products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Manual 18650 Lithium Battery Pack Assembly Line Project

Model Number:

TMAX-18650BPType:

Manual lineCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Single Side CNC Automatic Spot Welder with 5000A / 8000A Inverter DC Welding Power Supply / Transistor Welding Power SupplyNext:

Battery Pack Assembly Plant for 18650 Cylindrical Cell

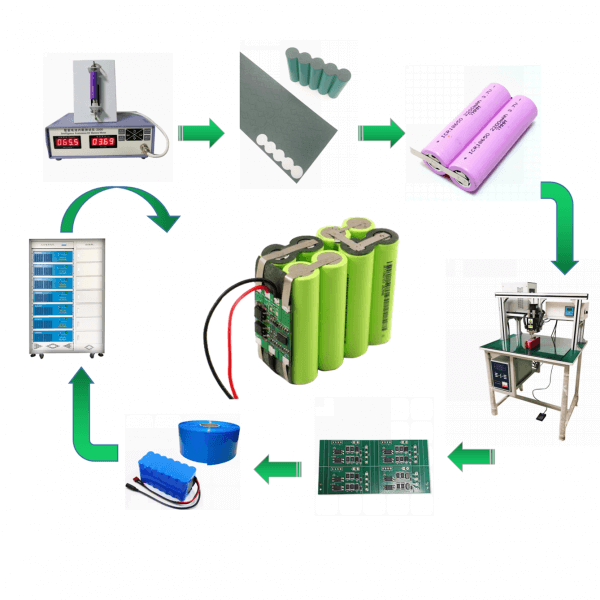

Manual 18650 Lithium Battery Pack Assembly Line Project

Features:

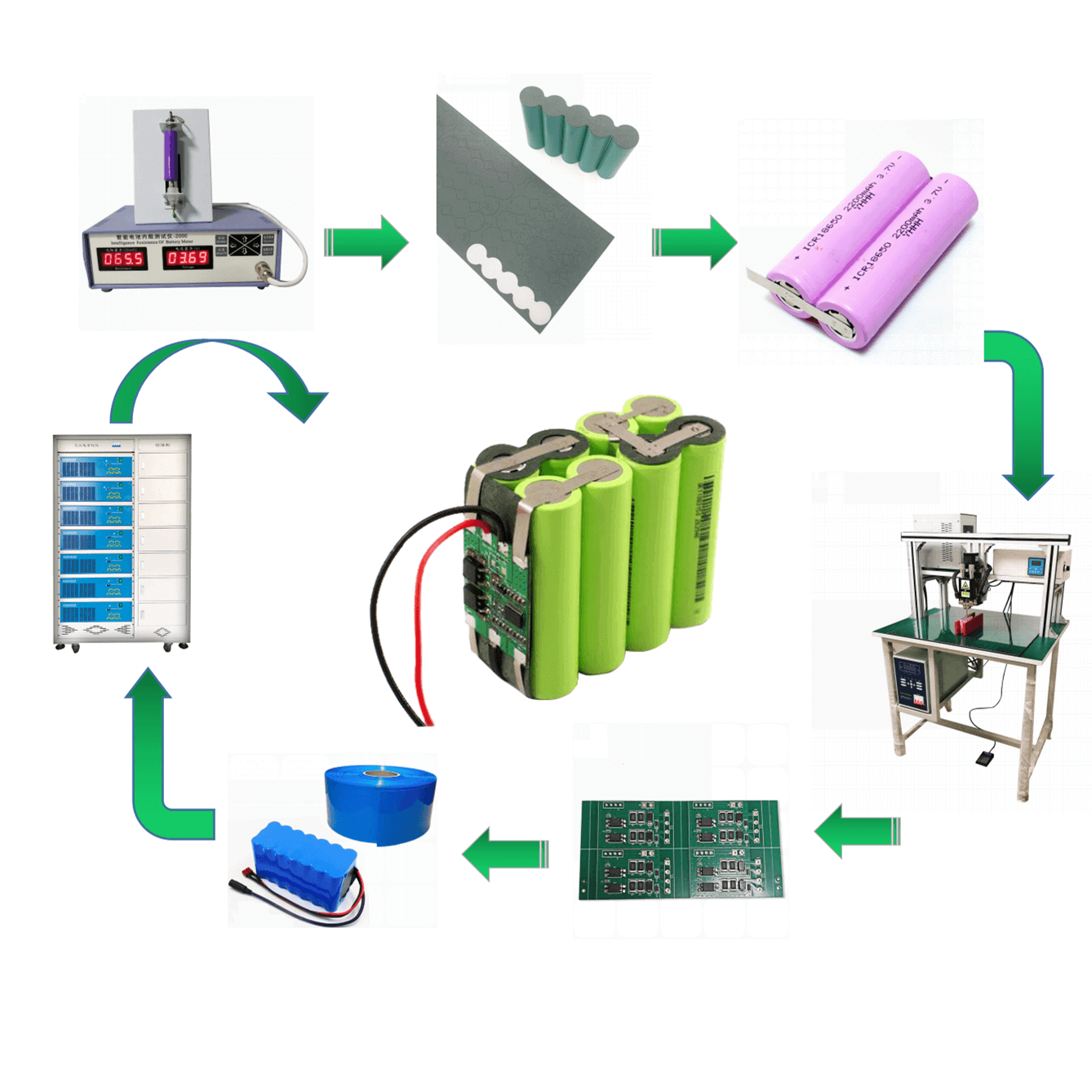

The general 18650 lithium battery pack includes: 18650 cell, battery protection board, connecting nickel strip, insulating paper, wire; PVC outer package or shell, output (including connector), key switch, power indicator, EVA, highland barley paper, plastic bracket and other auxiliary materials.We provide a full series of Energy Storage Battery Assembly for different customers.

