products categories

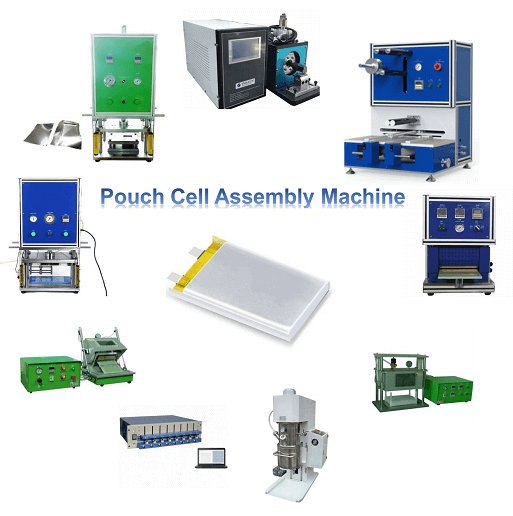

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Hydraulic Roll to Roll Pressure Controlled Roller Press Machine( 100 mm-300 mm Diameter) for Electrodes

Model Number:

TMAX-PXDimension(L*W*H):

200mm (Dia.) x 330mm(W)Net Weight:

500 kgCompliance:

CE CertifiedWarranty:

One-year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Roll to Roll System for Table Top Calender Machine up to 250 mm WidthNext:

Roll to Roll Pressure Controlled Roller Press Machine( 12" Width) for Electrodes - MSK-E2300B

Hydraulic Roll to Roll Pressure Controlled Roller Press Machine( 100 mm-300 mm Diameter) for Electrodes

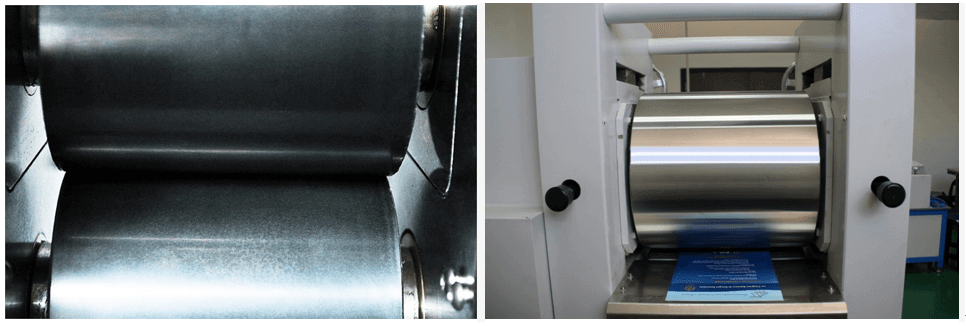

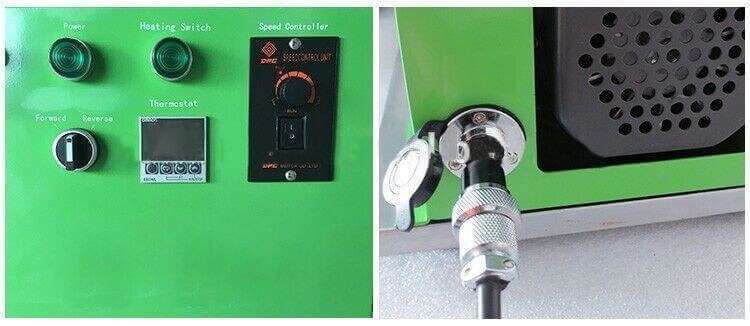

TMAX-PXis an Automatic Battery Electrode Rolling Press System with precision digital pressure control in a compact footprint that is less than 6'x6'. It integrates tension controlled feeding and winding devices together with Pressure Controlled Electric Rolling Machine to achieve attention-free electrode rolling & pressing up to 75 meters long with the 300mm max width. It is a perfect tool for building prototypes (e.g. pilot scale studies) of new generation rechargeable batteries to prepare electrode sheets at consistent and repeatable rolling conditions.

SPECIFICATIONS:

Working

Voltage |

|

Max. Power

Consumption |

1.5kW |

Rollers (one

pair) |

|

Press gap |

|

Motor & Rolling Speed |

|

Roller Surface Hardness |

|

Press

Planeness |

±0.0025mm |

Pressure Control |

|

Rectifying

Sensor |

Built in

Rectifying Sensor to ensure neatly reeling electrode foil after pressing |

Compressed air |

60psi

required (Air compressor is not included. |

Rolling Unit

Dimensions |

|

Warranty |

|

Net Weight |

1000 kg (2200 lbs) |

Shipping

Weight & Dimensions |

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com