products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

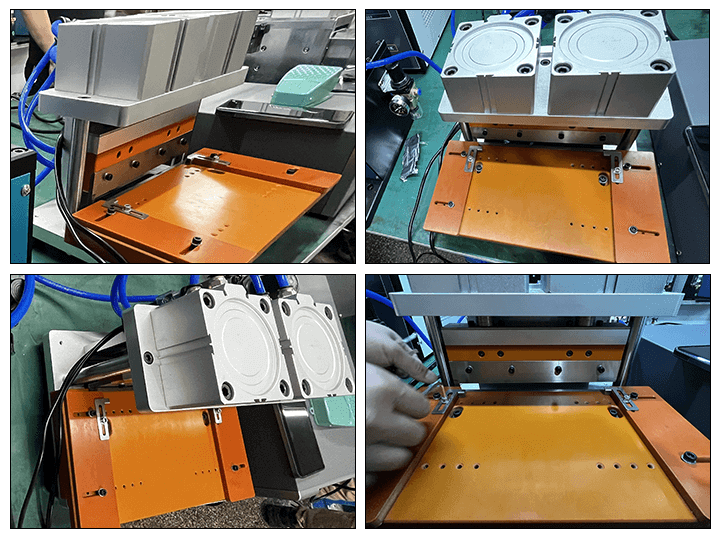

Lab Double Tabs Cutter and Shaping Machine for Lithium Battery Making

Model Number:

TMAX-QJH300Compliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Single Side Double Work Station Vacuum Glovebox with Purification SystemNext:

Pouch Cell 3 in 1 Vacuum Sealing Machine For Battery Making

Lab Double Tabs Cutter and Shaping Machine for Lithium Battery Making

Introduction

It is mainly suitable for the flat pressing and shaping after cutting the tabs of laminated cells, fixed-length cutting and trimming of the electrode tabs of the batteries, and the double cutters are mutually insulated.

Main features

*Shangyin linear slide rail group is used for guiding, and the guiding accuracy is extremely high to ensure zero clearance between the upper and lower cutters and long service life, the upper and lower die are flat;

*Simple operation, high efficiency, stable temperature and good consistency.

*Using fixtures to assist the feeding, the cylinder drives the mold to achieve shaping.

*Set a product positioning tray to facilitate the positioning and placement of batteries;

*Beautiful, reliable, convenient and fast;

*The speed of the upper and lower platens and the shaping time can be adjusted and set;

*The upper and lower cutters are made of high-speed steel, with sharp blades;

*Double cutters are insulated from each other;

*The cylinder controls the cutter to trim the battery pole piece and tab, which is easy to be automated;

*Set the product positioning tray to facilitate the positioning and placement of the batteries.

*Beautiful, reliable, convenient and fast;

Technical parameter

Mold hardness |

≥HRC58 |

Mold life |

3 million times / grinding |

Upper and lower pressure plate material |

Imported S136 material, no deformation, no rust |

Shaping temperature |

RT~250℃ |

The distance between the upper and lower pressing plates |

>50mm |

Single cutter |

80mm long |

Insulation |

The left and right cutters are insulated from each other |

Position |

The blade positioning block of the tab cutting machine and the battery side positioning block are adjustable |

Cutter life |

1 million times/grinding |

Speed |

Air pressure 600 times/hour |

Air compressed air source |

0.5Mpa~0.7Mpa |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com