18650 Lithium Battery Pack Process Quality Features:

1. The use of qualified lithium batteries requires qualified and stable suppliers to provide single batteries with good performance. After a series of safety tests and performance tests, the single batteries can be used after they are qualified.

2. No matter 14.8V lithium battery pack or other energy storage battery pack, it should ensure low internal resistance, high current discharge capacity, platform and heat dissipation.

3. The structure of the battery adopts ventilation design, and the space between the two adjacent batteries is not less than 2mm. This structure requires the use of plastic bracket to fix the battery.

4. Pack battery factory uses slotted nickel strip in spot welding. The size of nickel strip meets the requirements of high current discharge. The material of nickel strip ensures low internal resistance. The spot welding machine ensures stable operation. The welding needle ensures quality. The operator can work after training and passing the examination. After spot welding, check whether the welding spot is firm. In addition, vibration tests were carried out for each batch of products to verify the anti vibration performance.

5. Different batches of batteries are made into typical finished products and life tests are carried out. When the experience of lithium battery pack design specification is summarized, the battery finished products are tested to get the actual cycle life.

6. Verify the high and low temperature performance of the battery. The cells of different pack lithium battery manufacturers are made into finished products, and different rate discharge tests are carried out at high and low temperature to obtain the actual discharge curve.

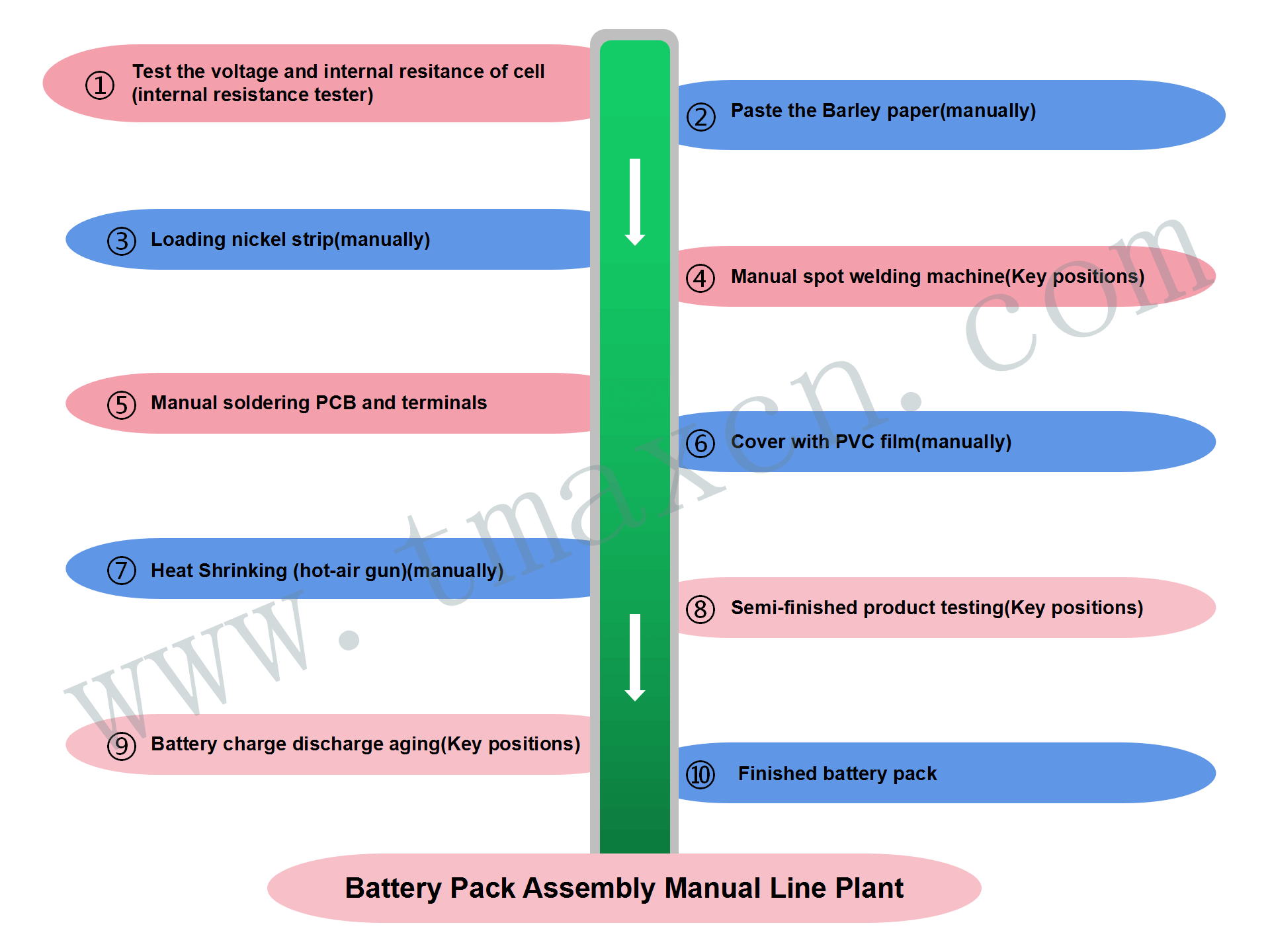

Manual Line Configuration Scheme:

Battery Sorting |

Spot Welding

|

Tin Solder |

Blow Molding |

Aging of finished products |

Daily productivity |

Staffing |

|

Scheme 1 (Initial stage)

|

(1set) |

Manual DC 5000A/8000A Gantry Spot Welder (1set) |

Electric FERROCHROME (1 PC)

|

Hot Air Gun (1PC) |

(5 channel) |

3000pcs 18650 cells |

5-8 |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com