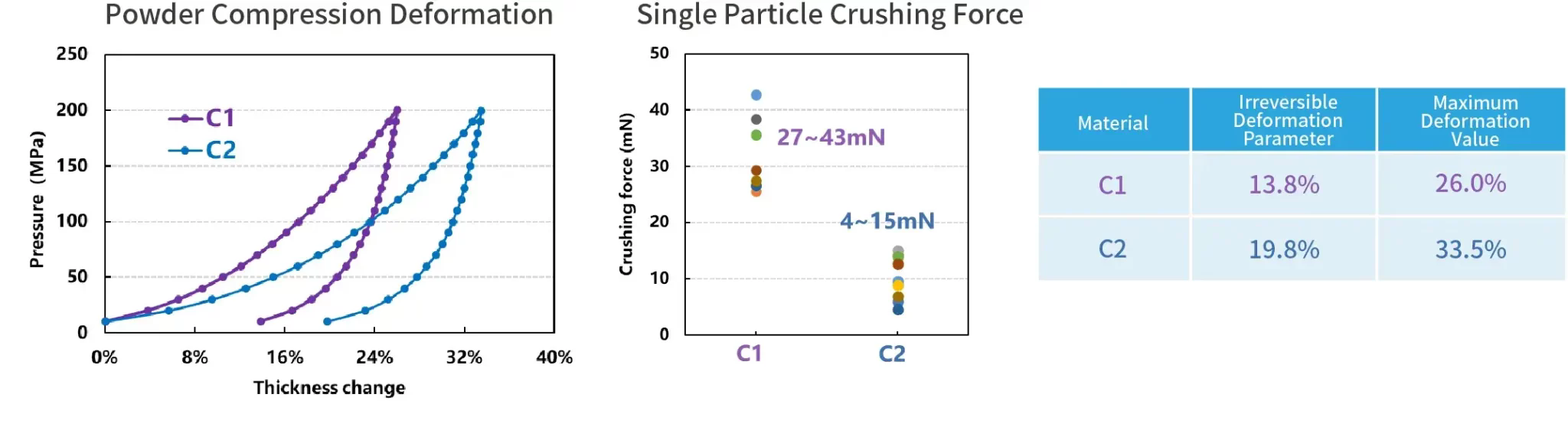

Case 1: Two Different Pure Carbons

The compressive resistance of particle level C1 is stronger. Corresponding to the powder end, C1has a higher compression modulus than C2, with both maximum deformation and irreversible deformation smaller than C2.

