products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

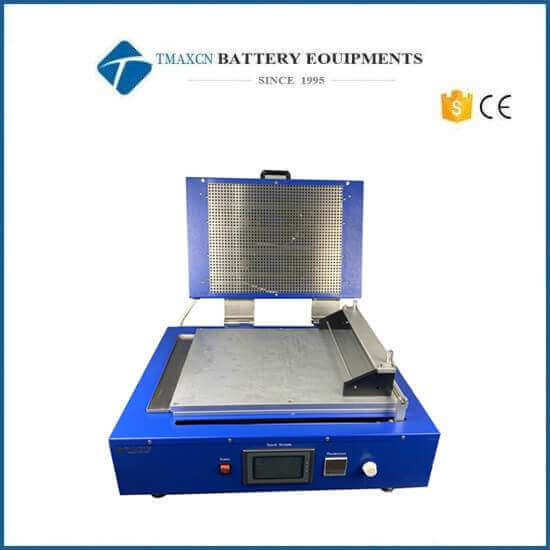

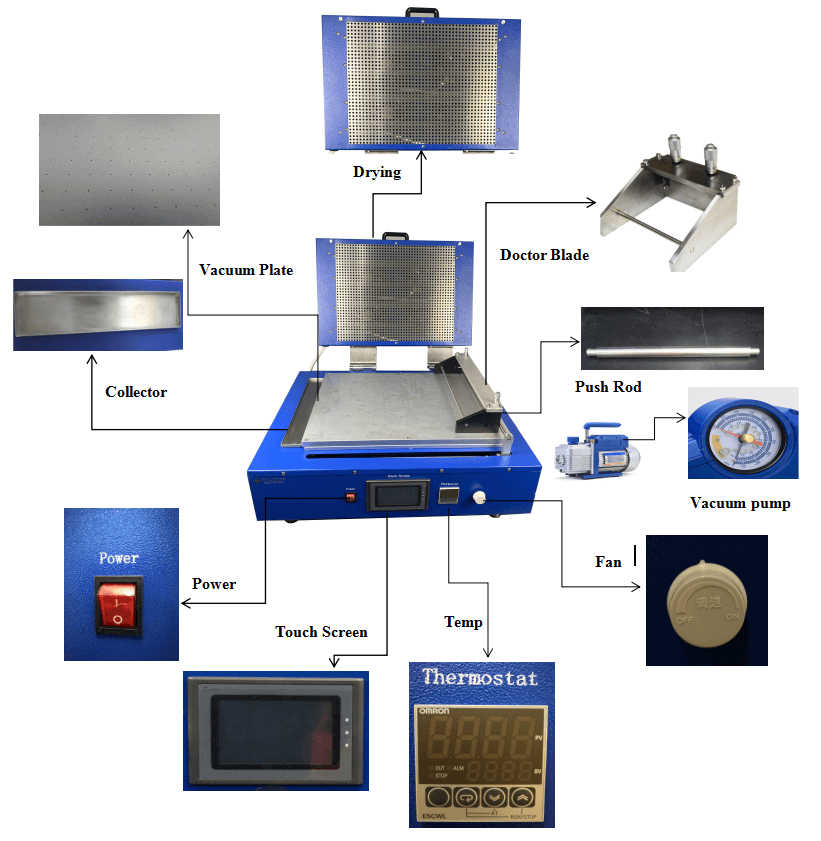

Heat Electrode Film Coater with Dryer Cover and 100-250mm Doctor Blade

Model Number:

TMAX-JK-TMJ-200Dimension(L*W*H):

100-250 mm widthNet Weight:

45-90kgCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Digital Pipette for Coin Cell Electrolyte FillingNext:

Lab Coin Cell Materials for Battery Research and Production

Heat Electrode Film Coater with Dryer Cover and 100-250mm Doctor Blade

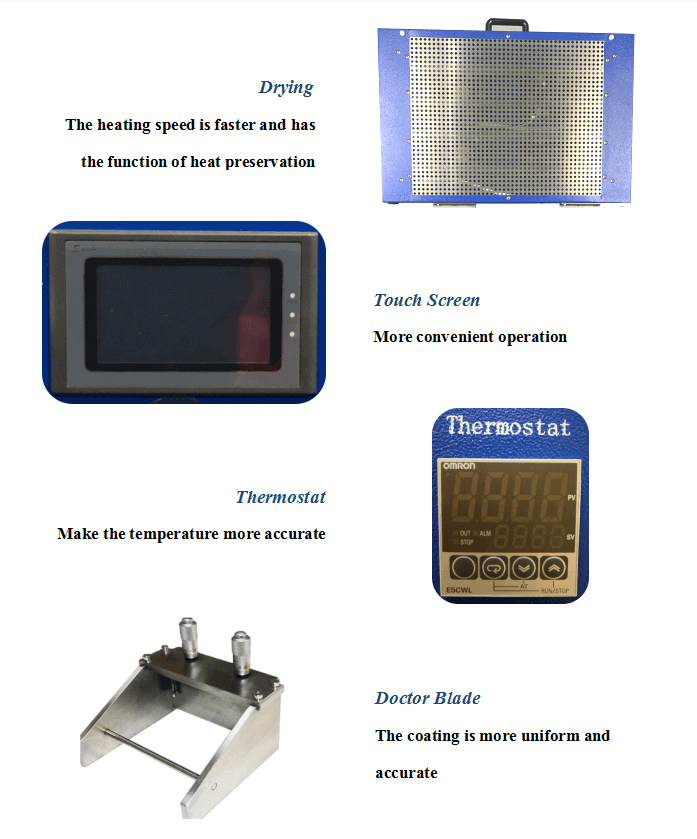

TMAX-JK-TMJ-200 is a compact tape casting coater with a heating cover designed to produce films with consistent

thickness. It has an unique driving system to produce smooth coating on all

types of materials. The flat vacuum chuck is built in to hold

substrate sheet in place, which is particularly useful when making thin

coatings. One 100 mm width adjustable micrometer applicator (doctor-blade) and

an oilless vacuum pump are included for immediate use. Heating cover with

digital temperature controller can dry films after coating up to 200°C with a

temperature accuracy of +/-1°C. This equipment can be used for

researches on ceramic tape castings and Li-Ion battery electrode coating. we are dedicated to providing quality blade coater for you.

| Main technical parameters |

Automatic coating dry machine |

| Source voltage |

AC 220V/110V, 50HZ |

| Power |

650W |

| Coating speed |

0-120mm/s, Step-less transmission |

| Max coating size |

100*250mm(could reach 250*300mm for similar type) |

| Vacuum board material |

Aluminum alloy |

| Vacuum board size(L*W*H) |

365*200*30mm |

| Slicker adjustable range |

0-6mm |

| Slicker width |

0-100mm(max. Reach to 250mm) |

| Heating dry system |

RT-200°C, Digital temperature controller |

| Temperature control accuracy |

±1°C |

| Dimension(L*W*H) |

550*330*320mm |

| Weight |

About 60kg |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com