products categories

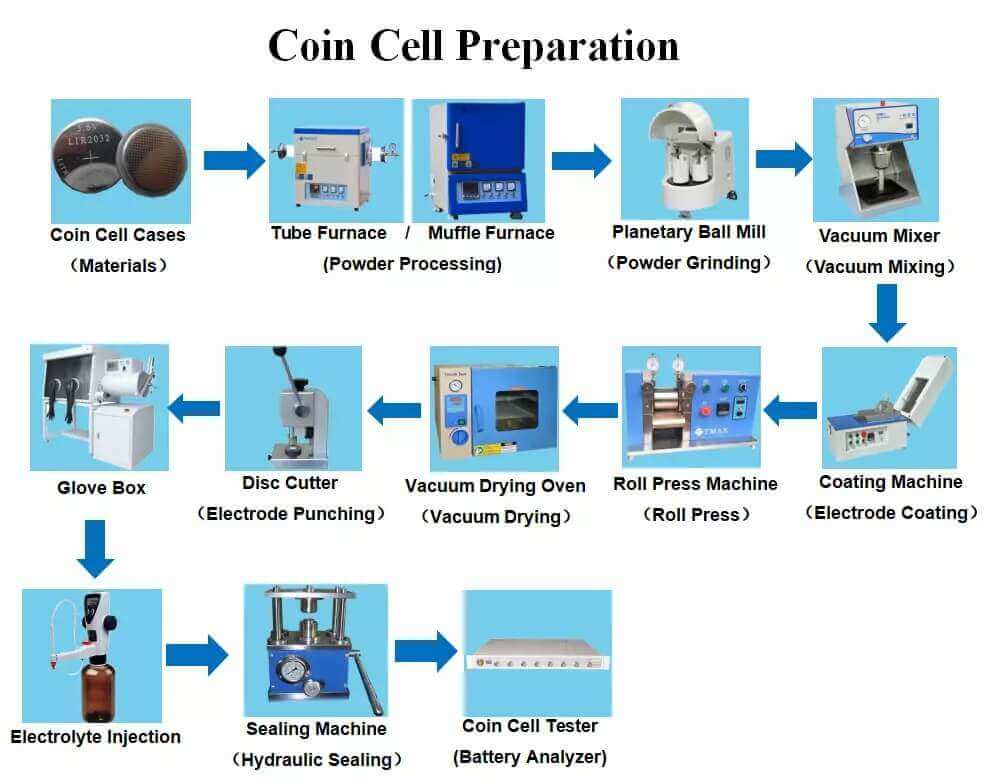

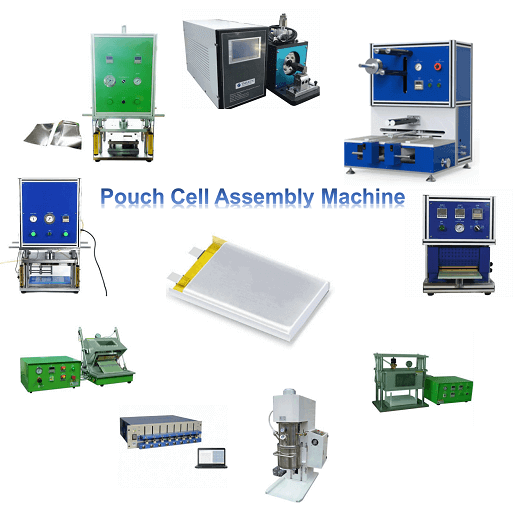

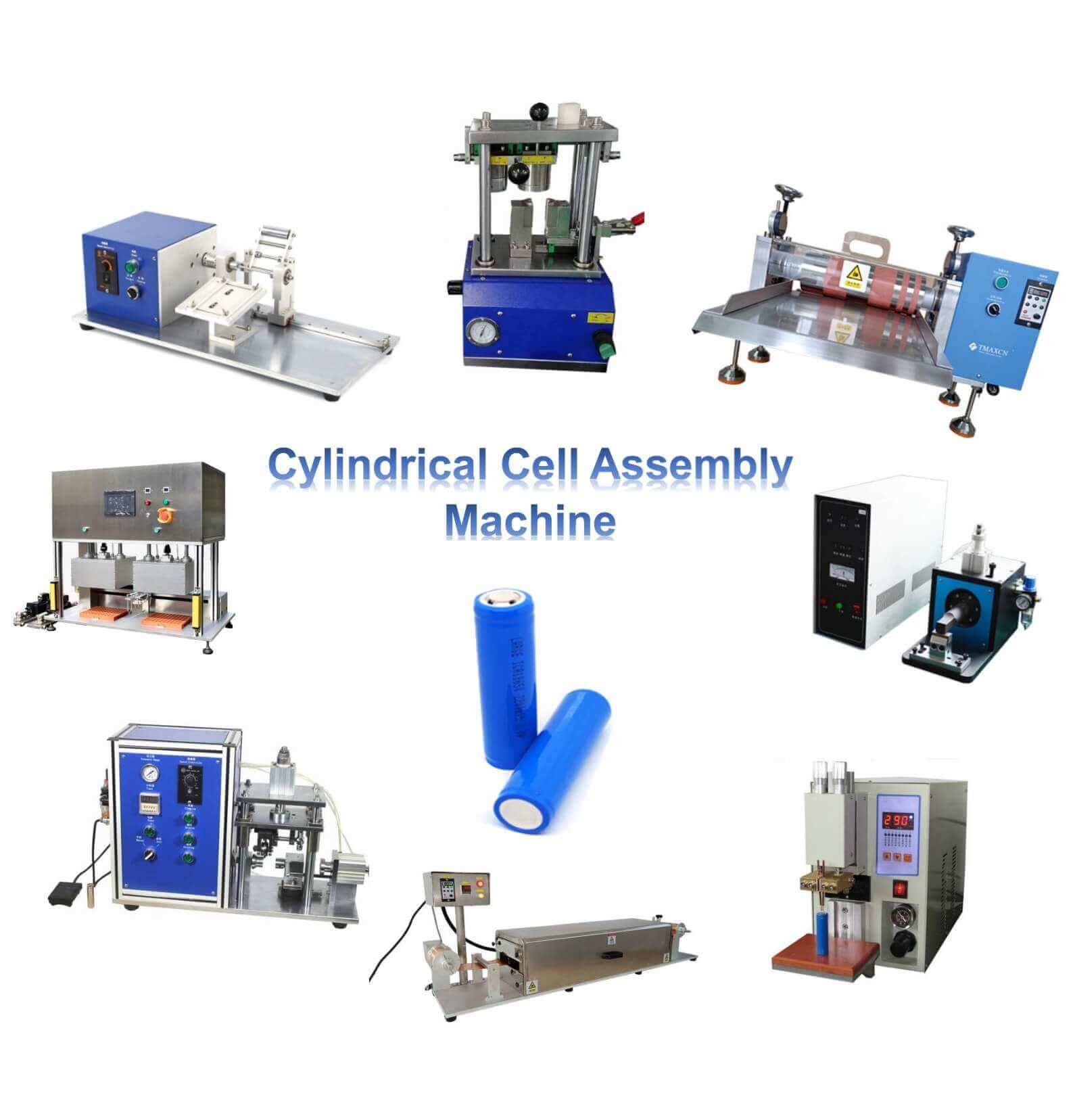

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Hydraulic Pressure Controlled Electric Roller Press Machine with Programmable Controller

Model Number:

TMAX-DG300Type:

Roller Press MachineDimension(L*W*H):

100mm-400mm WidthNet Weight:

60-120kgCompliance:

CE CertifiedWarranty:

One-year warranty and lifetime maintenanceDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Rewinding and Unwinding System for Battery Rolling Press MachineNext:

Three-Roll Electric Heated Horizontal Rolling Machine

Hydraulic Pressure Controlled Electric Roller Press Machine with Programmable Controller