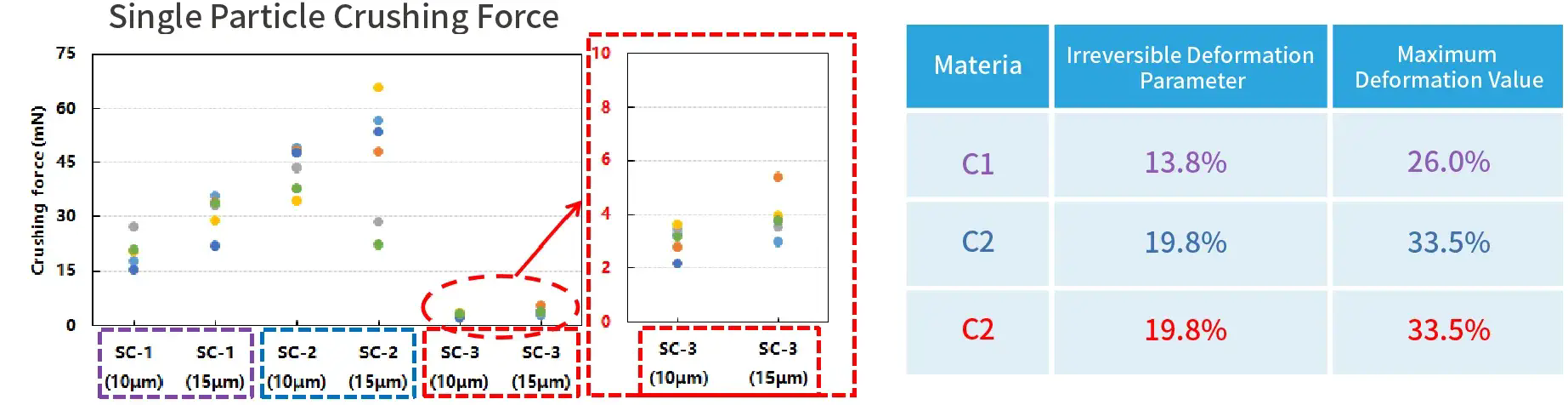

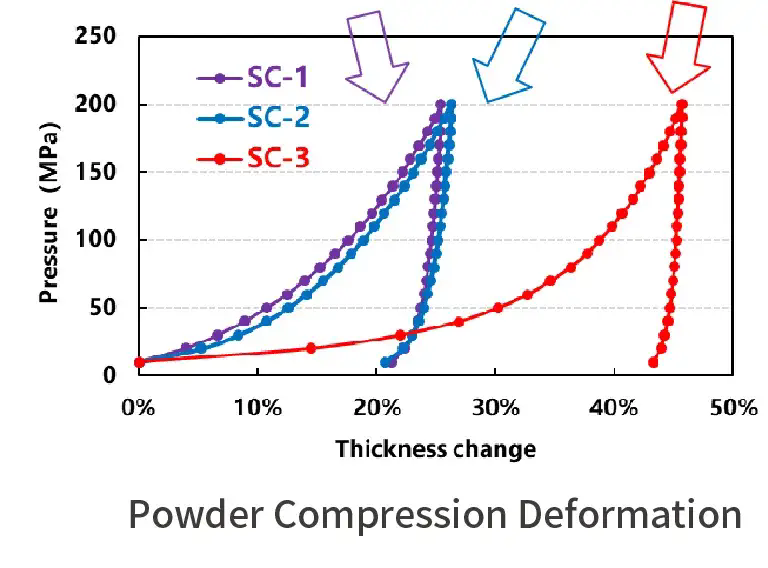

Case 2: Three Different Carbon-Silicon Materials

SC-3 has weaker compressive strength of its particles, resulting in significantly larger maximum deformation and irreversible deformation when the powder is compressed compared to theother two materials.

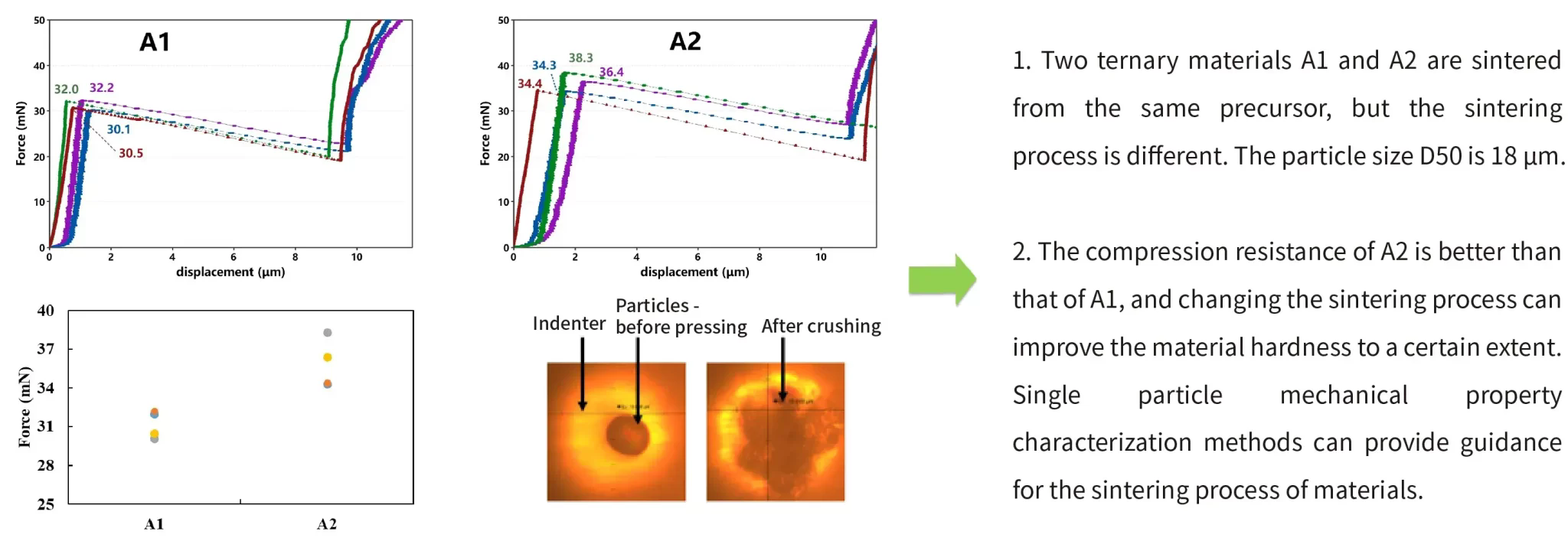

2. Ternary Cathode Material-NCM811

Specifications

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com