products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

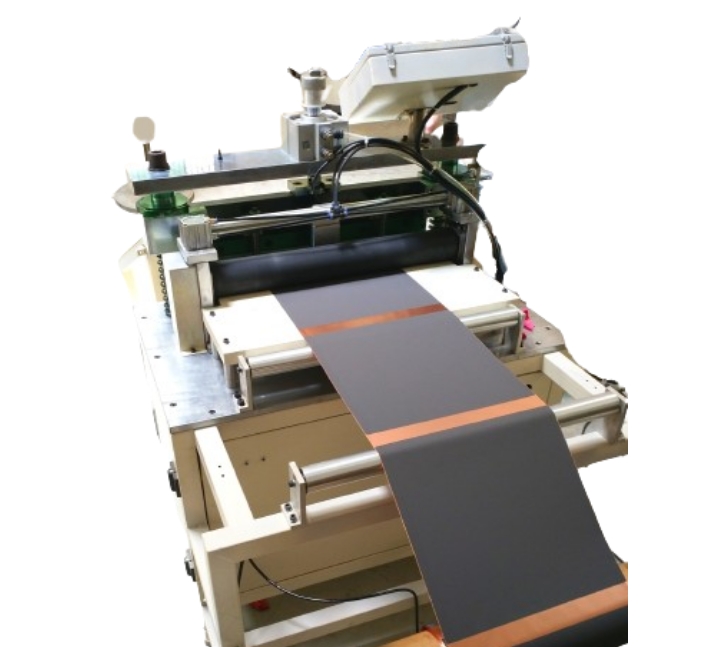

Sodium-Ion Battery Electrode Sheet Cross Cutting Machine

Model Number:

TMAX-CPJ-500Compliance:

CE CertifiedWarranty:

Two year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Sodium-ion Na-ion Battery Production Line Turn Key SolutionNext:

Sodium-Ion Laboratory Battery Electrode Slitting Machine

Sodium-Ion Battery Electrode Sheet Cross Cutting Machine

I. Overview:

This machine is suitable for precise cutting of the fixed length and tracking of the coated cathode and anode rolls of secondary lithium-ion batteries (applicable for cutting after continuous or intermittent coating), resulting in neatly trimmed edges without burrs or powder detachment. It is an important piece of equipment in the production process of the lithium-ion battery industry.

II. Working Principle:

The machine unrolls the material using a tension controller and the stepping motor drives precision feed rollers to achieve fixed-length feeding. An imported high-accuracy color mark sensor ensures tracking and control for positioning and intermittent cutting, with the cylinder executing the cut.

This machine adopts an industry-original four-post guide and innovative tool design, effectively ensuring the cutting accuracy, stability, and service life. It is equipped with well-known brand components and PLC control, with a color touch screen for operation, providing a user-friendly interface and ease of use, and high control precision of cutting. It can set processing batches, quantity, and automatic stoppage upon completion of processing.

III. Specification

Maximum Power |

1.5KW |

Maximum Cutting Width |

500mm |

Fixed Length Accuracy |

±0.3mm (up to ±0.1mm) |

Cutting Length |

1mm to 10M |

Positioning Accuracy |

±0.3mm |

Cutting Speed |

0 to 4000 cuts/hour |

Machine Weight |

Approximately 380Kg |

Dimensions |

L1000 × W1100 × H1000 (mm) |

Casing Material |

Galvanized steel plate with surface powder coating |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com