products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

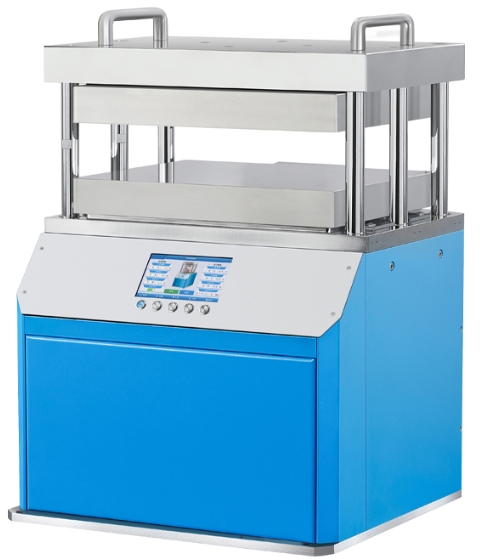

Laboratory Automatic 50T 300C Hot Pressing Machine with Multi-stage Programmable

Model Number:

TMAX-PP-600GCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Width 3 to 10mm Alloy Tool Steel Hydraulic Press Machine Ordinary Square MoldNext:

Lab 10T 1000C 20-segment Programmable Automatic High Temperature Heat Press Machine

Laboratory Automatic 50T 300C Hot Pressing Machine with Multi-stage Programmable

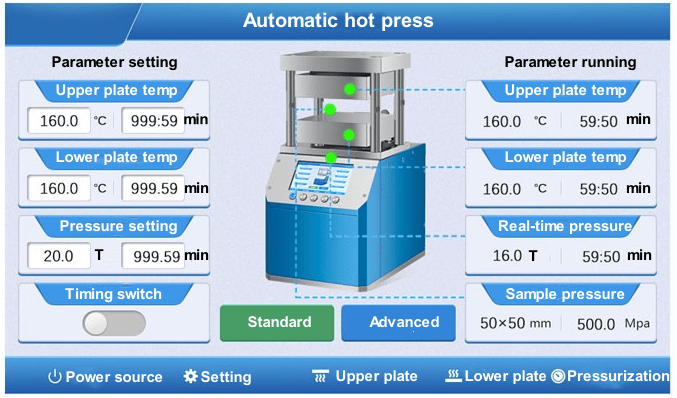

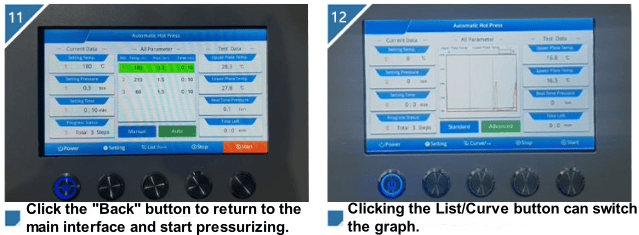

Operation interface (Standard mode)

Standard interface: The heating temperature and constant temperature time of the upper and lower plates can be set separately on the interface.

Pressurization button: Press according to the parameters set on the interface.

Upper plate button: Heat the upper heating plate.

Lower plate button: Heat the lower heating plate.

Timing switch: The timing function can be turned on and off.

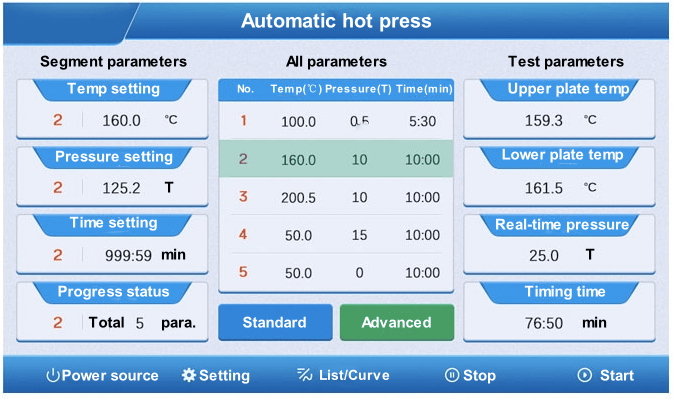

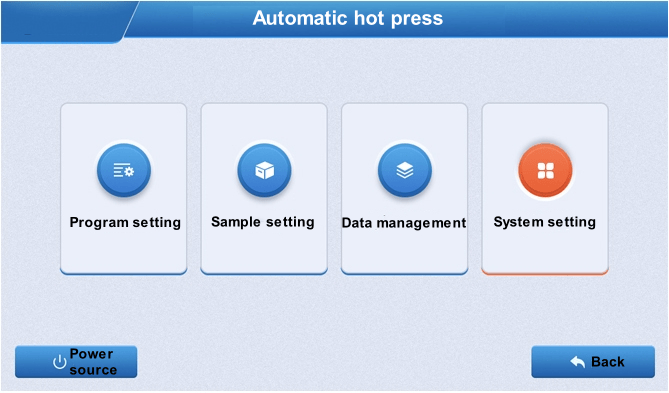

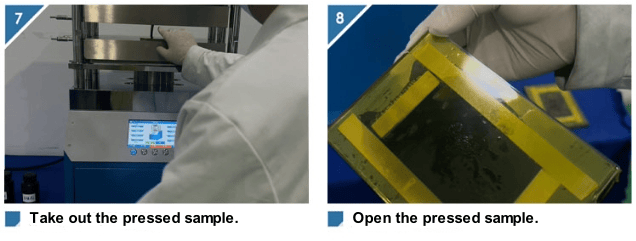

Operation interface (Advanced mode)

Start button: It can be pressurized according to the multi-stage pressurization program.

Stop button: During the heating process, pressing the stop button can stop the heating.

Settings button: Click the Settings button to enter the Settings menu.

