products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Roll to Roll Automatic Electrode Slitting Machine for Battery Electrode Production

Model Number:

TMAX-WHFT-500Compliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Roll-to-Roll Electrode Slitting Machine for Lithium Battery Cathode/Anode Electrode Sheets CuttingNext:

Roll to Roll Battery Electrode Automatic Slitting Machine for Lithium Battery

Roll to Roll Automatic Electrode Slitting Machine for Battery Electrode Production

1. Equipment Overview

1.1 Equipment Functions

No. |

Item |

Technical Specifications |

Remarks |

1 |

Applicable Materials |

Electrode sheets after coating and calendaring: LFP, LCO, LMO, NCM, NCA, LTO, graphite, etc. |

|

2 |

Substrate Specifications |

Aluminum foil (AL): Thickness 9–30μm, Width 50–500mm, Max. roll diameter: 400mm |

|

Copper foil (Cu): Thickness 6–30μm, Width 50–500mm, Max. roll diameter: 400mm |

|

||

3 |

Roller Width Design |

650mm |

|

4 |

Guaranteed Slitting Width |

30–500mm |

|

5 |

Mechanical Running Speed |

50m/min |

|

6 |

Slitting Speed |

1–40m/min |

Depends on slitting quality |

7 |

Electrode Thickness Range |

70–250μm |

|

8 |

Slitting Method |

1. Combined rotary blade slitting; 2. Nishimura-type cutter structure; 3. Spec to be defined |

|

9 |

Rewinding Method |

Dual-shaft differential shaft staggered rewinding |

|

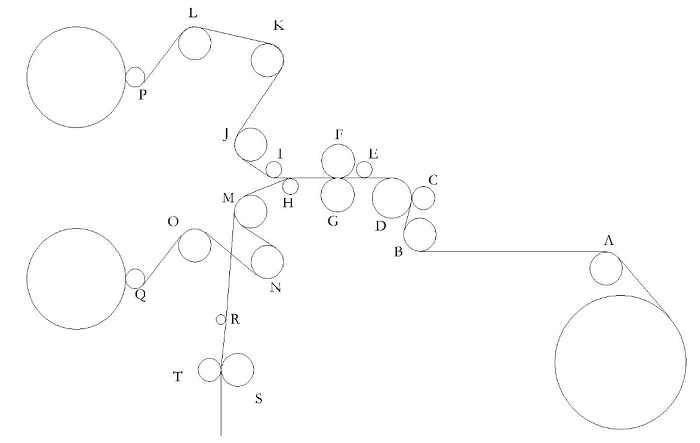

1.2 Working Principle

Coiled positive and negative electrode sheets, post-calendaring, are loaded into the unwinding system. Driven by traction, the electrode sheet is fed into a set of blades arranged to meet process requirements for slitting. The slit sheets are rewound by upper and lower rewinding systems, with edge trims collected through a dedicated trim collection system.

The machine is outfitted with automatic web guiding, tension control, and dust extraction systems (including dust extraction in the blade area). These features ensure smooth material feeding, stable slitting performance, and adherence to specifications for burrs and straightness.

1.3 Operating Workflow

Load the material onto the unwinding shaft using a transfer trolley, then route it through the splicing table, traction rollers, slitting blade group, and roller group, before guiding it to the upper and lower differential shafts. After that, handle trim rewinding, set the required tension, switch the web guiding system to automatic mode, and press the start button—the machine will then automatically perform slitting and rewinding.

1.4 Overall Structure

Approximate Dimensions:

· Main Machine: 1800mm (L) × 2300mm (W) × 1900mm (H)

· Dust Collector: 800mm (L) × 800mm (W) × 1400mm (H)

· Blade Cart: 1200mm (L) × 400mm (W) × 1000mm (H)

1.5 Major Component Structure

1.5.1 Unwinding System

No. |

Item |

Description |

1 |

Unwinder |

Single-shaft center unwinding; 3" core; Max. roll dia. 400mm; width ≤ 500mm |

2 |

Splicing Table |

Dual pneumatic pressing rod type |

3 |

Web Guiding |

Ultrasonic servo-guided; stroke ±40mm; accuracy ±0.2mm |

4 |

Tension System |

Fully automatic torque closed-loop control; adjustable 0–250N |

1.5.2 Slitting Mechanism

No. |

Item |

Description |

1 |

Mechanical Speed |

Max. 50m/min |

2 |

Slitting Speed |

0–40m/min |

3 |

Slitting Method |

Combined rotary blades; Nishimura-type structure; specs to be finalized |

4 |

Blades |

Material: tungsten alloy; Upper blade: Φ100×Φ65×0.7mm (35°), Lower blade: Φ100×Φ65×2.0mm (90°) |