Application

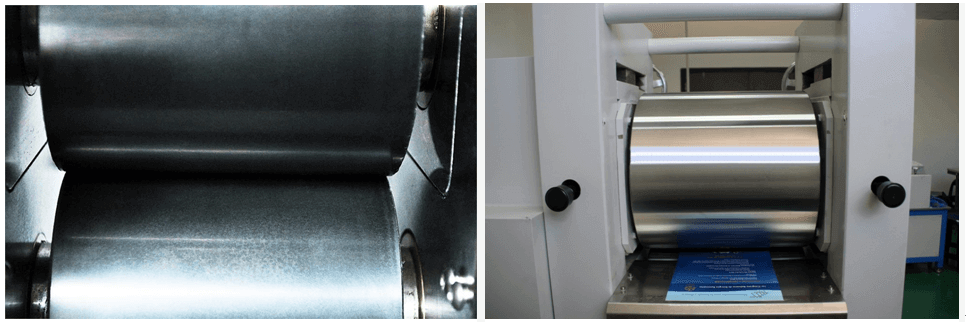

The hydraulic balanced rolling machine is designed for laboratory-scale battery material rolling with adjustable thickness and user-friendly operation. It is especially suitable for thinning and increasing the density of lithium battery electrodes, making it an ideal solution for clean energy applications.

Key Features

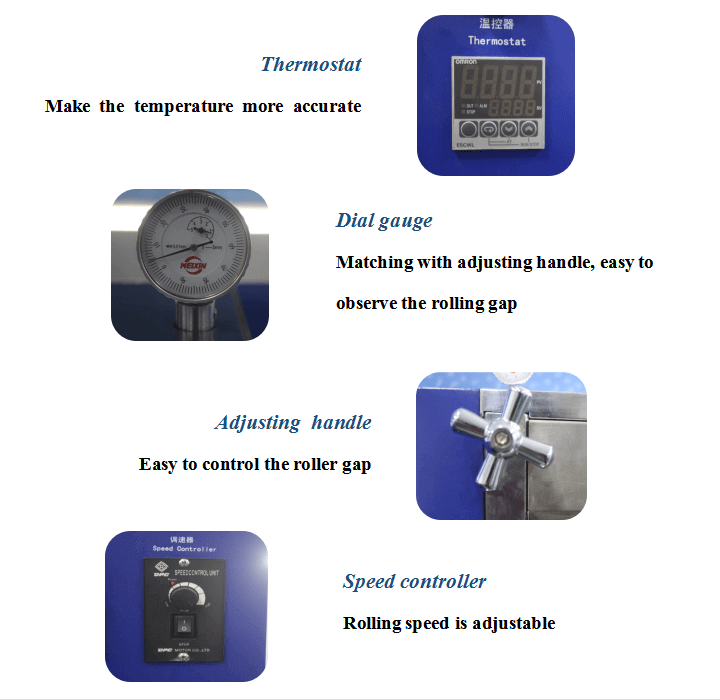

· Imported hydraulic system with automatic rolling pressure control.

· High-hardness rollers made from imported cold-rolled chromium-molybdenum (9Cr3Mo) material, with chrome-plated surfaces for superior wear resistance.

· Patented hydraulic balance rolling mechanism, ensuring stable pressure retention and uniform rolling in both horizontal and vertical directions.

· Integrated gantry frame with CNC precision machining, guaranteeing high accuracy and stability.

· Optional unwinding and rewinding system for enhanced functionality.

Technical Specifications

Parameter |

Specification |

Rolling Force |

Max 25T |

Mechanical Speed |

Max 6m/min |

Work Roll Diameter |

Φ200mm |

Roller Material |

9Cr3Mo |

Roller Width |

300mm |

Pressing Type |

Hydraulic |

Rolling Accuracy |

±2.5μm |

Roller Surface Hardness |

HRC62-68 |

Surface Roughness |

Ra 0.4 |

Rolling Drive |

AC variable frequency motor |

Installation Dimensions |

L1500mm × W1300mm × H600mm |

Power Supply |

380V |

Power Consumption |

1.5KW |

Air Supply |

0.5-0.8MPa compressed air |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com