products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Programmable Control Spin Coater with Optional Disposable Pot Lining

Model Number:

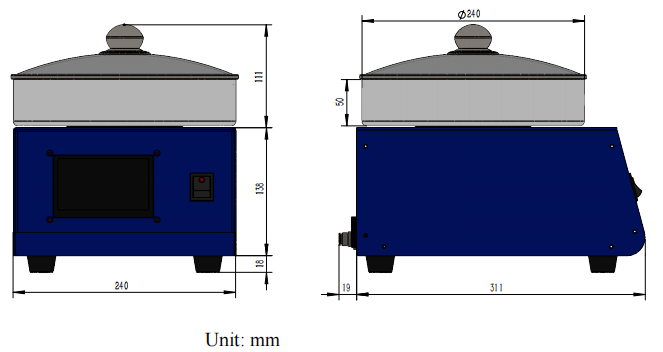

TMAX-4BCDimension(L*W*H):

210mm(W)X220mm(D)X160mm(H)Net Weight:

10KGCompliance:

CE CertifiedWarranty:

Two Years limited warranty with lifetime supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab High-speed Spin Coater Equipped with Anti-glue Intrusion ModuleNext:

Lab High Automation Spin Coater Suitable for Flexible Substrates

Programmable Control Spin Coater with Optional Disposable Pot Lining

Key Features:

1. Human machine interface 4.3 inch touch screen.

2. Prevent anti-flying piece protection and alarm.

3. Prevent anti-adhesive protection and alarm .

4. Automatic pick-up alert function.

5. Set data Unlimited group data, each group of 10 speeds

6. Optional disposable pot lining: easy to clean up the waste liquid after coating.

Plate holder size:

5mm, 10mm, 15mm, 20mm, 25mm, 50mm, 75mm, 100mm.

Please select three of these sizes. Note that the size of the plate holder should be the same as that of the sample. If the plate holder is too small, the vacuum suction force will be insufficient, causing the film to fly off; if it is too large, the solution will be sucked into the equipment by the vacuum during spin coating, leading to equipment damage.

Spin Coater Specifications

Applicable substrate |

5-120mm silicon wafers and other materials (5 inches) |

Film speed range |

50-10000RPM |

Acceleration range |

10-10000RPM/S, adjustable |

Coating time |

The time can be set arbitrarily without limit |

Man-machine interface |

4.3 inch color touch screen |

Coating cavity (material) |

Stainless steel glue pot |

Vacuum cups (material) |

Aluminum alloy (free three sizes of suction cups, size 5-120mm customer choice) |

Speed accuracy and stability |

±1RPM |

The uniformity of the glue |

Plus or minus 1% |

Direction of rotation |

Reversible |

Stylus |

BAMBOO Resistance Pen (standard) |

Set data |

Unlimited group data, each group of 10 speeds(standard) |

Every time |

0-10000 seconds |

Store data |

Unlimited data |

Gluing machine power supply port |

AC100-250V |

Vacuum pump power supply port |

AC220V(standard) AC110V(optional) |

Vacuum pump model |

SC-310V oil-free vacuum pump |

Vacuum pump pumping speed |

≥50L/min |

Vacuum pump noise |

≤55DB |

Vacuum pump minimum vacuum |

-85KPA |

Glue machine power |

200W |

Vacuum pump power |

180W |

Dimensions(Spin Coater) |

210mm(W)X220mm(D)X160mm(H) |

Dimensions(Vacuum pump) |

185mm(L)*100mm(W)*210mm(H) |

Homogenizer weight |

10KG |

Pump weight |

4.5 KG |

Relative humidity |

< 85% |

Ambient temperature |

0 to 40 ℃ |

Warranty period |

1 year |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com