products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

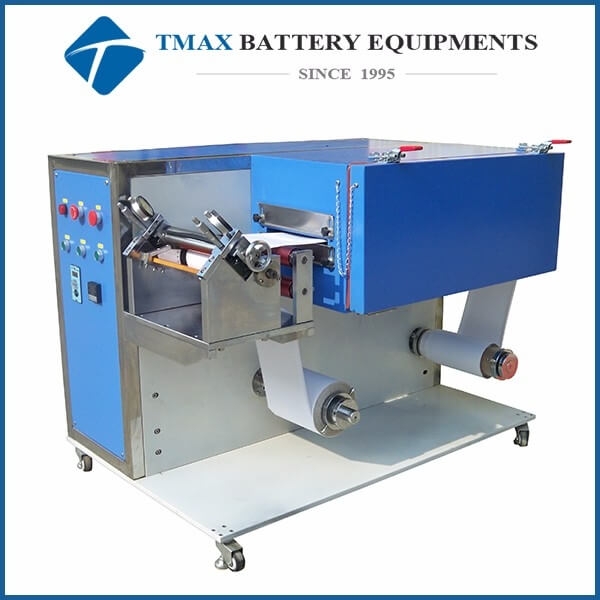

Lab automatic Battery Roll to Roll Electrode Coater Coating Machine

Model Number:

TMAX-SY300LDimension(L*W*H):

900*800*900mmNet Weight:

450kgCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Laboratory Electric Heat Film Coating Machine for Electrode Coater with DryerNext:

Battery Lab Vacuum Mixer with Vibration Stage & Two Al Containers (150 & 500ml) - MSK-SFM-7

Lab automatic Battery Electrode Coater

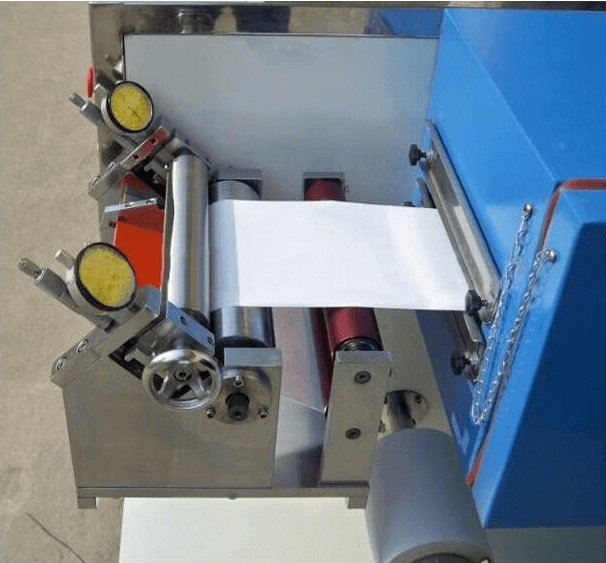

The continuous laboratory coating machine is a three-roller transfer-type coating system, designed for surface coating applications on various substrates. It is particularly suited for the lithium-ion battery industry, offering researchers a user-friendly solution while ensuring coating accuracy and consistency comparable to production standards. With excellent drying performance, it is an ideal choice for R&D and small-scale trials in lithium-ion batteries, supercapacitors, nickel batteries, and other secondary batteries.

Key Features

· Stable web tension control with an auto-correction system to ensure smooth substrate movement.

· Hot-air drying oven with dual-sided air blowing, providing superior drying performance.

· Three-roller transfer coating system, offering a wide coating window.

· Comma blade metering system with a precision adjustment mechanism for high coating accuracy.

· PLC control with touchscreen operation, making the system easy to use.

· Optional NMC solvent recovery and treatment system for enhanced environmental safety.

Technical Specifications

Parameter |

Specification |

Coating Method |

Three-roller transfer-type continuous coating |

Roller Width |

300mm |

Coating Width |

Max 280mm |

Mechanical Speed |

Max 900mm/min |

Oven length |

1 meter |

Coating Accuracy |

±3μm (Edge deviation: ±5μm) |

Coating Thickness |

40-200μm (Depending on slurry) |

Thickness Adjustment |

Manual adjustment |

Unwinding/Rewinding Diameter |

Φ250mm |

Rewinding Accuracy |

±0.5mm |

Tension Control |

Max 60N (Adjustable) |

Dial Indicator Accuracy |

1μm |

Drying Temperature |

Room temperature to 120°C (Adjustable) |

Drying Unit |

Standard hot-air drying system |

Compressed Air |

0.5-0.7Mpa |

Power Supply |

AC 220V / 50Hz |

Max Power |

5KW |

Machine Dimensions |

L1800 × W1200 × H1200mm |

Weight |

Approx. 1T |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016