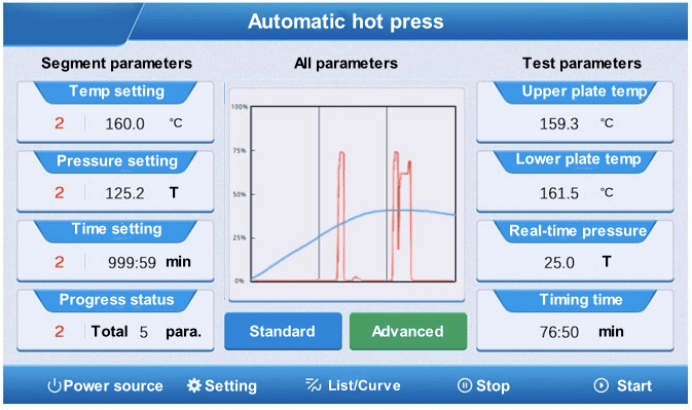

Operation interface (Advanced mode)

List/Curve: The current display state can be switched between list and curve.

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings:Multi-stage pressure procedures and pressure holding times can be set.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

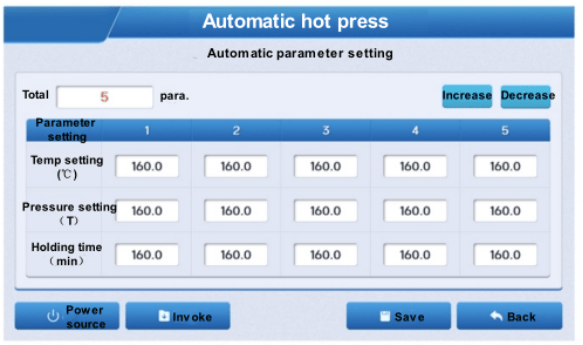

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Invoke the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

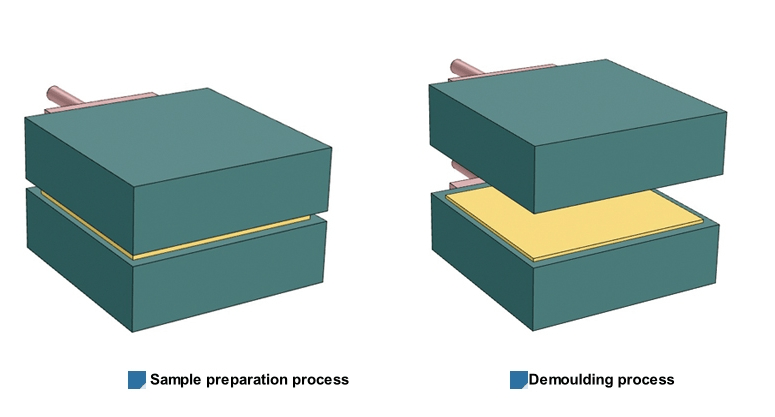

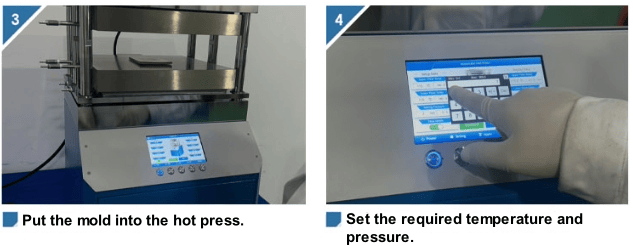

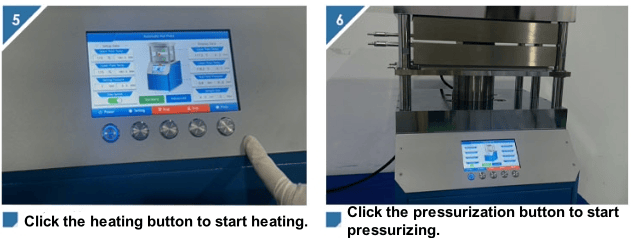

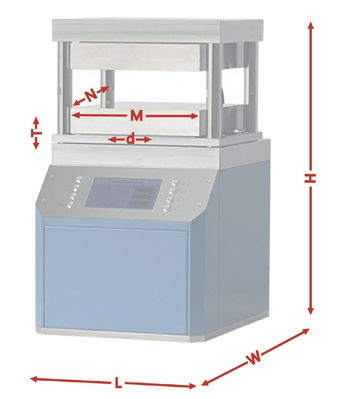

Mold operation diagram

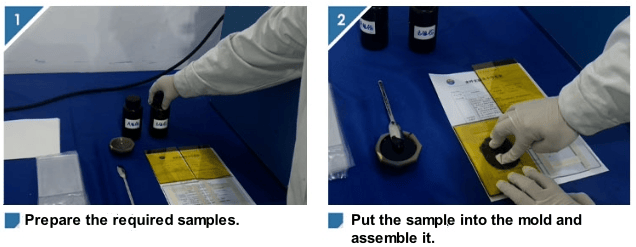

Operation procedure

Technical parameter

Instrument type |

PP-600G |

Pressure range |

0-50.0 tons |

Pressurization process |

Programmed pressure - programmed pressure retention - timed pressure relief |

Holding time |

1 s to ∞ s |

Mold heating temperature |

Room temperature -300.0℃ |

Constant temperature time |

1 s to ∞ s |

Temperature control accuracy |

0.1 ℃ |

Heat insulation method |

Imported heat shield |

Cooling method |

Water cooling rapid cooling [Optional water cooler] |

Mold size |

500x500mm(MXN) |

Overall size |

800x850x820mm(LxWXH) |

Power source |

5500W(220V/110V can be customized) |

Main engine weight |

880 Kg |

Hot press size diagram |

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com