Blade life: Positive electrode: 150–200k meters, Negative electrode: 250–300k meters; reusable 10x |

||

5 |

Blade Adjustment |

Adjustable blade clearance; engagement via screw threads |

6 |

Blade Drive |

Servo motor; adjustable blade speed percentage via control panel |

7 |

Cleaning Device |

Direct-discharge brush at lower blade |

8 |

Slitting Width Accuracy |

≤±0.1mm |

9 |

Electrode Snake Error |

≤±0.3mm/1000mm |

10 |

Metal Burrs |

Longitudinal: <6μm; Transverse: <10μm |

1.5.3 Rewinding System

No. |

Item |

Description |

1 |

Rewind Shafts |

Dual-axis staggered rewinding; slip-shaft; 3" core; Max. dia. 400mm; single loop 40mm |

2 |

Rewinding Accuracy |

≤±0.4mm |

3 |

Pressure Rollers |

Gravity rollers (75mm); pneumatic open/close; other sizes optional |

4 |

Dust Collection |

Dual brush cleaning (upper/lower); stepper-driven brushes; integrated ducting; blade zone extraction |

5 |

Edge Trim Unit |

Dual servo-driven systems; torque adjustable; trim >5mm; collected into bins |

1.5.4 Control System

No. |

Item |

Description |

1 |

Main Control Unit |

1. Rotatable centralized control panel; 2. OMRON main controller with Ethernet; 3. All key components are imported brands. |

2 |

Electrical Cabinet Layout |

1. Partitioned layout management; 2. Separate zones for mechanical, pneumatic, and electrical; 3. Electrical panel isolated from dust for ease of maintenance. |

3 |

Alarm / Maintenance |

1. Equipped with tri-color warning light and buzzer; 2. Visual and audible alarms for machine start-up/abnormalities; 3. Control interface includes IO check table. |

4 |

Electrical Specs |

1. 480V / 60Hz, 3-phase (US Standard); 2. Air consumption: 13 L/h; 3. Total power: approx. 6 kW |

5 |

Machine Uptime |

≥99% (web breakage rate <1%) |

1.6 Main Components

No. |

Name |

Brand |

Origin |

1 |

PLC Unit |

Omron |

Japan |

2 |

Touch Screen |

Panel Master |

China |

3 |

Tension Control System |

Kruida |

China |

4 |

Web Guiding System |

Kruida |

China |

5 |

Inverter |

Mitsubishi |

Japan |

6 |

Low Voltage Circuitry |

Schneider |

France |

7 |

Inverter Motor |

CP |

China |

8 |

Servo Motor |

Mitsubishi |

Japan |

9 |

Stepper Motor |

Yankon |

China |

10 |

Pneumatic Components |

Airtac |

Taiwan, China |

11 |

Electro-Pneumatic Valve |

SMC |

Japan |

12 |

Proximity Switch |

DCF |

China |

13 |

Linear Guide |

PMI |

Taiwan, China |

14 |

Bearings |

NSK / Local |

Japan / China |

15 |

Planetary Gearbox |

Dexco |

China |

16 |

Coupling |

GZD |

China |

17 |

Differential Shaft |

Custom-made |

China |

18 |

Blades |

Shengong / Oulin |

China |

Included Accessories (Per Unit)

No. |

Name |

Model |

Qty |

Unit |

Remarks |

1 |

Hydraulic Blade Cart |

FT500 Special |

1 |

set |

|

2 |

Blade Assembly |

FT500 Special |

1 |

set |

|

3 |

Hydraulic Lift Cart |

FT500 Special |

1 |

set |

|

4 |

Pressure Roller Assembly |

70mm |

6 |

sets |

Others optional |

5 |

Upper Blades |

Φ100×Φ65×0.7mm |

10 |

pcs |

Others optional |

6 |

Lower Blades |

Φ100×Φ65×2.0mm |

10 |

pcs |

Others optional |

7 |

Blade Spacers |

19mm |

10 |

pcs |

Others optional |

8 |

Spacer Set |

TBD |

1 |

set |

Others optional |

9 |

Hook Spanner |

C32 |

1 |

pc |

For blade replacement |

10 |

V-Type Blade Base |

— |

2 |

pcs |

For blade replacement |

11 |

Dust Collector |

WHXC-2200 |

1 |

set |

|

12 |

Standard Tool Kit |

Hex keys, screwdrivers |

1 |

set |

|

13 |

User Manual |

— |

1 |

copy |

|

14 |

Accessory Manuals |

— |

4 |

copies |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com