products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

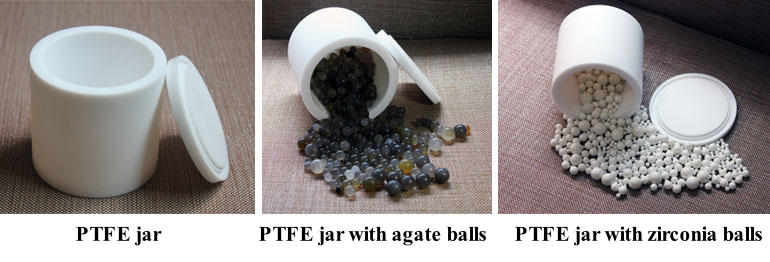

PTFE Grinding Jars with Corrosion Resistance and Non-Stick Properties

Model Number:

TMAX-PTFEjarDimension(L*W*H):

63*63*65 (mm)Net Weight:

35KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Stainless Steel Vacuum Ball Mill Jar for Planetary Ball Mill MachineNext:

PU Planetary Grinding Jar for Electronic and Battery Material Applications

PTFE Grinding Jars with Corrosion Resistance and Non-Stick Properties

Product Introduction

Polytetrafluoroethylene (Teflon or PTFE), commonly known as "the king of plastics", is a high molecular compound formed by the polymerization of tetrafluoroethylene. It possesses excellent chemical stability, corrosion resistance, sealing property, high lubrication and non-stickiness, electrical insulation, and good resistance to aging and wear. The Polytetrafluoroethylene Grinding Vessel is professionally designed, made of selected polytetrafluoroethylene materials, and processed as a whole.

Product features

1. High temperature resistance: The working temperature can reach up to 250℃.

2. Low temperature resistance: It has excellent mechanical toughness; even when the temperature drops to -196℃, it can maintain a 5% elongation rate.

3. Corrosion resistance: It shows inertness towards most chemical substances and solvents, and can withstand strong acids, strong alkalis, water, and various organic solvents.

4. Weather resistance: It has a better aging life than plastics.

5. High lubricity: It is the material with the lowest friction coefficient among solid materials.

6. Non-adhesion: It has the smallest surface tension among solid materials and is not prone to adhering to any substances.

7. Non-toxic: It has physiological inertness and, as an artificial blood vessel or organ, has no adverse reactions when implanted in the body for a long term.

Product picture

Product parameter

Parameters of PTFE Mill Jar |

|||

Model |

External Diameter |

Inner Diameter (mm) |

Height (mm) |

25ml |

63 |

31 |

65 |

50ml |

63 |

43 |

59 |

100ml |

68 |

48 |

76 |

250ml |

88 |

68 |

98 |

500ml |

108 |

88 |

115 |

1L |

133 |

109 |

142 |

1.5L |

133 |

109 |

178 |

2L |

158 |

134 |

172 |

2.5L |

158 |

134 |

202 |

3L |

158 |

138 |

210 |

4L |

178 |

158 |

226 |

5L |

218 |

190 |

217 |

10L |

246 |

218 |

307 |

15L |

273 |

243 |

372 |

20L |

320 |

285 |

359 |

25L |

320 |

285 |

424 |

We can customize PTFE jars of various specifications and sizes according to customer requirements.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588